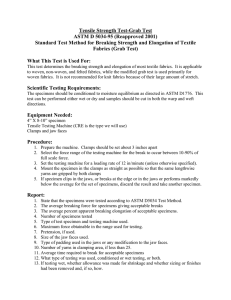

standard test methods

advertisement