ENV/JM/MONO(2010)

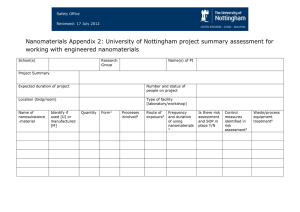

advertisement