VA - VB - VD

advertisement

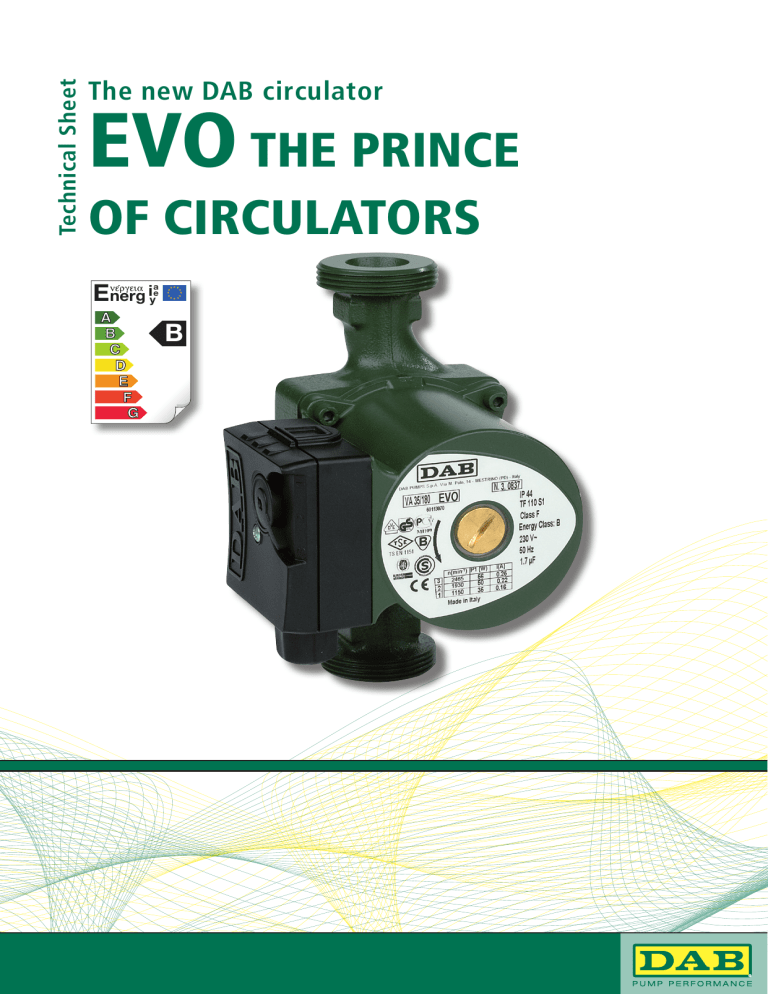

Technical Sheet The new DAB circulator EVO THE PRINCE OF CIRCULATORS Energ iy a e B VA - VB - VD Applications Pump for circulating hot water in centralised domestic heating and air-conditioning systems of the closed and pressurised or open tank type. Construction features Single body comprising a technopolymer hydraulic unit and a wet rotor motor. Bronze air separator. Die-cast aluminium motor casing. Technopolymer impeller. Tempered stainless steel driving shaft mounted on graphite bearings lubricated by the pumped liquid. Stainless steel protective rotor sleeve, stator sleeve and closing flange. Ceramic thrust brushings, E.P.D.M. „O“ rings and brass air outlet cap. Two-pole asynchronous motor with squirrel cage rotor designed for three-speed operation by means of a special switch on the terminal board which automatically adapts performance in relation to system requirements. Motor self-protected for resistance. No overload protection required. Protection level: IP 44 Insulation class: F Cable grommet: PG 11 Installation: with horizontal motor shaft. Working voltage: single-phase 230 V / 50 Hz Special versions on request.: - alternative voltages and/or frequencies technical data Operating range: Liquid temperature range: Pumped fluid: Max. working pressure: Installation: VA - VB - VD: from 0,5 a 3,6 m3/h with pressure head of up to 6 m. VA - VB - VD: from -10°C to +110°C clean, free of solid contaminants and mineral oils, non-viscous, chemically neutral, close to the properties of water (max glycol 30%). VA - VB - VD 10 bar (1000 kPa) with horizontal motor shaft. DAB PUMPS reserve the right to make modifications without prior notice VA - VB - VD Hydraulic data VA 25 VA - VB - 35 0 2 0 P kPa 4 6 2 8 4 10 6 12 8 14 10 12 Hm Q US gpm 0 Q IMP gpm H Ft 0 P kPa Energ iy a e 25 20 2.5 45 B 8 40 35 2.0 6 15 30 1.5 4 10 5 0 1.0 2 0.5 0 0 0 0.5 1.0 1.5 0.4 0.2 0 10 2.0 2.5 20 30 0 Q m3 /h Q l/sec 3.0 0.6 0.8 40 50 2 0 P kPa 55 50 45 4 2 8 10 6 12 8 14 10 16 12 14 Hm Energ iy a e 5.0 * 3.0 10 2.5 1.0 0.5 0 0 10 8 20 2.0 15 1.5 10 1.0 5 0.5 0 0 45 40 35 0 1.0 10 4 2 0 0 0.5 1.0 1.5 0.4 0.2 10 2.0 2.5 0.6 20 3.0 0 Q m3 /h Q l/sec 50 Q l/min 0.8 30 40 1.5 0.4 20 2.0 2.5 0.6 30 3.0 0.8 40 50 2 4 6 2 8 4 10 6 12 8 14 10 16 12 Q US gpm 14 Hm Q IMP gpm H Ft 6.0 20 Energ iy a e 5.5 5.0 18 C 4.5 16 14 4.0 12 3.5 3.0 10 8 25 2.5 8 6 20 2.0 15 1.5 10 1.0 5 0.5 0 0 2 0.2 6 30 4 0.5 12 3.5 2.5 50 12 0 0 14 3.0 55 14 30 5 Q IMP gpm H Ft 25 P kPa 60 16 3.5 10 Q US gpm 12 B 0 35 1.5 14 4.0 0 4.0 2.0 12 10 a e Q IMP gpm 18 