INSTALLATION INSTRUCTION 300 System C

advertisement

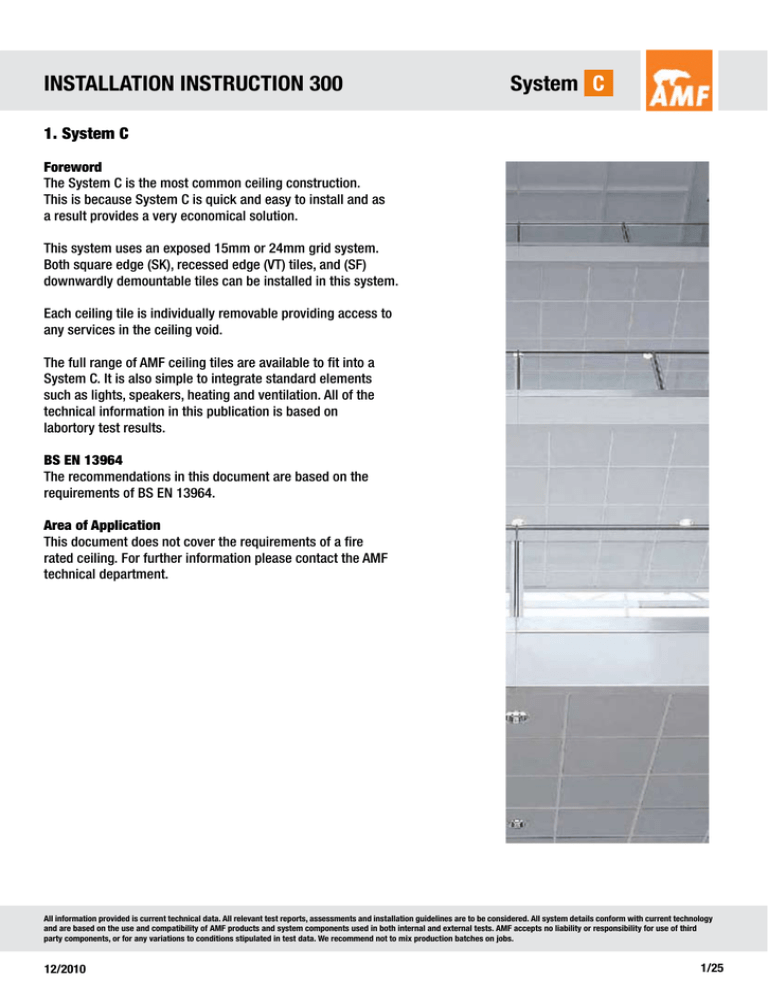

INSTALLATION INSTRUCTION 300 System C 1. System C Foreword The System C is the most common ceiling construction. This is because System C is quick and easy to install and as a result provides a very economical solution. This system uses an exposed 15mm or 24mm grid system. Both square edge (SK), recessed edge (VT) tiles, and (SF) downwardly demountable tiles can be installed in this system. Each ceiling tile is individually removable providing access to any services in the ceiling void. The full range of AMF ceiling tiles are available to fit into a System C. It is also simple to integrate standard elements such as lights, speakers, heating and ventilation. All of the technical information in this publication is based on labortory test results. BS EN 13964 The recommendations in this document are based on the requirements of BS EN 13964. Area of Application This document does not cover the requirements of a fire rated ceiling. For further information please contact the AMF technical department. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 1/25 INSTALLATION INSTRUCTION 300 System C 1.1 System construction Main runner distance 1200/1250mm The Layout used depends on the weight of the panels to be used (see page 5 for weights). 3 4 6 5 1 2 10 9 Material requirements The quantities and recommended installation times are estimates only. The figures do not include an allowance for waste. 600 x 600 625 x 625 600 x 1200 625 x 1250 300 x 1200 312.5 x 1250 300 x 1800 300 x 2500 400 x 1200 400 x 2500 Requirements for each m² of ceiling surface AMF-Mineral ceiling tiles 1 pcs. 2.78 2.56 1.39 1.28 2.78 2.56 1.86 1.34 2.09 1.00 AMF-Metal ceiling tiles 1 pcs. 2.78 2.56 1.39 1.28 2.78 2.56 Main runner PH 375 2 lin.m Main runner PH 360 2 lin.m 0.84 Hanger 3 pcs. 0.67 Grid sizes in mm PH 30/31.25 Cross tee lfdm. PH 40 Cross tee lin.m 0.80 0.80 0.84 0.67 0.67 0.80 0.84 0.67 0.67 3.34 3.34 0.67 2.50 0.84 1.85 1.85 0.56 0.40 0.67 1.67 0.40 PH 60/62,5 Cross tee 4 lin.m 0.84 0.80 PH 120/125 Cross tee 5 lin.m 1.67 1.60 1.67 1.60 3.34 3.20 pcs. 5.56 5.12 2.78 2.56 5.56 5.12 3.70 2.67 4.16 2.00 lin.m 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60 pcs. 1.20 1.20 1.20 1.20 1.20 1.20 DF (optional) Hold down clip 2.50 RWL edge trim or A-RWU edge runnter for metal tiles KRF (metal) border clip 6 Hanger centre´s 9 m 1.25 1.20 1.25 1.20 1.25 1.20 1.80 1.80 1.25 1.50 Distance beteween main runners Perimeter trim fixing centre´s 10 m 1.20 1.25 1.20 1.25 1.20 1.25 0.30 0.30 1.20 0.40 m 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 0.40 min 25 25 23 23 33 33 33 33 33 33 Fitting time required for installation Advice The recommended minimum void depth for a standard installation is 120mm, however a depth of greater than 150mm is preferred. If a shallower void depth is required use the AMF (SF) edge detail which will be fully demountable. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 2/25 INSTALLATION INSTRUCTION 300 System C 1.2 System build Main runner distance 600/625mm The Layout used depends on the weight of the panels to be used (see page 5 for weights). 3 6 4 10 1 2 10 9 Material requirements The quantities and recommended installation times are estimates only. The figures do not include an allowance for waste. 600x600 625x625 600x1200 625x1250 Requirements for each m² of ceiling surface AMF-Mineral ceiling tiles 1 Stk. 2.78 2.56 1.39 1.28 AMF - Fibrafutura ceiling tiles 1 Stk. 2.78 2.56 1.39 1.28 Main runner C-PH 3750 2 lfdm. Main runner C-PH 3600 2 lfdm. 1.67 Hangers 3 Stk. 1.85 1.78 1.85 1.78 C-PH 60/62.5 Cross tee 4 lfdm. 1.67 1.60 0.84 0.80 Stk. 5.56 5.12 2.78 2.56 Grid sizes in mm C-DF (optional) hold down clip 1.60 1.60 1.67 C-RWL edge trim 6 lfdm. 0.60 0.60 0.60 0.60 Hanger centre´s 9 m 0.90 0.90 0.90 0.90 Main runner centre´s 10 m 0.60 0.63 0.60 0.63 m 0.40 0.40 0.40 0.40 min 30 30 28 28 Perimeter trim fixing centre´s Fitting time required for picking and packing Advice The recommended minimum void depth for a standard installation is 120mm, however a depth of greater than 150mm is preferred. If a shallower void is required use the AMF (SF) edge detail which will be fully demountable. