Robust High Voltage Divider Resistors

advertisement

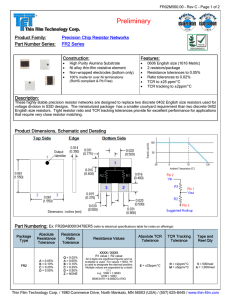

Robust High Voltage Divider Resistors RHVD Series Robust High Voltage Divider Resistors · Voltage ratingsVoltage up to 15kV Divider Resistors Robust High · Non-inductive design · Ratio tolerance down to 0.25% TCR tracking down to 25ppm/°C RHVD·Series · RHVDRobust SeriesDIL terminations for vibration performance · Custom design • Voltage ratings up to service 15kV available Voltage up to 15kV · RoHSratings compliant • • Non-inductive design • • • • • • Ratio Non-inductive design tolerance down to 0.25% • TCR Ratio tolerance down to 0.25% tracking down to 25ppm/°C • Robust TCR tracking down to 25ppm/°C DIL terminations for vibration performance • Custom Robustdesign DIL terminations for vibration performance service available Electrical Data • RoHS Custom design service available compliant • RoHS compliant RHVD08 Power rating at 70°C Electrical Data Limiting voltage in air dc or ac pk Electricalelement Data RHVD10 RHVD10A RHVD15 RHVD15A watts 0.5 0.75 1.0 1.5 2.0 kV 7.5 10 10 15 15 RHVD08 RHVD10 RHVD15 RHVD15A Resistance value ohms 10K – 1G 50KRHVD10A – 1G 100K – 1G watts 0.5 0.75 1.0 1.5 2.0 RHVD08 RHVD10 RHVD10A RHVD15 RHVD15A Power rating at 70°C Resistance tolerance % 1, 5 Limiting kV 7.50.5 100.75 101.0 151.5 152.0 watts Powerelement rating atvoltage 70°C in air dc or ac pk Ratio tolerance 0.25, 0.5, 1 Resistance value 1G% 100K – 1G Limiting element voltage in air dc or ac pk ohmskV 10K – 7.5 1050K – 1G 10 15 15 TCR (20°C ppm/°C 50, 100 Resistance tolerance % 1, 5 Resistance valueto 70°C) ohms 10K – 1G 50K – 1G 100K – 1G Ratio tolerance %% 0.25, 0.5, Resistance tolerance 1, 51 25, 50 Tracking TCR (20°C to 70°C) ppm/°C TCR (20°C to 70°C) 50, 1000.5, 1 ppm/°C % Ratio tolerance 0.25, Standard values E24 preferred for (R1 + R2) and R2 Tracking TCR to (20°C to 70°C) 25,50, 50100 TCR (20°C 70°C) ppm/°C ppm/°C Ambient temperature range °C -55 to +155 Standard values E24 preferred for 25, (R150 + R2) and R2 Tracking TCR (20°C to 70°C) ppm/°C Insulation ohms >10G Ambient temperature range at 500V -55 tofor +155 °C Standard valuesresistance E24 preferred (R1 + R2) and R2 Insulation at 500V ohms °C >10G Ambientresistance temperature range -55 to +155 Dielectric strength of insulation volts >1000 Dielectric strength of Insulation resistance at 500V ohms >10G volts >1000 Other resistance, tolerance and TCR values are available on request. insulation Dielectric strength of volts >1000 insulation Physical Physical Data Data All dimensions are in mm, weight in g All Physical dimensions areData in mm, weight in g All dimensions are in mm, weight inHSg H W P P2 P2 P3 P3 LL LL L P Type LW ±0.5 Type Max H Max ±0.5 SS ±0.5 ±0.25 ±0.5 ±0.25±0.5 ±0.5±0.75 ±0.75 ±0.5 L ±0.5W ±0.25P ±0.25P2 P3 LL Type Max ±0.5 ±0.5 9.17 ±0.5 9.17 ±0.25 ±0.25 ±0.5 25.4 22.86 5.088.72 8.72 ±0.75 RHVD08 RHVD08 25.4 22.86 5.08 RHVD10 38.1 35.56 7.62 8.72 RHVD08 25.4 9.17 9.17 9.17 22.86 RHVD10 38.1 35.56 5.08 7.62 8.72 8.72 RHVD10A 2 35.56 RHVD10 38.1 38.1 13.4 9.17 5 35.56 7.62 7.62 12.95 8.72 5.08 5 2 5.08 RHVD10A 38.1 13.4 35.56 7.62 12.95 RHVD15 RHVD10A 50.8 38.1 9.17 13.4 5 2 48.26 35.56 10.16 7.62 8.72 12.95 5.08 RHVD15A 50.8 15.94 48.26 10.16 15.45 RHVD15 50.8 50.8 9.17 9.17 48.26 RHVD15 48.26 10.16 10.16 8.72 8.72 RHVD15A 50.8 15.94 48.26 10.16 15.45 RHVD15A 