Home LED Light Control System with Automatic Brightness Tuning

advertisement

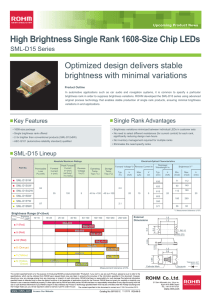

The 1st IEEE Global Conference on Consumer Electronics 2012 Home LED Light Control System with Automatic Brightness Tuning for The Difference in Luminous Decay Chi-Huang Hung, Ying-Wen Bai*, Wen-Chung Chang*, Ren-Yi Tsai* Graduate Institute of Applied Science and Engineering, Fu Jen Catholic University, New Taipei City, Taiwan, R.O.C. Department of Information Technology, LEE-MING Institute of Technology, Taiwan, R.O.C. Department of Electrical Engineering*, Fu Jen Catholic University, New Taipei City, Taiwan, R.O.C. 497598042@mail.fju.edu.tw, bai@ee.fju.edu.tw, 498505250@mail.fju.edu.tw, 499216076@mail.fju.edu.tw According to some test reports the junction temperature rises when the driven current of the LED is overloaded [6]. In this case the illumination decays more. Other research points out that when the junction temperature increases, the luminous efficiency drops. From measurements we learn that each LED tube may show a different level of luminous decay when it receives power. This difference in decaying depends on both the driven current and the interval of driving. Abstract—In this paper we present a design at the software and hardware modules of an embedded board with a sensor and an interface circuit both to control home LED lighting appliances and to avoid their difference in brightness caused by luminous decay. Our design is divided into three parts: an automatically adjusted LED driver, environment illumination detection and a wireless remote control unit. Keywords- Luminous decay, Wireless control unit, Ambient light sensor I. In the datasheet the lifetime of an LED is claimed to be up to 50,000 hours, but the lifetime is needed to spend so much time to measure illumination. Many experiments mostly use high driven current or a high temperature environment to measure illumination. In this paper we use varied amounts of current for the decrepitude test, so we will know the different brightness with different driven current for one day. In Figure 1, we see that if we increase the LED drive current the relative brightness increases, if we change the standard drive current from 30mA to 35mA, 40mA, 45mA or 60mA and use same equipment. The LED’s brightness slightly decreases after one day. We learn that from the blue line (60mA) the more than the critical current; the faster the decrease of its brightness. INTRODUCTION Some reports use a personal computer as a console and by means of the wireless IEEE 802.15.4 BASE control the digital addressable lighting interface (DALI) home lighting system. This home control design integrates both wired and wireless communication to achieve lighting control in the home and almost anywhere, but some countries in Asia find the DALI inconvenient [1]. Recently, in order to save energy, the majority of outdoor neon signs have been replaced by highbrightness LED billboards. As our design saves energy and is digitally control, we replace most of the interior lighting with LED arrays [2]. People often need home lighting control in their lives. These individuals can easily find relevant products which often use different methods to reach their goal. The control media include wire or infrared or radio frequency, and one research report has pointed out how to control the lights in a home remotely through either power line control (PLC) or the Internet [3]. With the traditional LED lighting appliance the brightness begins to decline after long use. We call this condition luminous decay [4]. There are two important factors that cause this decay: quality and the specific driven current. The first factor is a LED quality problem, especially if the manufacturer chooses either a poor quality LED die or a poor heat dissipation of the die [5]. The second is in the standarddriven current. When the LED has been used as a constant current source, although some products are designed to use voltage-driven current, its operation characteristics will drift. Some LEDs become brighter because the driven current is greater than the rated current. So after an LED has been used for some time, the LED shows a difference of luminous decay. 