B 4.5 15 10 8 Energ iy 0 H Ft 5.5 20 8 6 4.5 Q US gpm 40 25 6 4 VA - VB - VD 65 6 4 4 2 Hm Q l/min VA - VB - VD 55 0 2 3.5 1.0 0 Q m3 /h Q l/sec 60 Q l/min 6 4 2 0 0 0 0.5 1.0 1.5 0.4 0.2 10 20 2.0 2.5 3.0 0.6 30 0.8 40 50 3.5 1.0 0 Q m3 /h Q l/sec 60 Q l/min ELECTRICAL DATA ELECTRICAL DATA MODEL CENTRE DISTANCE mm SPEED 1 x 230 V ~ 3 2 1 2655 2380 1680 43 38 31 1 x 230 V ~ 3 2 1 2465 1930 1150 1 x 230 V ~ 3 2 1 1 x 230 V ~ VA 25/130 VA 25/180 VA 25/180 X VA 35/130 VA 35/130 1/2” VA 35/180 VA 35/180 X VA 55/130 VA 55/130 1/2” VA 55/180 VA 55/180 X VA 65/130 VA 65/130 1/2” VA 65/180 VA 65/180 X 130 VB 35/120 120 1 x 230 V ~ VB 55/120 120 1 x 230 V ~ VB 65/120 120 1 x 230 V ~ VD 55/220.32 220 1 x 230 V ~ VD 65/220.32 220 1 x 230 V ~ 180 In A VOLTAGE. 50 Hz 130 180 130 180 130 180 DAB PUMPS reserve the right to make modifications without prior notice r.p.m. UNIONS ON REQUEST P1 MAX KW CAPACITOR STANDARD SPECIAL 1” F 1” F 1¼” 1” F 1” F 1¼“ 1” F 1” F 1¼” 1” F 1” F 1¼” ¾” F - 1 ¼” M ¾”F1¼”M µF Vc 0,19 0,17 0,15 1,5 450 56 50 35 0,25 0,22 0,16 1,7 450 2400 1600 930 70 58 36 0,3 0,26 0,17 1,7 450 3 2 1 2310 1532 880 78 59 37 0,34 0,26 0,17 2 450 3 2 1 3 2 1 3 2 1 3 2 1 3 2 1 2465 1930 1150 2400 1600 930 2310 1532 880 2400 1600 930 2310 1532 880 56 50 35 70 58 36 78 59 37 70 58 36 78 59 37 0,25 0,22 0,16 0,3 0,26 0,17 0,34 0,26 0,17 0,3 0,26 0,17 0,34 0,26 0,17 1,7 450 DN 25 DN 20 – DN 32 1,7 450 DN 25 DN 20 – DN 32 2 450 DN 25 DN 20 – DN 32 1,7 450 DN 32/PN 6/PN 10 - 2 450 DN 32/PN 6/PN 10 - MINIMUM HEAD PRESSURE ¾”F1¼”M ¾”F1¼”M ¾”F1¼”M ¾”F1¼”M ¾”F1¼”M ¾”F1¼”M t° +90°C m.t. 1,5 * VD 55 = C class D H2 D2 DIMENSIONS AND WEIGHTS H H VA - VB - VD VA VB B2 B B1 B B2 B1 H D2 L2 H2 L H2 L1 L2 L L1 H H1 H D F B2 B B1 D1 D4 L D D2 L1 H1 H L2 L2 H2 D5 L L1 VD B1 MODEL VB 35/120 VB 55/120 VB 65/120 packaging dimension Q.TY WEIGHT X Kg PALLET L L1 L2 B B1 B2 H H1 H2 F L B H VOLUME m3 130 93 59 102,5 76,5 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 180 93 59 102,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 180 93 59 102,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 130 93 59 102,5 76,5 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 130 93 59 102,5 76,5 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 180 93 59 102,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 180 93 59 102,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 130 93 59 102,5 76,5 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 130 93 59 102,5 76,5 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 180 93 59 102,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 