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 3/25 INSTALLATION INSTRUCTION 300 System C 2. General Transport and storing The ceiling tiles should be installed in a dry environment, the cartons should be stacked on a flat surface to avoid damage. Handling Care is needed when manually handling the cartons to prevent damage to the tiles. The cartons must not be dropped or thrown and they must not be stored on their edges or at any angle. When handling the ceiling tiles themselves, clean gloves are recommended to prevent marking the surface. Fitting condition The room where the ceiling tiles are to be installed should be dry and clean. All external doors and glazing should be installed and it is preferable that the heating system is in operation and a normal work temperature of 15-20°C be provided. If the humidity is above 70% it is not usually reommended to install the ceiling tiles. In high humidity situations please contact the AMF technical department for advice. In environments with permanently high humidity, please contact the AMF technical department for advice. Anticorrosive substructure All of the standard exposed grid components meet the requirements of exposure class B (BS EN 13964). If there is a requirement to resist higher humidity than this, components should be selected to meet exposure class C or D as required. Exposure classes to BS EN 13964 2004 Category A Up to 70% relative humidity. up to 25°C but without corrosive pollutants B Up to 90% relative humidity, up to 30°C but without corrosive pollutants C Over 90% relative humidity and risk of condensation D More severe than above All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 4/25 INSTALLATION INSTRUCTION 300 System C 3. System components 3.1 Ceiling tiles: Thickness weights and available edge details Standard Thermatex Thermatex Thermatex Thermatex SK 15/24 d=15mm 4.5kg / m² d=19mm 5.7kg / m² d=24mm 7.2kg / m² d=40mm 12.0kg / m² Acoustics Th. Alpha Th. Alpha coloured Th. Thermofon Th. Acoustic Th. Acoustic RL Th. SF Acoustic Th. dB Acoustic 24mm Th. dB Acoustic 30mm Kombimetal VT-S 15/24 Material+Design Thermatex Symetra Metal Symetra Wood Symetra Fibrafutura VT- 15/24 Grid Construction 24mm table grid including hangers VT 15/24 VT-S15F d=19mm 3.0kg / m² d=19mm 3.0kg / m² d=15mm 2.4kg / m² d=19mm 4.6kg / m² d=19mm 5.8kg / m² d=24mm 8.4kg / m² d=24mm 8.4kg / m² d=30mm 10.5kg / m² d=19mm 9.0kg / m² SF Edge long side d=15mm d=0.5-0.7mm d=12mm d=25mm VT-S 15/24 SF Edge short side 5.5kg / m² 5.5kg / m² 10.5kg / m² 11-13kg / m² SK 15/24, VT 15/24 SK 15/24, VT 15/24 SK 24, VT 24 SK 24 Edges: Mineral Fibre. Wood SK 15/24, VT-S 15/24 SK 15/24 SK 15/24 SK 15/24, VT 15/24 SK 15/24, VT 15/24 SF SK 15/24, VT 15/24 SK 15/24 VT 24 Edges: Mineral Fibre SK 15/24, VT 15/24, VT-S 15 SK 15/24, VT 15/24, VT-S 15/24 VT-S 15F SK 15/24, VT 15/24 SK 15/24 2.5kg / m² Data sheets Data sheets are available for all ceiling tiles these contain full information on the technical performance of the systems. Advice Special size tiles and edge details are available to order, please contact the AMF technical department for advice. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 5/25 INSTALLATION INSTRUCTION 300 System C 3.2 Grid system Exposed grid system with 24mm wide grid sections. Both main runners and cross tees are manufactured from high quality electro galvanised steel with a steel capping in white. 