978-1-4673-1501-2/12/$31.00 ©2012 IEEE Figure 1. Relationship of time and brightness with different driven currents In this paper we assume that manufacturers are using LED dies of a certain above average quality; therefore, our design focuses on automatically adjusting the driven current to avoid any difference in luminous decay, by designing a software module, a sensor and an interface circuit of either the 261 embedded board or the smartphone to control the brightness of a LED lighting appliance. II. not generate an excessive amount of heat and does not cause the LED either to work too long or to burn In operation, assuming that the quality of the LEDs is good enough, we can focus on the LED driven current. From our experiment we have concluded that to avoid the illuminate decay we have to adjust the LED driven current from regular to 90% of the safe operating area. There are two advantages of reducing the driven current. First, a 90% driven current lets the LED operation cause the illuminate decay. Although the brightness will be less, this may not be perceived by the human eye. Second, any LED used for some time loses brightness. If the increased driven current of the LED continues to serve the operating area, the brightness will be readjusted to obtain the uniform brightness. THE ARCHITECTURE OF THE HOME LED LIGHT CONTROL SYSTEM The system hardware architecture, as shown in Fig. 2, is divided into several parts: the LED light source, the LED driver, the detection of environment illumination, the detection of LED brightness, the micro controller unit, the communication unit and the embedded remote controller. We use an SMT and a low power white light LED as the light source because then not only will the brightness fit our requirements, but there will also be low heat dissipation. The LED drivers have an adjustable constant current source circuit which can both accept the PWM signal input and change the brightness automatically. The detection of the LED brightness is carried out by measuring the LED intensity and inputting the resulting intensity through an analog-to-digital converter to transfer this intensity as a digital brightness signal feedback to the MCU to determine the amount of luminous decay. III. THE HARDWARE OF THE HOME LED LIGHT CONTROL SYSTEM In our design we divide the lighting control into four parts: LED tube, MCU, wireless module and the embedded remote controller, shown in Fig. 4. Every LED tube includes an LED array, an LED driver, illumination detectors and a DAC which operate together. The LED tube with a separate control unit is designed to reduce costs, because each control unit does not have to control an LED tube, as one unit can control up to four LED tubes and carry out the respective control and detection of different brightness. Figure 2. Block diagram of LED light control system The detection of the environment illumination which is affected by the light near our device reduces the effect of ambient illumination. Finally, the communication unit receives the control command from either the embedded remote controller or a smartphone. We include two ambient light sensors (ALS) to detect the inside and the outside brightness of the LED tube, as shown in Fig. 3 [5]. We dig a small window to facilitate the measurement of the outside environment brightness of LED tube, and place the other ALS inside the tube. With a black mask we isolate the two sensors to avoid mutual interference. For readability the mask location is only present in Fig. 3 as a dotted line. Figure 4. Diagram of lighting control Fig. 5 shows the LED driver circuit, which uses DC power to supply all circuits and uses an adjustable constant current integrated circuit to modify the output current to the LED module and the L1. The U1 can use a pin DIM to receive the PWM brightness control signal to adjust the brightness. Figure 3. ALS position in the LED tube Figure 5. LED driver circuit To reduce the effect of luminous decay we have limited the current of the LED driver output between upper and lower bounds, which correspond to the maximum and minimum brightness values. In this current operating state the LED does Fig. 6 shows the circuit when using the ambient light sensor (ALS) to detect the brightness [8], [9]. We take two ALS to detect both the LED brightness and the outside environment illumination through a two-channel ADC with a serial output 262 that transforms an analog brightness signal to a digital serial signal. The MCU calculates those signals and transfers them to different duty cycles of the PWM to provide the feedback process. When the LED brightness decays, as the ALS provides a smaller current through R2, resulting in a smaller voltage signal, therefore the MCU increases the PWM duty cycle of the output pulse, thus increasing the LED driver’s average current output with the increase in the LED brightness. Figure 7. User interface of the control panel When we choose the automatic mode, we hope to automatically adjust each LED