Length and Position Measurement

advertisement

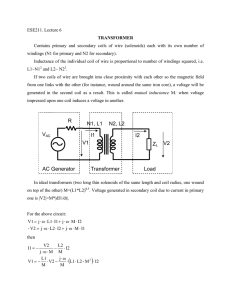

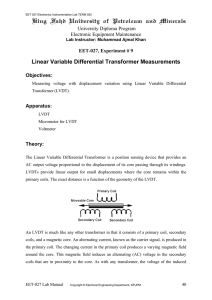

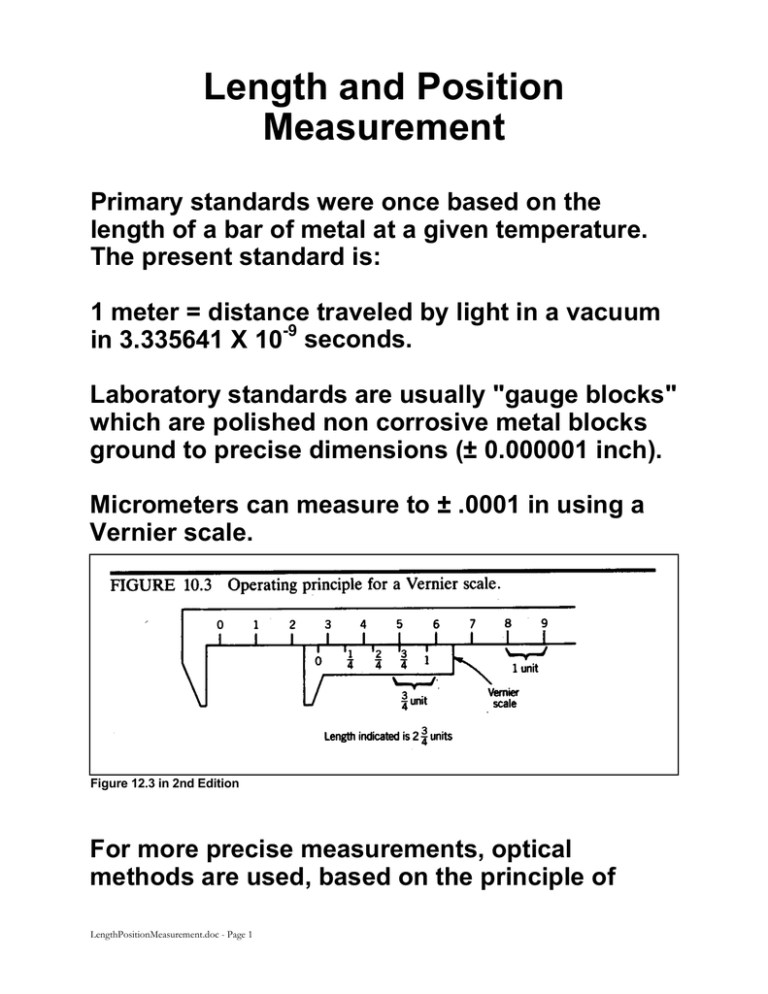

Length and Position Measurement Primary standards were once based on the length of a bar of metal at a given temperature. The present standard is: 1 meter = distance traveled by light in a vacuum in 3.335641 X 10-9 seconds. Laboratory standards are usually "gauge blocks" which are polished non corrosive metal blocks ground to precise dimensions (± 0.000001 inch). Micrometers can measure to ± .0001 in using a Vernier scale. Figure 12.3 in 2nd Edition For more precise measurements, optical methods are used, based on the principle of LengthPositionMeasurement.doc - Page 1 interferometry. Figure 12.7 in 2nd Edition LengthPositionMeasurement.doc - Page 2 The interferometer works by measuring the light and dark fringes produced by interference of two light beams. The precision is related to the wavelength of the light. Interferometers using visible laser light can measure distances with a precision of ± . 000001 in. The output can also be converted to an electrical signal using photodiodes. LengthPositionMeasurement.doc - Page 3 Displacement Measurement The potentiometer (pot) is a coil of wire with a sliding contact (wiper) which divides the resistance of the coil into two parts. By placing a voltage across the coil and measuring the voltage from one end to the sliding contact, the position can be calculated. Figure 12.8 in 2nd Edition LengthPositionMeasurement.doc - Page 4 The LVDT (Linear Variable Differential Transformer) uses a movable magnetic core to induce a voltage in two secondary coils by the principle of induction. Figure 10.9 Construction of an LVDT LengthPositionMeasurement.doc - Page 5 Figure 12.9 in 2nd Edition The LVDT has better resolution (± 0.00001 in) than the potentiometer, but the linear range is more limited. Both the LVDT and potentiometer are subject to "loading" errors, which we will discuss later. Figure 10.10 in 2nd Edition LengthPositionMeasurement.doc - Page 6 LVDT Theory of Operation An LVDT is much like any other transformer in that it consists of a primary coil, secondary coils, and a magnetic core. An alternating current, known as the carrier signal, is produced in the primary coil. The changing current in the primary coil produces a varying magnetic field around the core. This magnetic field induces an alternating (AC) voltage in the secondary coils that are in proximity to the core. As with any transformer, the voltage of the induced signal in the secondary coil is linearly related to the number of coils. The basic transformer relation is: (1) where: Vout is the voltage at the output, Vin is the voltage at the input, Nout is the number of windings of the output coil, and Nin is the number of windings of the input coil. As the core is displaced, the number of coils in the secondary coil exposed to the coil changes linearly. Therefore the amplitude of the induced signal varies linearly with displacement. LengthPositionMeasurement.doc - Page 7 The LVDT indicates direction of displacement by having the two secondary coils whose outputs are balanced against one another. The secondary coils in an LVDT are connected in the opposite sense (one clockwise, the other counter clockwise). Thus when the same varying magnetic field is applied to both secondary coils, their output voltages have the same amplitude but differ in sign. The outputs from the two secondary coils are summed together, usually by simply connecting the secondary coils together at a common center point. At an equilibrium position (generally zero displacement) a zero output signal is produced. The induced AC signal is then demodulated so that a DC voltage that is sensitive to the amplitude and phase of the AC signal is produced. Magnetostriction A pulse is induced in a specially-designed magnetostrictive waveguide by the momentary interaction of two magnetic fields. One field comes from a movable magnet which passes along the outside of the sensor tube, the other field comes from a current pulse or interrogation pulse launched along the waveguide. The interaction between the two magnetic fields produces a strain pulse, which travels at sonic speed along the waveguide until the pulse is detected at the head of the sensor. The position of the magnet is determined with high precision by measuring the elapsed time between the launching of the electronic interrogation pulse and the arrival of the strain pulse. As a result, accurate non-contact position sensing is achieved with absolutely no wear to the sensing components. LengthPositionMeasurement.doc - Page 8 LengthPositionMeasurement.doc - Page 9