180 93 59 102,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 130 93 59 102,5 76,5 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 130 93 59 102,5 76,5 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 180 93 59 102,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 180 93 59 102,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 model VA 25/130 VA 25/180 VA 25/180 X VA 35/130 VA 35/130 1/2” VA 35/180 VA 35/180 X VA 55/130 VA 55/130 1/2” VA 55/180 VA 55/180 X VA 65/130 VA 65/130 1/2” VA 65/180 VA 65/180 X B2 B packaging dimension VOLUME m3 L B H Q.TY WEIGHT X Kg PALLET L L1 L2 B B1 B2 H H1 H2 D2 D1 I 120 98 60 104 78 26 124 75 49 25 M10 78 135 135 150 0,0027 240 2,7 120 98 60 104 78 26 124 75 49 25 M10 80 135 135 150 0,0027 240 2,7 120 98 60 104 78 26 124 75 49 26 M10 80 135 135 150 0,0027 240 2,7 D1 D5 pack. dimension Q.TY WEIGHT X Kg PALLET L B H VOLUME m3 VD 55/220.32 220 91,5 128,5 150 50 100 140 90 100 70 32 14 18 230 115 115 160 253 238 0,0096 84 8,2 VD 65/220.32 220 91,5 128,5 150 50 100 140 90 100 70 31 14 18 230 115 115 160 253 238 0,0096 84 8,2 MODEL L L1 L2 B B1 B2 D DAB PUMPS reserve the right to make modifications without prior notice PN6 PN10 D2 D4 PN6 PN10 H H1 H2 VS Applications wet rotor is self-protected for resistance. No overload Pump for hot water circulation in hot water domestic systems of the closed and pressurised or open tank type. protection required. Construction features Insulation class: F Single body formed of the bronze hydraulic unit. Diecast aluminium motor casing. Technopolymer impeller. Ceramic driving shaft mounted on graphite brushings lubricated by the pumped liquid itself. Stainless steel protective rotor sleeve, stator sleeve and closing flange. Ceramic thrust bearing, E.P.D.M. “O” rings. The two-pole or four-pole asynchronous motor with Cable grommet: PG 11 Protection level: IP 44 Installation: with horizontal motor shaft. Working voltage: single-phase 230 V / 50 Hz Special versions on request.: - alternative voltages and/or frequencies technical data Operating range: Liquid temperature range: from 0,6 a 3,7 m3/h with pressure head of up to 6 m. from -10°C to +85°C for sanitary use from -10°C to +110°C for others use Pumped fluid: clean, free of solid contaminants and mineral oils, non-viscous, chemically neutral, close to the properties of water (max glycol 30%). Max. working pressure: 10 bar (1000 kPa) Installation with horizontal motor shaft DAB PUMPS reserve the right to make modifications without prior notice VS Hydraulic data VS 8 VS 16 0 2 0 P kPa 8 7 6 5 4 6 2 8 4 10 6 8 Hm Energ iy Q US gpm 0 