lamp in a tube to the same brightness. Previously the LED lamps only changed their brightness one by one. When a LED tube has been working for a long time, the brightness of each one of its LED lamps develops a minor difference from the others. A brightness sensor is needed to detect this difference and to notify the controller to fine-tune the brightness. Fig. 6 (b) shows the result after the change from the automatic mode to the finetuning of every LED lamp. Figure 6. LED brightness detection circuit and detection of environment illumination IV. Fig. 8 shows the flowchart which has an automatic mode (Auto Mode) so that the system first reads the brightness of each lamp and then compares its brightness with that of the other lamps. If the brightness of the other lamps is greater than that of the first, the system decreases the brightness of the first lamp in order to reduce the current of the drive circuit output; respectively it increases its brightness to increase the current of the output current drive. The design prevents the LED from reaching maximum brightness, thus avoiding the overdrive region. When the adjustments have been completed, the system leaves the Auto Mode. THE SOFTWARE IN THE EMBEDDED REMOTE SYSTEM Generally people use the LED driver shown in Fig. 3 which works on on/off, with the LED work current locked on 280mA. One can also add a dimming circuit controlled through the DIM pin. In our design we add a feedback signal from the ALS which lets the user know the actual brightness of the environment. The calculation by the MCU sends a more accurate control PWM pulse than the normal ten-step brightness control signal. Our design reaches the goal of automatically adjusting the LED brightness to that of all other LEDs. We assume a maximum current of the LED of 90% of the normal drive, around 252mA. The other 10% are for the use of a buffer that can easily increase or decrease the LED driven current in order to fine-tune the brightness [10], [11]. Figure 8. Flowchart in Auto Mode The power-saving mode is designed for daylight or when Fig. 7 shows the panel screen of the embedded remote control. As we assume the maximum driver current of the LED lamp to be 280mA and the normal working current to be 90% of the assumed current, we use different colors to represent the difference in brightness in Fig. 7(a). We assume that there are eight controlled LED lamps, each with a different brightness, so that there will be eight different degrees of lighting on the screen giving both the brightness, the color and the percentage aspects of the brightness in real time. There are three buttons representing three different functions: automatic mode, power saving mode and exiting the control screen. the demand for brightness is not high. Entering this mode, the drive circuit reduces the current to 20% of the original brightness in order to save power. We have two control choices of the LED brightness: manual and automatic. The manual control screen is shown in Fig. 7 (b). It is just like a normal control where the user can type in what brightness he wants. One can also use a slide bar to change the brightness, which will change the color of the symbol at the same time. One enters this manual mode by just double-touching the LED symbol on Fig. 7(a). V. IMPLEMENTATION RESULTS As our design uses a stable output current, a very accurate detection of the brightness level is achieved. d. Controlling the output duty cycle of the PWM pulse achieves the fine-tuning function that adjusts the brightness of each LED light source closer to the user’s requirements. Fig. 9 shows the use of the feedback control of the microprocessor with both the brightness control circuit and the LED driver board. We can 263 put those printed circuit boards into the tube. Without the feedback circuit the system would only adjust to a lower accuracy of the brightness and only on a scale of 10. The difference shown in Fig. 9 is 80% (increase) and 20% (decrease) of the brightness. the operation mode. The DAC and the MCU of the power consumption are smaller than the LED array and the LED driver. In order to take household electricity into consideration the supply for the LED driver comes from the AC110V. From Table II we clearly see that a very small part of the power consumption of the system is in the control modules, which consume only 4% of the power of the whole system. As the major power consumption, 96%, is used by both the LED array and the LED driver, the first job of the future is not only to reduce the power consumption but also to enhance the illumination efficiency of the LED array. TABLE