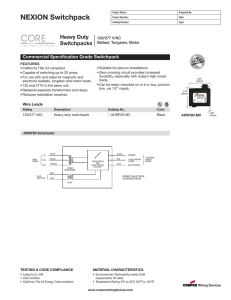

Installation, Wiring, and Specifications

advertisement