Q IMP gpm H Ft 0 P kPa 18 a e 0.8 2.5 B 0.7 16 14 2.0 0.6 12 0.5 1.5 4 0.4 0.3 2 0.2 1 0.1 1.0 0 0 0.3 0.6 0.9 1.2 1.5 0.4 0.2 0 10 VS 35 0 2 0 1.8 20 4 6 2 30 8 4 Q m3 /h Q l/sec 2.1 0.6 10 6 12 8 14 14 10 Q US gpm 12 Q IMP gpm H Ft 6.0 a e 5.5 B 5.0 1.4 4.5 1.2 4.0 3.5 8 0.8 6 0.6 4 0.4 10 1.5 0 0 P kPa 60 Energ iy a e 0.3 0.6 16 0.9 1.2 1.5 0.4 0.2 10 2 0 1.8 20 4 2 2.4 8 40 10 6 2.7 12 8 3.0 Q m3 /h Q l/sec 50 Q l/min 0.8 30 6 4 2.1 0.6 14 10 16 18 12 14 Hm B 50 14 a e 3.0 10 2.5 8 40 2.0 C 20 16 14 4.0 12 3.5 6 Q IMP gpm H Ft 18 5.0 4.5 12 Q US gpm 20 Energ iy 6.0 5.5 4.0 3.0 10 2.5 8 2.0 6 1.5 4 1.0 2.0 0 12 Q IMP gpm H Ft Hm 5.0 2.5 VS 65 1.5 10 12 1.6 1.0 30 20 10 8 Energ iy 0 Q US gpm 3.5 30 8 6 1.8 Q l/min 4.5 40 6 4 Hm 10 0.5 50 4 2 3.0 3 P kPa 2 0 0 0.3 0.6 0.9 1.2 0.2 0 10 1.5 0.4 20 1.8 2.1 0.6 30 2.4 2.7 3.0 Q m3 /h Q l/sec 50 Q l/min 0.8 40 10 4 1.0 0 0 0.3 0 0.6 0.9 0.2 1.2 10 20 1.5 0.4 1.8 2.1 0.6 2.4 30 2.7 40 3.0 0.8 3.3 50 3.6 1.0 3.9 60 Q m3 /h Q l/sec Q l/min ELECTRICAL DATA VS 8/150 VS 16/150 VS 35/150 VS 65/150 SPEED 150 1 x 230 V ~ 3 150 1 x 230 V ~ 3 150 1 x 230 V ~ 150 1 x 230 V ~ In A 1340 22 0,14 2784 41 0,19 3 2470 55 3 2317 77 r.p.m. DIMENSIONS AND MINIMUM HEAD PRESSURE CAPACITOR STANDARD H VOLTAGE. 50 Hz P1 MAX KW µF Vc 1,5 450 1,5 450 0,24 1,7 450 0,34 2 450 H2 MODEL UNIONS ON REQUEST H1 ELECTRICAL DATA CENTRE DISTANCE mm SPECIAL Brass 1/2” F - 3/4” F - 1” F Copper d22 e d28 t° +90°C m.t. 1,5 B B1 B2 H2 L2 L L1 H H1 WEIGHTS F Q.TY WEIGHT X Kg PALLET L1 L2 B B1 B2 H H1 H2 FB2 L B H VOLUME m3 150 98 60 104 78 26 124 75 49 11/2” G 134 188 150 0,0038 180 2,6 150 98 60 104 78 26 124 75 49 11/2” G 134 188 150 0,0038 180 2,6 150 98 60 104 78 26 124 75 49 11/2” G 134 188 150 0,0038 180 2,6 150 98 60 104 78 26 124 75 49 11/2” G 134 188 150 0,0038 180 2,6 L1 B1 L2 VS 8/150 VS 16/150 VS 35/150 VS 65/150 B packaging dimension L L MODEL DAB PUMPS reserve the right to make modifications without prior notice F VSA G ATIN CO SIS FACE LIED SUR APP PHORE O S CES ELECTR PRO BY Applications Pump for circulation of fluid media in solar panel powered heating systems. VSA wet rotor circulators can function perfectly also with high glycol concentrations (up to 60%). Construction features Monobloc body composed of hydraulic section in cast iron and wet rotor motor. Special electrophoresis coating of the pump body to ensure resistance to glycol attack. Motor casing in diecast aluminium. Rotor in engineering polymer, motor shaft in hardened stainless steel held in graphite bearings lubricated by the pumping medium. Rotor protective jacket, stator jacket, and