Sorting out peak

advertisement

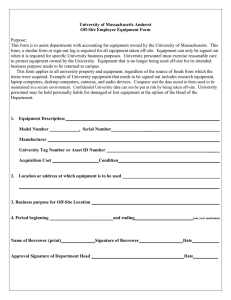

Innovation FEATURE SECTION Sorting out peak performance A vision of combining off-site construction benefits and a highperforming home led to the trial of a new building system and a new way of delivering to the market. Important lessons were learned along the way. BY VERNEY RYAN, BEACON PATHWAY INC. Second trial house THE NEW CATEGORY OF HOME project is The Warmframe system comprises steel the brainchild of New Zealand Steel and framing, insulation and thermally broken The second house in Hobsonville Point, challenges the perception some people have double-glazed windows. It can also have clad- Auckland, used a Universal Homes design that prefab is cheap. dings, linings and coatings added in the factory. with Warmframe to trial two alternative It began with a vision of a home that would methods of off-site construction – 2D walls perform to a high standard – meeting the Trial and demonstration and 3D modules for framing, insulation and Homestar 8 rating and Beacon’s HSS High Next, a trial and demonstration phase windows – and assess potential application Standard of Sustainability – and be delivered tested the system’s buildability and cost in a medium-density design. through off-site construction with its poten- of construction, solved technical issues It was assembled inside a factory, trans- tial cost and time savings. in a real-life situation and checked the ported to site, constructed and finished performance of the building system. with claddings and linings using traditional Five partners joined New Zealand Steel in the project – Fletcher Aluminium, The first trial was part of PrefabNZ’s HIVE in methods. This provided an insight on Frametek-RFS, InsulPro and Resene, with Christchurch and used Salmond Architecture’s delivery to the volume homebuilder market, Beacon Pathway facilitating the process. High Performance Houses design – flexible and working in a business as usual environ- modules suited to off-site construction – with ment. Full thermal testing and monitoring of the new Warmframe system. this house has yet to be completed. Innovation phase The project began by bringing together The house was fully built in the factory – the partners’ technical knowledge and framing, insulation, roofing, cladding, lining Off-site construction learnings understanding of their own products to and windows – and transported by truck to The two trials provided key learnings on develop a new building system. The result the site to be finished. successful off-site construction. – Warmframe – is a steel-frame building Once complete, thermal testing and system that can be built as walls, sections imaging of walls and ceilings were under- Both trials used existing house designs and or entire buildings in a factory and has a taken. The house was open to the public this proved counterproductive to the usual R-value significantly above Building Code during 2013 and then sold, testing consumer advantages of the off-site manufacturing minimum requirements. reaction and barriers to prefabrication. process. Complex architectural features, Needs to be design led Build 143 — August/September 2014 — 59 Innovation PHOTOGRAPH – MANNERING AND ASSOCIATES PHOTOGRAPHY FEATURE SECTION The HIVE house is transported to site as an entire building. such as wing walls, can add considerable kept track of construction material, enabling were good reasons for this, and it could be time and cost. greater scrutiny of materials used and more improved with further delivery to scale, but efficient supply and delivery. the conclusion is that off-site construction Preset material choices were also not well suited to optimising off-site manufac- needs to cover the entire process from design turing. For example, vertical cedar cladding A matter of scale required additional timber framing attached Testing various scales of off-site construc- to the steel framing for fixing, adding cost tion – entire 3D house, 2D walls, 3D modules Prefabrication perceived as low cost and complexity. – enabled some high-level conclusions on The experience of selling the HIVE house efficiency of scale. brought home a crucial barrier to off-site A design-led process would have prioritised a cladding system more suited to The 3D components were significantly efficient off-site manufacturing and the steel more complex to construct and transport structure in this instance. than the panelised components and also Needs to be well organised took up more factory floor space. to on-site fit-out. construction – the general perception that a prefabricated house should be cheap. The real estate agents reported that people viewed a prefabricated house as being a Leasing and setting up a factory was rela- However, working in 3D means there is tively simple and cost-effective. Using a good potential for more of the finish to be done process engineer helps establish stream- in the factory. The HIVE house, for example, This suggests that, while there are produc- lined and efficient ergonomic construction was fully enclosed and lined in the factory. tivity, efficiency, quality and cost benefits processes. step above a portacom, despite being well appointed. Transportation of the 3D components, from whole-house prefabrication, a partial Quality and productivity were substan- even as modules, was comparatively inef- prefabrication approach – for example, wall tively better in the factory than on site. ficient given the volume being transported panels – may be a more acceptable option Having the correct materials and tools and the need for specialised contractors. in the market while still realising some of available in the weatherproof, single-level the benefits. factory environment and a dedicated, expe- It’s not business as usual rienced workforce with set work hours can Several challenges arose from delivering an New language needed significantly accelerate construction. innovation using an already busy workforce It also suggests that the industry needs to with business as usual constraints. develop more sophisticated language to Working in a factory can also improve safety and further reduce compliance costs. The natural tendency to resort to the In particular, second-storey windows can be usual way of doing things works against the Using the term ‘prefabrication’ may be less installed at floor level without the encum- introduction of innovation and the search preferable than talking about off-site brance of scaffold. for out-of-the-box solutions. construction, and the New Category of Home Factory set-up can also improve goods and The result was that the on-site construction services delivery. A goods inwards system phase was less efficient than expected. There 60 — Build 143 — August/September 2014 describe these innovations. partners are dropping the term prefabrication from their lexicon.