50.8 15.94 48.26 10.16 15.45 Construction Termination conductors and ruthenium oxide resistive material are printed in a Construction L L 6 WtWt nom nom Wt nom 0.72 0.72 W R1 2 3 1 2 LL 3 6 6 o R1 5 R25 o o 2 o R1 1 P coated bronze leadframeterminations terminations are solder dipped SnAgCu and meet thephosphor following IECleadframe requirements: IEC 68.2.21 – Strength, SolderSolder coated phosphor bronze are solder dippedininSnAgCu and meet themeet following IEC IEC 68.2.21 –IEC Strength, IEC –115-1, Clause 4.17.3.2 – IECSnAgCu 115-1, Clause 4.17.3.2 – requirements: Solderability and the following IEC requirements: 68.2.21 Strength, Solderability IEC 115-1, Clause 4.17.3.2 – Solderability LL H 1.4 0.5 o o 1 o applied and terminals are then attached. Terminations Solder coated phosphor bronze leadframe terminations are solder dipped in Terminations Terminations R2 H o Construction non-inductive pattern onto and the surface of aoxide 96%resistive aluminamaterial substrate. screen-in a Termination conductors ruthenium areAprinted Termination and ruthenium resistive material are printedA inscreena non-inductive printed protection isconductors then onto applied terminals are then attached. non-inductive pattern the and surface ofoxide a 96% alumina substrate. onto the surface of a 96% alumina substrate. A screen-printed protection is then printedpattern protection is then applied and terminals are then attached. 0.25 4 R2 R1 1 1.4 0.5 0.25 4 5 W 0.99 0.72 0.99 1.42 0.99 1.42 1.31 1.42 1.99 1.31 1.31 1.99 1.99 5 6 o P3 P3 o 1 o o 6 1 4 o o 3 o 4 R2 2 3 P2 P 6 o 0.8mm hole sizes 0.8mm hole sizes o o 5 2 o P2 o o 5 2 o 4 o 3 o 4 3 General Note General Note electronics reserves the right to make changes in product specification without notice or liability. GeneralTTNote information is subject to TT changes electronics’ dataspecification and is considered accurate at or time of going to print. TT electronicsAllreserves the right to make in own product without notice liability. All information is subject to TT electronics’ own data and is considered accurate at time of going to print. TT electronics reserves the right to make changes in product specification without notice or liability. © TT electronics All information is subject to TTplc electronics’ own data and is considered accurate at time of going to print. © TT electronics plc © TT electronics plc www.bitechnologies.com www.irctt.com www.welwyn-tt.com www.bitechnologies.com www.irctt.com www.welwyn-tt.com www.bitechnologies.com www.irctt.com www.welwyn-tt.com 09. 13 08.13 Robust High Voltage Divider Resistors RHVD Series Marking Robust High Voltage Divider Resistors Type reference, TCR codes, resistance values, tolerance codes and date code are legend marked. The resistance value code conforms to IEC 62. Solvent Resistance The body protection and marking are resistant to all normal industrial cleaning solvents suitable for printed circuits. RHVD Series Performance Data Marking Type reference, resistance values and tolerances are legend marked. The resistance value code conforms to IEC 62. Maximum Solvent Resistance ΔR% suitable Loadbody at rated power: 1000 at 70°C <100M: for 0.25, ≥100M: 0.5 The protection and hours marking are resistant to all normal industrial cleaning solvents printed circuits. ΔR% Overload: 1.5 x rated power not exceeding LEV for 5 seconds 0.25 