38 24mm universal main runner 24mm cross tee 24mm cross tee 6.5 Maximum deflection for the grid system according to BS EN 13964 l/500 = 2.5mm max 11 Performance system 24 qmax = 8.0 kg/m² (1250x1250) qmax = 9.9 kg/m² (1200x1200) 24mm universal main runner 24mm cross tee 24mm cross tee max. 1250mm 625 24mm Universal main runner 3600/3750 UNI PH T24/38 - 3600 UNI PH T24/38 - 3750 6.5 Maximum deflection for the grid system according to BS EN 13964 l/500 = 2.5mm max 38 Performance Click 625 11 24mm cross tee 24mm cross tee 24mm cross tee max. 1250mm 24 24mm Cross tee 600/625 UNI PQ Click T24/38 - 600 UNI PQ Click T24/38 - 625 qmax = 8.0 kg/m² (1250x1250) qmax = 9.9 kg/m² (1200x1200) max. 1250mm max. 1250mm 24mm Cross tee 1200/1250 UNI PQ Click T24/38 - 1200 UNI PQ Click T24/38 -1250 625 625 All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 6/25 INSTALLATION INSTRUCTION 300 System C 3.3 Hangers Fast hanger with loop/clasp Item SoS 100 - 300 SoS 300 - 600 SoS 600 - 1000 SoS 1000 - 1250 SoS 1250 - 1500 SoS 1500 - 1750 A SoS or SoH A:drop 100 - 330 mm 320 - 590 mm 520 - 990 mm 650 - 1260 mm 760 - 1480 mm 900 - 1760 mm DoS or DoH Spring hanger with wire hook Item L: length Maximum load 25kg SHD 125 125 mm SHD 250 250 mm L SHD DoS or DoH Hanger clickfix II with tension spring Item L: length BS 10 110 mm L Nonius hanger bottom part Item Anu 24 Maximum load 25kg Item DAH Sti L A: drop 85 mm 135 mm 235 mm 340 mm Anu L: length 190 mm Maximum load 25kg Direct hanger L DAH Ano L: length 40 mm Nonius hanger top part and bottom part Item A: drop SAH 5 (40/80) 45 - 75 mm SAH 5 (60/100) 55 - 100 mm SAH 5 (80/120) 85 - 130 mm SAH Sti A Nonius hanger top part Item Ano 115 Maximum load 25kg Ano 120 Ano 130 Ano 140 A BS 10 Maximum load 25kg Maximum load 25kg All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 7/25 INSTALLATION INSTRUCTION 300 System C 3.3.1 Hanger accessories/fitting L Hanger wires with loop DoS with hook DoH DoS DoH Item L: length DoS / DoH 125 125 mm DoS / DoH 250 250 mm DoS / DoH 375 375 mm DoS / DoH 500 500 mm DoS / DoH 750 750 mm Fitting Hangers should be fixed directly vertically however it is possible to use angled hangers but additional hangers and bracing may be required, please contact the AMF technical department for advice. Maximum hanger centres are 1200mm (600mm module) or 1250mm (625mm module). Each main runner joint must have a hanger within 150mm of the joint. Suspension depths of up to 3,000mm can be accommodated with fast hangers or wire hangers, for suspension depths over 3,000mm the nonius hanger or pre-straightened galvanized steel wire is recommended. A combination of several tension springs as extension are not recommended. Hangers subjected to compression. In normal situations the hangers are in tension. In applications where the ceiling may be subject to compression forces nonius hangers must be used with two pins for security. X Hangers under compression In normal situations the hangers are subject to loads (downward forces) and therefore under tension (ceiling tiles, grid lighting etc.) In special applications where the ceiling may be subject to compression (upward forces), nonius hangers must be used (upper + lower) with two fixings for security (refer to page 7). Fire rated ceilings For fire rated applications please contact the AMF technical department. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 8/25 INSTALLATION INSTRUCTION 300 System C 3.3.2 Perimeter hangers Minimum distances To avoid overloading the perimeter trim, the first hanger must be positioned at a minimum distance from the wall. This distance varies with the system weight. Material Tile thickness Thermatex d = 15 mm Thermatex d = 19 mm Thermatex d ≥ 19 mm Kombimetal Metal tiles Wood tiles Distance X 450 mm 300 mm 150 mm 150 mm 150 mm 150 mm X All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 9/25 INSTALLATION INSTRUCTION 300 System C 3.4 Perimeter Trim The standard perimeter trim is a white wall angle 19 x 24 x0.5mm (24x24x0.5mm), mitred at the