II. POWER CONSUMPTION OF THE MAJOR MODULES OF OUR DESIGN Supply Current Wireless module Figure 9. MCU with a brightness control circuit and a LED driver board Fig. 10 shows the LED driver output brightness with the LED driver output current. Our design uses the feedback from the linear ALS signal detecting the brightness, and the MCU easily judges how much output current has to be delivered to the LED driver output in order to change the brightness of the LED. We put ten sets of LED series and parallels together as a LED array, and the maximum current will be 280mA. Supply Voltage Power Consumption 53mA 5V 265.0 mW DAC and detector 3.02mA 5V 15.1 mW MCU 5.58mA 5V 27.9 mW LED driver and LED array 0.077A 110V 8.47 W Total power consumption --- --- 8.78 W VI. CONCLUSION To avoid differences in luminous decay our design uses sensor detection, feedback and automatic fine-tuning of the LED driver current by means of our software module, and thus achieves a uniform brightness of the LEDs. In our design the digital controller only consumes 4% of the power of the system in order to gain the digital fine-tuning of the uniform luminous decay of all LEDs in a LED array. REFERENCES [1] Figure 10. LED driver output brightness with LED driver output current [2] Table I shows the comparison of our design with previous designs. Our design not only uses 10 steps to control the PWM duty cycle but also extends this cycle to 100 steps and assigns a working current of a maximum of 90% that prevents both the LED from being driven too hard and also too much heat being generated. Therefore our design achieves the desired results. [3] [4] TABLE I. COMPARISON OF OUR DESIGN WITH PREVIOUS DESIGNS Previous designs Our design Accuracy of brightness control Medium High Brightness level 3 to 10 steps 100 steps Avoids the difference in luminous decay No Yes [5] [6] Table II shows the standby power consumption of the major modules of our system. We use a controller combined with a LED tube as the measurement sample. We measure the power consumption of the wireless communication module in [7] 264 F. J. Bellido-Outeirino, J. M. Flores-Arias, F. Domingo-Perez, A. Gilde-Castro, and A. Moreno-Munoz, “Building lighting automation through the integration of DALI with wireless sensor networks,” IEEE Transactions on Consumer Electronics, vol. 58, no. 1, 2012, pp. 47-52. S. Bhardwaj, T. Ozcelebi, R. Verhoeven, and J. Lukkien, “Smart indoor solid state lighting based on a novel illumination model and implementation,” IEEE Transactions on Consumer Electronics, vol. 57, no. 4, 2011, pp. 1612-1621. Ying-Wen Bai, and Yi-Te Ku, “Automatic room light intensity detection and control using a microprocessor and light sensors,” IEEE Transactions on Consumer Electronics, vol. 54, Issue 3, 2008, pp. 11731176. Dongmei Li, G. Q. Zhang, Kailin Pan, Xiaosong Ma, Lei Liu, and Jinxue Cao, “Numerical simulation on heat pipe for high power LED multi-chip module packaging,” International Conference on Electronic Packaging Technology & High Density Packaging, 2009. ICEPT-HDP '09, 2009, pp. 393-397. L.Trevisanello, F. De Zuani, M. Meneghini, N. Trivellin, E. Zanoni, and G. Meneghesso, “Thermally activated degradation and package instabilities of low flux LEDS,” IEEE International Reliability Physics Symposium, 2009, pp. 98-103. J. Hasan, and S. S. Ang, “A High-Efficiency Digitally Controlled RGB Driver for LED Pixels,” IEEE Transactions on Industry Applications, Vol. 47, no. 2011, pp. 2422-2429. Michael P. Liao, “Carrier Concentration and Junction Temperature Dependencies of Illumination Efficiency of GaN Power Light-Emitting Diodes,” Quantum Electronics and Laser Science Conference, 2007 QELS '07, 2007, pp. 1-2. [8] Yen Kheng Tan, and S. K. Panda,” Energy Harvesting From Hybrid Indoor Ambient Light and Thermal Energy Sources for Enhanced Performance of Wireless Sensor Nodes,” IEEE Transactions on Industrial Electronics, vol. 58, no. 9, 2011, pp. 424-4435. [9] Wen-Jen Chiang, Chrong-Jung Lin, Ya-Chin King, An-Thung Cho, Chia-Tien Peng, and Wei-Ming Huang, “Integrated Ambient Light Sensor With Nanocrystalline Silicon on a Low-Temperature Polysilicon Display Panel,” IEEE Transactions on Electron Devices, vol. 56, no. 4, 2009, pp. 578-586. [10] Huang-Jen Chiu, and Shih-Jen Cheng, “LED Backlight Driving System for Large-Scale LCD Panels,” IEEE Transactions on Industrial Electronics, vol. 54, no. 5, 2007, pp. 2751-2760. [11] Hyoungsik Nam, “A color compensation algorithm to avoid color distortion in active dimming liquid crystal displays,” IEEE Transactions on Consumer Electronics, vol. 56, no. 4, 2010, pp. 2569-2576. 265