Performance Data Moisture resistance: MIL Std. 202, method 106 ΔR% Temperature rapid change: 5cycles -55 / 155°C Load at rated power: 1000 hours at 70°C Overload: x rated power not exceeding LEV for10 5 seconds Vibration: 1.5 MIL-Std-202G, method 204D, 12cycles, to 50Hz, 1.53mm/10g Moisture resistance: MIL Std. 202, method 106 Temperature rapid change: 5cycles -55 / 155°C Typical VCR (ppm/V) Type Vibration: MIL-Std-202G, method 204D, 12cycles, 10 to 50Hz, 1.53mm/10g RHVD08 Typical VCR (ppm/V) RHVD10 RHVD08 -0.50 RHVD10A RHVD10 -0.35 RHVD10A -0.25 RHVD15 RHVD15 -0.20 RHVD15A RHVD15A -0.15 ∆R% ∆R% ∆R% ∆R% ∆R% 0.25 Maximum ΔR% 0.25 <100M: 0.50.25 >100M 0.25 0.25 ΔR% 0.25 0.25 0.25 Typical 0.1 0.1 0.1 Typical 0.1 0.1 0.1 0.1 0.1 0.1 0.1 -0.50 Type -0.35 -0.25 -0.20 -0.15 Application Notes Due to the high voltage, which can appear between the terminations and any adjacent metal part, resistors should be mounted at an adequate Application Notes distance from other conductors. Due to the high voltage, which can appear between the terminations and in any should becompound mounted to at an For some ultra-high voltage applications it is required to immerse the components oil adjacent or SF6 gasmetal or potpart, themresistors in void-free silicone adequate distance from other conductors. reduce corona or surface tracking. The printed protection is suitable for these applications. Fordivider some consists ultra-high voltage it is Rrequired to immerse the components oil orby SFRatio The of high valueapplications R1 and low value . The voltage division ratio of the divider in is given = or R2 pot : (R1 them + R2) in void-free silicone 6 gas 2 compound to reduce corona or surface tracking. The printed protection is suitable for these applications. The divider consists of high value R1 and low value R2. The voltage division ratio of the divider is given by Ratio = R2 / (R1 + R2). Ordering Procedure Ordering Procedure Example: RHVD15 for a voltage ratio of 1:1000, with R1 = 99.9 megohms and R2 = 100 kilohms (total R1 + R2 = 100 megohms) at 50ppm/°C Example: RHVD15 for a voltage ratio of 1:1000, with R1 = 99.9 megohms and R2 = 100 kilohms (total R1 + R2 = 100 megohms) at absolute andabsolute 25ppm/°Cand tracking TCR, 1% absolute and 0.5% ratio tolerance. 50ppm/°C 25ppm/°C tracking TCR, 1% absolute and 0.5% ratio tolerance. R 1 1 1 Type R= RHVD 5 2 C D - 1 3 2 0 0 M / 1 0 4 3 0 5 ZC 10 ZD 10A CD 15 15A 100ppm absolute and 50ppm tracking 100ppm absolute and 25ppm tracking 50ppm absolute and 25ppm tracking F D 6 4 Size TCR (Absolute and Tracking) Value (R1 + R2) 08 K 5 6 Tolerance (Absolute and Ratio) Value (R2) K = kilohms, M = megohms, G = gigohms JF 5% absolute and 1% ratio FD 1% absolute and 0.5% ratio FC 1% absolute and 0.25% ratio General Note General Note TT electronics reserves the right to make changes in product specification without notice or liability. Allelectronics information is subject to TTtoelectronics’ ownindata and specification is consideredwithout accurate at time of going to print. TT reserves the right make changes product notice or liability. All information is subject to TT electronics’ own data and is considered accurate at time of going to print. © TT electronics plc © TT electronics plc www.bitechnologies.com www.irctt.com www.welwyn-tt.com www.bitechnologies.com www.irctt.com www.welwyn-tt.com 08.13 09. 13