A Universal and Optimized Embedded System to

Control Firing Angle of Thyristors with Double-Sided

Isolation

Muhammad Usman Rafique

Department of Electrical Engineering

COMSATS Institute of Information Technology

Lahore, Pakistan

usmanrafique@ciitlahore.edu.pk

Abstract--This paper describes the implementation of a

double sided isolated, economical, easy to implement and

optimized approach to design a digital firing angle control

system for silicon controlled rectifiers (SCR) and triacs.

Currently designed circuits for this purpose use keypads to

take input from user and also use uneconomical ways to

implement zero crossing circuitry. This proposed design

eliminates the keypad and implements an economical and

cost–effective solution that helps industrial as well as home

users. The method proposed in this paper is of universal

nature and improves the design by applying the double sided

isolation and removes the pulse transformer that is not only

expensive but also provides the means of magnetic coupling

that may be harmful for the controller circuitry. The design

proposed in this paper is of universal nature that can be used

to control the home as well as industrial loads of either the

AC system running either 50 Hz or 60 Hz standard or the DC

system. In addition to that, proposed design is fully

compatible with 50 Hz and 60 Hz power systems.

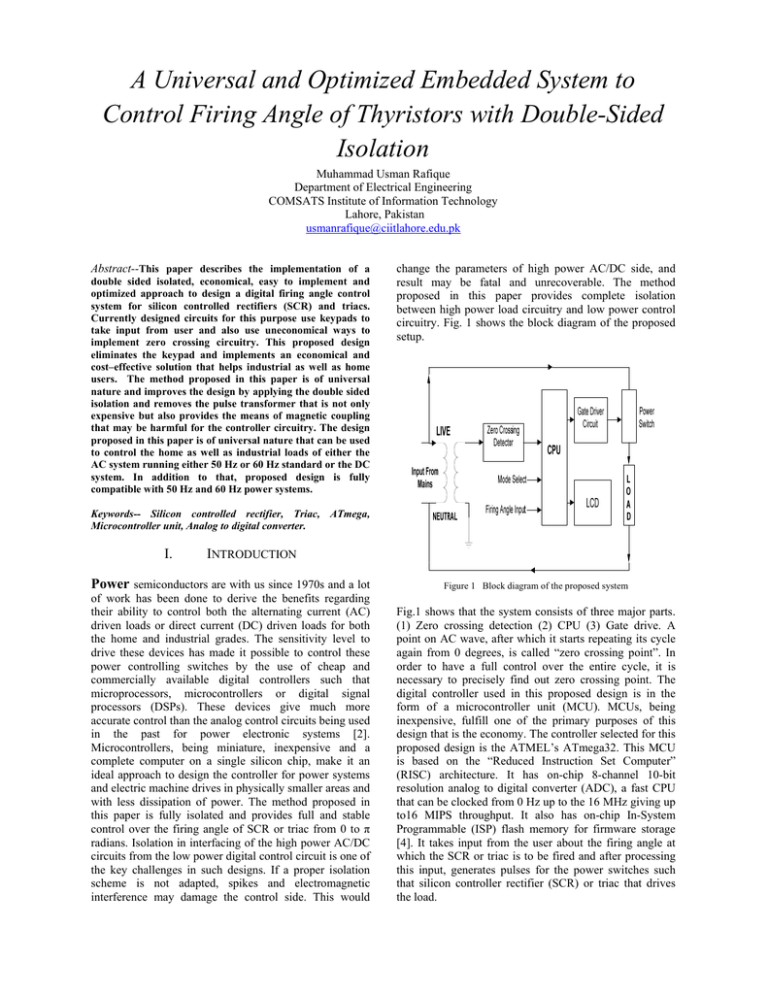

change the parameters of high power AC/DC side, and

result may be fatal and unrecoverable. The method

proposed in this paper provides complete isolation

between high power load circuitry and low power control

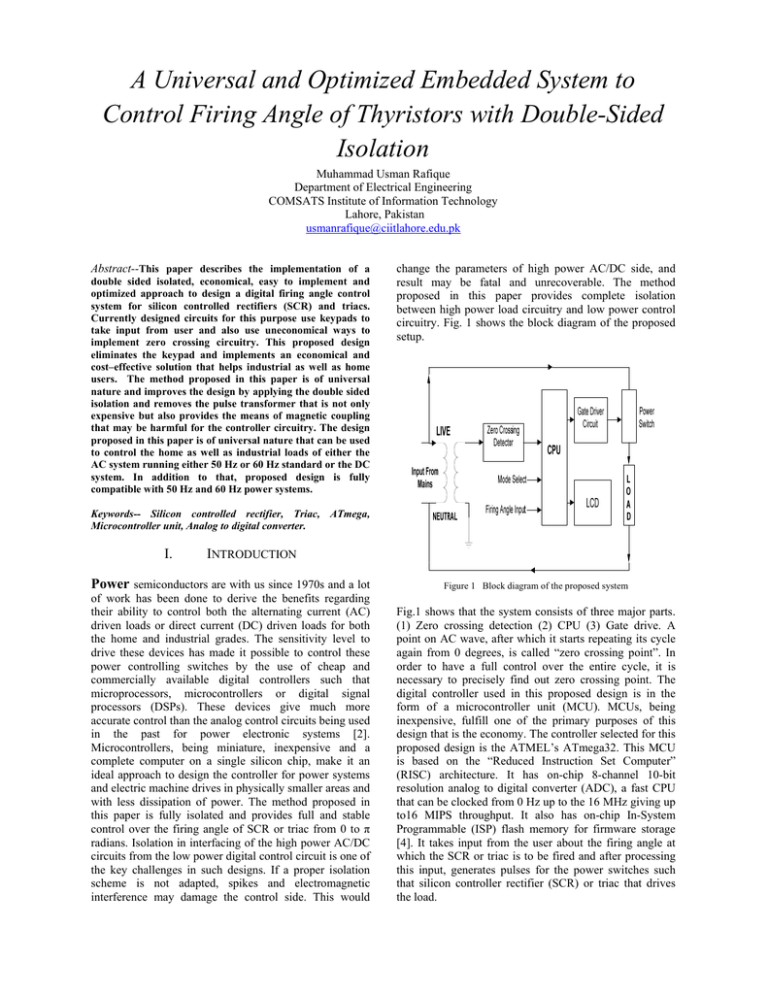

circuitry. Fig. 1 shows the block diagram of the proposed

setup.

Keywords-- Silicon controlled rectifier, Triac, ATmega,

Microcontroller unit, Analog to digital converter.

I.

INTRODUCTION

Power semiconductors are with us since 1970s and a lot

Figure 1 Block diagram of the proposed system

of work has been done to derive the benefits regarding

their ability to control both the alternating current (AC)

driven loads or direct current (DC) driven loads for both

the home and industrial grades. The sensitivity level to

drive these devices has made it possible to control these

power controlling switches by the use of cheap and

commercially available digital controllers such that

microprocessors, microcontrollers or digital signal

processors (DSPs). These devices give much more

accurate control than the analog control circuits being used

in the past for power electronic systems [2].

Microcontrollers, being miniature, inexpensive and a

complete computer on a single silicon chip, make it an

ideal approach to design the controller for power systems

and electric machine drives in physically smaller areas and

with less dissipation of power. The method proposed in

this paper is fully isolated and provides full and stable

control over the firing angle of SCR or triac from 0 to π

radians. Isolation in interfacing of the high power AC/DC

circuits from the low power digital control circuit is one of

the key challenges in such designs. If a proper isolation

scheme is not adapted, spikes and electromagnetic

interference may damage the control side. This would

Fig.1 shows that the system consists of three major parts.

(1) Zero crossing detection (2) CPU (3) Gate drive. A

point on AC wave, after which it starts repeating its cycle

again from 0 degrees, is called “zero crossing point”. In

order to have a full control over the entire cycle, it is

necessary to precisely find out zero crossing point. The