closing flange in stainless steel. Ceramic thrust ring, ethylene propylene seals and brass air breather plug. Two-pole asynchronous motor with squirrel cage rotor designed to run at three alternative speeds on the basis of the setting of a selector on the terminal board in order to adapt circulator operation to the characteristics of the system. Protection level:IP 44 Insulation class: F Working voltage: single-phase 230 V / 50 Hz Special versions on request.: - alternative voltages and/or frequencies - OEM multipack version technical data Operating range: from 0 a 3,6 m3/h with pressure head of up to 6 m. Liquid temperature range: from -10°C to +110°C (TF110) All models are designed to withstand temperature peaks of up to 140°C Pumped fluid: clean, free of solid contaminants and mineral oils, non-viscous, chemically neutral, close to the properties of water (max glycol 60%). Max. working pressure: 10 bar (1000 kPa) Installation with horizontal motor shaft DAB PUMPS reserve the right to make modifications without prior notice VSA Hydraulic data VSA 25 VSA 35 0 2 0 P kPa 4 6 2 8 4 10 6 12 8 14 10 12 Q US gpm 0 Q IMP gpm 0 Hm H Ft P kPa Energ iy a e 25 20 2.5 45 B 8 40 35 2.0 6 15 30 1.5 4 10 5 0 1.0 2 0.5 0 0 0 0.5 1.0 1.5 0.4 0.2 0 10 2.0 2.5 20 30 0 Q m3 /h Q l/sec 3.0 0.6 0.8 40 50 0 P kPa 55 50 45 4 2 6 4 8 10 6 12 8 14 10 16 12 14 Hm Energ iy C 30 3.0 10 2.5 1.0 0.5 0 0 12 3.5 10 2.5 8 20 2.0 15 1.5 10 1.0 5 0.5 0 0 50 45 40 35 6 4 2 0 0 0.5 1.0 1.5 0.4 0.2 10 2.0 2.5 0.6 20 30 3.0 0 Q m3 /h Q l/sec 50 Q l/min 0.8 40 1.0 1.5 0.4 0.2 10 20 2.0 2.5 0.6 30 3.0 0.8 40 50 4 6 2 8 4 10 6 12 8 14 10 16 12 Q US gpm 14 Hm Q IMP gpm H Ft 6.0 20 Energ iy a e 5.5 5.0 18 C 4.5 16 14 4.0 12 3.5 3.0 10 8 25 2.5 8 6 20 2.0 15 1.5 10 1.0 5 0.5 0 0 2 0.5 2 30 4 0 14 3.0 55 12 0 0 Q IMP gpm H Ft 25 P kPa 60 14 3.5 5 Q US gpm 12 B 0 35 10 14 4.0 0 4.0 1.5 12 10 a e Q IMP gpm 16 4.5 2.0 10 8 Energ iy Q US gpm 18 a e 5.0 15 8 6 4.5 0 H Ft 5.5 20 6 4 VSA 65 2 40 25 4 2 Hm Q l/min VSA 55 0 2 3.5 1.0 0 Q m3 /h Q l/sec 60 Q l/min 6 4 2 0 0 0 0.5 1.0 1.5 0.4 0.2 10 2.0 2.5 0.6 20 30 3.0 0.8 40 50 3.5 1.0 0 Q m3 /h Q l/sec 60 Q l/min ELECTRICAL DATA ELECTRICAL DATA MODEL VSA 25/130 VSA 25/180 VSA 25/180 X VSA 35/130 VSA 35/130 1/2” VSA 35/180 VSA 35/180 X VSA 55/130 VSA 55/130 1/2” VSA 55/180 VSA 55/180 X VSA 65/130 VSA 65/130 1/2” VSA 65/180 VSA 65/180 X CENTRE DISTANCE mm VOLTAGE. 