corners. For the shadow edge detail, the shadow trim 25x15x8x15mm can be used. The perimeter tiles are cut and lay in. 8 15 15 24 Ref. Number 24 RW L19/24 RW L24/24 SRW 25x15x8x15 SRW 25x15x8x15 SRW 20x20x20x20 RW L 24/24 24 SRW 20x20x20x20 20 20 Lenght 3.05mm 3.05mm 3.05mm 3.05mm 25 Thickness Wall Angle 19/24 0.5mm Wall Angle 24/24 0.5mm Shadow Trim 25/15/8/15 0.5mm Shadow Trim 20/20/20/20 0.7mm RW L 19/24 19 Options For the perimeter of the ceiling. several options are available: 15 15 Support The grid is laid out so that it is supported on at least 2/3 of the horizontal leg of the perimeter trim. This applies to both main runners and cross tees. 24 ≥16 The perimeter cut tiles should be cut to the same dimensions. ≥16 24 Fixings Generally installation has to be carried out with approved fixings suitable for the type of wall being fixed to. The maximum fixing centres are 400mm. Flat headed screws are recommended to prevent deformation of the trim. The grid should be supported on at least 2/3 of the horizontal leg of the perimeter trim 00mm max 4 Corners The trim should be mitred in both external and internal corners. An alternative is to use preformed mouldings to suit the trim. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 10/25 INSTALLATION INSTRUCTION 300 System C Perimeter Trim L shaped wall angles with square edge (SK) tile This is a standard construction. The grid and tiles must be supported on at least 2/3 of the perimeter trims horizontal leg. Shadow trim with square edge (SK) tile This is an alternative construction. The tile and grid are both supported on the lower leg of the trim providing a shadow gap detail around the perimeter. The grid and tiles must be supported on at least 2/3 of the perimeter trims lower horizontal leg. Shadow trim with recessed edge (VT) tile The grid construction is supported on the higher leg of the 25x15x8x15mm trim. The tiles are supported on the lower edge. There are filler pieces available to fill the gap between the tiles. Alternative for recessed edge (VT) tile An alternative construction is to use the VT edge tiles on an L-shaped wall angle. It is possible to reform the edges using an appropriate rotary cutter and then repaint the edges. Alternatively the perimeter rebate can be reformed to a simple step rebate using a sharp blade hand tool. In both these situations the grid and the perimeter trim are installed at the same level. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 11/25 INSTALLATION INSTRUCTION 300 System C 3.5 Accessories There are many solutions available to allow air exchange between the room and the ceiling void which may be required for various reasons. 3.5.1 Shadow trim with ventilation slots Open area of ventilation slots: approx 44cm² per linear metre. Available in the following trims: Shadow trim 20/20/12/20 Shadow trim 20/20/20/20 d = 0.6mm d = 0.75mm L = 3.00m L = 4.00m 3.5.2 Perimeter trims fixed to blocks For L shaped wall angles and shadow trims. The blocks can be formed from wood or other material. The fixing centres are reduced to 200mm and the fixing blocks must be at least 100mm wide. 100mm m max. 200m Open area of ventilation slots: approx 200cm² per linear metre. 3.5.3 Light and ventilation grilles An alternative is to use grill type materials at the perimeter to provide the ventilation. This solution can provide much higher levels of open areas. The panels are simply laid into the grid system and take the place of the perimeter ceiling tiles. A range of panel types are available in a variety of materials and module sizes. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 12/25 INSTALLATION INSTRUCTION 300 System C Accessories 3.5.4 Filler Pieces Filler pieces can be installed to close the small gap produced when using shadow trim. The filler pieces are available in the following edge details: ∙ VT-24 ∙ VT-15 Filler piece Shadow Trim SRW 25x15x8x15 Cut Tile Edge VT Edge Option 3.5.5 Internal and External Mitres As an alternative to mitring the corner joints, preformed mouldings are available to save installation time. Internal and external mitres for L- Trim 19/24 or 24/24 Internal corner The mitres are simply slid on the corners. External corner Internal and External mitre for Shadow Trim SRW 25/15/8/15 The shadow trim mouldings have metal lugs which are bent over to secure them in place. Internal corner External corner All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 13/25 INSTALLATION INSTRUCTION 300 System C Accessories 3.5.6 Fixing Clip To hang objects below the grid system, several different screw and decoration clips are available for both the 15mm wide and 24mm wide grid systems. Each clip should have an additional hanger from the soffit capable of carrying 16kg. 3.5.7 Hold down clip In areas with windows, doors or atriums where there is the possibility of substantial pressure differentials, the ceiling tiles can be held in place with hold down clips. After the ceiling tiles have been installed, the clips are installed onto the supporting grid section. Other applications AMF Soundmosaic 3.5.8 Soundmosaic The audio system, which works like a wide area speaker is available in all Thermatex surfaces. The neighbouring tiles are locked to the grid using hold down clips which improves the audio reflection pattern. Further information about this system is available. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 14/25 INSTALLATION INSTRUCTION 300 System C Accessories 3.5.9 Column rings When finishing suspended ceilings to columns, the use of prefabricated column rings is recommended. The aluminium rings are available with different diameters. Diameters are available from 200mm to 1000mm in 50mm increments. Colour: white similar to RAL 9010 3.5.10 Flexible wall angle When finishing ceilings to curved walls, the use of a flexible wall angle is recommended. Where the wall diameter exceeds 1000mm the wall angles can be adjusted by hand to fit the convex or concave shape. RWL Flex: Material: PVC Size 28/22.5mm Length 2,500mm RWL Flex (30/20): Material: Aluminium Size 30/20mm Length 3,000mm For radii smaller than 4.,000mm, on site painting after bending is recommended. Advice Very small radii can be difficult to form. In some cases a plasterboard transition detail should be considered. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 15/25 INSTALLATION INSTRUCTION 300 System C 3.6 Lighting/ Additional weights 3.6.1 Modular lightning When the main runners are at 1200mm/1250mm centres, two additional hangers on the 1200mm/1250mm long cross tee are required When the main runners are at 600mm/625mm centres, no additional hangers are required providing the lights weigh no more than 6kg. Additional hanger Detail Light fittings, ventilation grilles and sprinkler systems should not have more than a 5mm upstand adjacent to the grid. 3.6.2 Additional Weight Generally additional loads need to be supported with additional hangers from the soffit. Services such as downlighters and speakers etc require a pattress or frame to distribute the load on to the grid system. Loads less than 0.3kg require no additional support. 3.6.3 Installation frames A versatile installation frame is available and can be used for all common services fittings. The frame ensures that the additional weight is carried by the grid system and is not supported on the tiles. Two additional hangers are required. Additional hanger All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 16/25 INSTALLATION INSTRUCTION 300 System C B 4. Room layout / Ceiling Symmetry Modul size 600mm/625mm Arrangement The ceiling is set out from the middle of the room with the complete tiles (Tile width = B) In the example shown, the cut tile at the perimeter is very small. ≤B/2 Layout not recommended Advice If the cut tile is less than half the tile width (<B/2) it will appear aesthetically poor and therefore is not advisable. B/2 ≥B/2 ≥B/2 B/2 ≤B/2 Layout not recommended B Correct Layout Ceilings with larger cut tiles are aesthetically more pleasing and are more efficient to install. When setting out the ceiling. start from the middle. The first tile should be directly on the centre line (half the tile each side of the centre). This will always result in a perimeter cut tile greater than half the tile width. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 17/25 INSTALLATION INSTRUCTION 300 4.1 Construction Main runner distance 1200mm/ 1250mm max. 1200 max. 1200 hanger Main runner long cross tee short cross tee (for square modules) 1250 Main runner centre‘s Construction layout Module 600mm/625mm Between the main runners at 1250mm centres, a 1250mm long cross tee is fitted at 625mm centres. These cross tees are then subdivided by 625mm cross tees to form the 625mm x 625mm module layout. If the tile size is 1250mm x 625mm then the short 625mm cross tees are not required. The layout for a 600mm x 600mm module is carried out the same way except the main runners are at 1200mm centres and the cross tees are 1200mm and 600mm long. Hanger centres System C Main runner Module size 625 625 625 625 625 hanger The following construction is not recommended: This construction also known as the “ladder format” uses long cross tees parallel to the main runners. This layout can increase the deflection beyond acceptable limits. Main runner long cross tee X X Main runner short cross tee (for square modules) Main runners at 600mm/ 625mm centres 900 900 Hanger centres 900 hanger Main runner 625 short cross tee 625 Main runner centre‘s Construction layout Module 600mm/625mm This layout uses only short 600mm or 625mm cross tees and has more hangers so is able to carry a greater load. Lights up to 6kg can be supported without any additional hangers. Weights over 6kg require two additional hangers. Module size Main runner 625 625 625 625 625 All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 18/25 INSTALLATION INSTRUCTION 300 System C 4.2 Installation Instructions Main runner distance 1200mm/1250mm Please ensure you have read the previous chapters in this manual as they contain information on the correct installation of the system. Perimeter trim As preparation before the installation, all perimeter features (walls, columns etc) should be marked with a guideline of the ceiling height (the height of the top edge of the perimeter trim). Perimeter trims should be installed using appropriate fixings and mitred at the corners (see page 10). Hangers The position of the top fixings can be taken from the reflected ceiling layout and their positions marked on the soffit. Additional hangers may be required depending upon: Main runner spacing Maxiumum edge distances (first and last hangers) Additional hangers that may be required to support services Main Runners Ensure that the hangers are the correct lenght for the installation. The hangers themselves should all be aligned in the same direction. After the main runners are installed, they need to be aligned and horizontally levelled. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 19/25 INSTALLATION INSTRUCTION 300 System C Installation advice Main runner centre‘s 1200/1250mm Long cross Tees The long cross tees can now be installed in complete rows, starting with areas 1 & 2 first. The cross tees have to be cut to fit at the perimeter. Care should be taken to ensure an adequate amount of cross tee is supported on the perimeter trim. 4 1 2 3 Short cross Tees The short cross tees are also installed in rows as well, starting with areas 1 & 2 first. The cross tees have to be cut to fit at the perimeter. Care should be taken to ensure an adequate amount of cross tee is supported on the perimeter trim. Please note: Please ensure that the main runners are aligned correctly and the grid construction is square. This needs to be done as early as possible and continually checked to reduce possible alignment work to a minimum. Not doing so can lead to substantial delays when the tiles are installed. This is especially important when VT edge tiles are being used. This also reduces the possibility of tile damage during future maintenance work. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 20/25 INSTALLATION INSTRUCTION 300 System C Installation advice Main runner centre‘s 1200/1250mm Ceiling tiles If the ceiling void is deep enough, at least 120mm (although 150mm is preferred) installation from below is possible without any problems. The tiles should be installed first in areas with hangers to avoid damage. The perimeter tiles can be cut with a standard hand held blade (Stanley knife or similar). Advice: When using suspension wires with wire hooks, there is a possibility of damage to the panels occurring during installation. Please observe the installation sequence opposite. Tile removal should be done in the same manner. Warning: Damage to tile possible 4.3 Main runner centres 600mm/625mm Installation of the 600mm/ 625mm system varies only slightly to the 1200mm/ 1250mm system Perimeter trim Perimeter trims should be installed as above. correct installation of the tile Hangers Due to the closer centre‘s of the main runners, additional hangers are required. Main runners Main runners are installed as above, but approximately twice the number of main runners are needed. Long cross tees Not required Short cross tees Identical, but they are installed between main runners. Ceiling Tiles Due to the larger number of hangers in the void, additional care is required when installing the tiles. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 21/25 INSTALLATION INSTRUCTION 300 System C 5. Special Design 5.1 Direct Fix For ceiling installations where a conventional installation is not possible, a direct suspension can offer a reduced installation height. This, however, can make removing or changing SK or VT edge tiles at a later time, difficult. Consideration should be given to using an SF edge tile which provides full accessibility. SAH L DAH Direct hanger Product DAH SAH L:Length 40mm 45mm H: Installation depth ca. 60mm ca. 80mm H A Sti Step by Step installation When using SK or VT edge tiles, installing the tiles from below is not possible. Instead the tiles are put into the grid system as it is being constructed. SF edge tiles can be installed from below and are easy to install. Installation The grid is set out according to the ceiling layout. The correct number of hangers need to be threaded onto the grid section and affixed to the soffit. The cross tees and tiles are then installed as the ceiling is built up. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 22/25 INSTALLATION INSTRUCTION 300 System C Special Design 5.2 Thermal insulation It is not recommended that insulation is supported on the suspended ceiling for the following reasons: •Following installation the ceiling void becomes inaccessible. Further access can cause damage to the ceiling tiles. •The grid structure must be laid out accordingly for additional loads to be added. •Loads supported directly on the ceiling tiles are not allowed. •The grid system, including ceiling tiles, does not create an airtight seal. •The installation of a vapour barrier would be required, although technically and practically this is not possible. Please see the following example for clarification. A suspended ceiling is installed under a hall ceiling with existing foam insulation. The insulation is placed directly on to the suspended ceiling which reduces the temperature in the ceiling void and the underside of the roof. As cold air holds much less water vapour than warm air, condensation forms in the ceiling void. A potential solution to this could be to use a vapour barrier, although due to the large number of hangers and subsequent penetrations that would be required this solution is not feasible. The structure and the thermal insulation should be chosen so that water vapour cannot reach the structure, or only a small amount, that won’t cause condensation. The picture below, shows a suitable construction with insulation and a vapour barrier (see manufacturers details for installation). The construction will need to provide fixing points for the suspended ceiling grid e.g. 4/6cm wood slats. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 23/25 INSTALLATION INSTRUCTION 300 System C Special Design 5.3 Angled Ceilings When installing a suspended ceiling on a slope, the following needs to be considered: Slope < 10 degrees: Main runners can be installed at 1200mm/ 1250mm centres Slope >10 degrees: Main runners have to be at 600mm/ 625mm centres Slopes > 30 degrees: Additional actions need to be taken Appropriate hangers must be used. Quick Hangers with hooks, rigid angles or prestraightened steel wire are acceptable. Hanger centre‘s should be according to the system data and the ceiling pitch. Ensure that the general installation guidelines for grid installation and additional loading are followed. 9 DN: Ceiling pitch 0° - 30° 9 Hanger centre‘s (see System-Construction page 2/3) GABLE WALL Perimeter trim at eaves The use of an additional timber batten adjusted to the relevant slope is recommended. The picture below shows several alternatives. Without the batten even a small slope will leave a visible gap between the tiles and the trim at the perimeter. The main runners and grid system have to be butt jointed tightly against the perimeter trim. APEX hanger Short cross tee Main runner EAVES Perimeter trim at gables As the main runners are installed down the slope the cross tees will be installed onto the perimeter trim going up the slope. This means the cross tees could slide down the slope. To prevent this, the cross tees need to be fixed using the wall connection angle shown in the picture. All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 24/25 INSTALLATION INSTRUCTION 300 System C 6. Documentation System C as fire protection Because of the special requirements for fire rated ceilings, please refer to the following documents. This is not a complete list. Please contact the AMF office for specific advice. WFRC. NO C102765 Fire Protection under Steel Beams WFRC. NO C117523 Fire Protection under Timber Joists WFRC. NO C102642 Fire Protection under Mezzanine Floors Programme Part 1 The Ceiling Systems Catalogue provides an overview of our classic mineral tile range and our special ranges: Fire Protection, Acoustic, Health & Hygiene, Sound, Light & E-tech and Material & Design. The programmes are available on request or can easily be downloaded at: www.amfceilings.co.uk Product Data Sheets If you require special information on one of our many products, information can be found on our website at any time. From the homepage, click on Products and then select the product required. www.amfceilings.co.uk Specifications Sample specifications can also be downloaded from the products pages of our website. For a tailored specification, or for more detailed product information, please contact your local AMF representative. www.amfceilings.co.uk All information provided is current technical data. All relevant test reports, assessments and installation guidelines are to be considered. All system details conform with current technology and are based on the use and compatibility of AMF products and system components used in both internal and external tests. AMF accepts no liability or responsibility for use of third party components, or for any variations to conditions stipulated in test data. We recommend not to mix production batches on jobs. 12/2010 25/25