50 Hz SPEED 1 x 230 V ~ 3 2 1 130 180 2655 2380 1680 P1 MAX KW In A 43 38 31 0,19 0,17 0,15 CAPACITOR µF 1,5 STANDARD SPECIAL 1” F ¾” F - 1 ¼” M 1” F ¾”F1¼”M Vc 450 1 x 230 V ~ 180 3 2 1 2465 1930 1150 56 50 35 0,25 0,22 0,16 1,7 450 ¾”F1¼”M 1” F ¾”F1¼”M 1¼“ 1” F 130 1 x 230 V ~ 180 3 2 1 2400 1600 930 70 58 36 0,3 0,26 0,17 1,7 450 t° +90°C m.t. 1,5 ¾”F1¼”M 1” F ¾”F1¼”M 1¼” 1” F 130 1 x 230 V ~ 3 2 1 MINIMUM HEAD PRESSURE 1¼” 1” F 130 180 r.p.m. UNIONS ON REQUEST 2310 1532 880 78 59 37 0,34 0,26 0,17 2 450 ¾”F1¼”M 1” F 1¼” ¾”F1¼”M VSA DIMENSIONS AND WEIGHTS B B1 H2 L2 L L1 H H1 B2 F MODEL packaging dimension Q.TY WEIGHT X Kg PALLET L B H VOLUME m3 48 135 135 150 0,0027 240 2,5 50,5 48 130 190 150 0,0037 180 2,6 50,5 48 130 190 150 0,0037 180 2,6 75 50,5 48 135 135 150 0,0027 240 2,5 75 50,5 48 135 135 150 0,0027 240 2,5 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 102,5 76,5 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 59 102,5 76,5 26 125,5 75 50,5 48 135 135 150 0,0027 240 2,5 59 102,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 59 102,5 76,5 26 125,5 75 50,5 48 130 190 150 0,0037 180 2,6 L L1 L2 B B1 B2 H H1 H2 F VSA 25/130 130 93 59 102,5 76,5 26 125,5 75 50,5 VSA 25/180 180 93 59 102,5 76,5 26 125,5 75 VSA 25/180 X 180 93 59 102,5 76,5 26 125,5 75 VSA 35/130 130 93 59 102,5 76,5 26 125,5 VSA 35/130 1/2” 130 93 59 102,5 76,5 26 125,5 VSA 35/180 180 93 59 102,5 76,5 26 VSA 35/180 X 180 93 59 102,5 76,5 26 VSA 55/130 130 93 59 102,5 76,5 VSA 55/130 1/2” 130 93 59 102,5 76,5 VSA 55/180 180 93 59 102,5 VSA 55/180 X 180 93 59 102,5 VSA 65/130 130 93 59 VSA 65/130 1/2” 130 93 VSA 65/180 180 93 VSA 65/180 X 180 93 DAB PUMPS LTD. Unit 4, Stortford Hall Industrial Park Dunmow Road, Bishops Stortford, Herts CM23 5GZ - UK Tel. +44 1279 652 776 Fax +44 1279 657 727 DAB PUMPS B.V. Albert Einsteinweg, 4 5151 DL Drunen - Nederland Tel. +31 416 387280 Fax +31 416 387299 info.nl@dabpumps.com DAB PUMPS B.V. Brusselstraat 150 B-1702 Groot-Bijgaarden - Belgium Tel. +32 2 4668353 Fax +32 2 4669218 DAB PUMPEN DEUTSCHLAND GmbH Tackweg 11 D - 47918 Tönisvorst - Germany Tel. +49 2151 82136-0 Fax +49 2151 82136-36 Pumps America, Inc. DAB PumpS Division 3226 Benchmark Drive Ladson, SC 29456 USA Ph. 1-843-824-6332 Toll Free 1-866-896-4DAB (4322) Fax 1-843-797-3366 DAB PUMPS IBERICA S.L. Parque Empresarial San Fernando Edificio Italia Planta 1ª 28830 - San Fernando De Henares - Madrid Spain Ph. +34 91 6569545 Fax +34 91 6569676 12/2008 60 116 995 DAB PUMPS RUSSIA 127247 Dmitovskoe sh., 100 bld. 3 Moscow, Russia Te : +7 095 485-1679 Via Marco Polo, 14 - Mestrino (PD) Italy - Phone +39.049.9048811 - Fax +39.049.9048847 Sales Export dept: Ph: +39-049-9048895-96-97 - Fax +39-049-9048900 Customer Technical Assistance: Ph. +39-049-9048911 - Fax +39-049-9048920 www.dabpumps.com