digital controller used in this proposed design is in the

form of a microcontroller unit (MCU). MCUs, being

inexpensive, fulfill one of the primary purposes of this

design that is the economy. The controller selected for this

proposed design is the ATMEL’s ATmega32. This MCU

is based on the “Reduced Instruction Set Computer”

(RISC) architecture. It has on-chip 8-channel 10-bit

resolution analog to digital converter (ADC), a fast CPU

that can be clocked from 0 Hz up to the 16 MHz giving up

to16 MIPS throughput. It also has on-chip In-System

Programmable (ISP) flash memory for firmware storage

[4]. It takes input from the user about the firing angle at

which the SCR or triac is to be fired and after processing

this input, generates pulses for the power switches such

that silicon controller rectifier (SCR) or triac that drives

the load.

Figure 2 Block diagram of ATMEL’s ATmega32 RISC Microcontroller

The firmware calculates the exact timing to generate the

triggering signals. An optocoupler isolates the MCU

circuitry from the power switch or load circuitry. The

optocoupler used in this proposed design itself has a triac

at its output stage. Input side of the optocoupler is driven

by the ATmega that drives the triac of the optocoupler.

The triac of the optocoupler, being optically isolated from

the digital controller circuitry, drives the gate of SCR or

triac in turn. Driving the gate of an SCR or of a triac

needs special care and attention. Gate current needs to be

higher than the nominated ratings of the devices to

properly trig the device and it should be supplied slightly

more than the turn on time ‘ton’ of the device. These

specifications are necessary to meet to bring the device

from blocking state to the conduction state. Gate driving

circuitry should be isolated from the control circuitry to

avoid any reverse flow of current through gate of

SCR/triac to the control circuitry or to avoid any

unwanted electromagnetic interference (EMI) resulted

from the triggering of devices other than the zero crossing

point instant. Proposed method is equally suitable for

SCR and triacs of power ratings up to the 1500 Watts

with complete isolation between gate driving circuitry and

load to be driven. This isolation problem is solved using

commonly available optotriacs and optothyristors.

II.

EXPERIMENTAL SETUP

The proposed design is implemented and fully tested

using prototype circuit boards. Heart of the system is

ATMELS’s ATmega32 microcontroller unit. This MCU

contains on-chip analog to digital converter (ADC) with

10-bits resolution, which is at the input stage of the

system.

A.

Implementation of Zero Crossing Detector

To have full control over the firing angle of the SCR/triac

(from 0 to π radians), it is necessary to precisely detect the

zero crossing of the sinusoidal input. Conventional zero

crossing detectors cannot distinguish between start of

positive half cycle or negative half cycles [2]. Schematic

of the zero crossing circuit that was implemented is

shown in fig. 3.

Figure 3

Zero crossing circuit with input transformer

The transformer T1 at the input side is used for two

purposes. Firstly it scales down the mains alternating

voltage to a lower and safer value up to the 6 to 9 volts

rms. This gives peak voltage of 8.46 = √2*6 volts up to

12.728 = √2*9 volts, respectively. Secondly it provides

the galvanic isolation between mains and zero crossing

detection circuitry that is another key goal of the proposed

design. It is necessary that the output at the secondary of

T1 remain in-phase with the input on its primary. This

scaled down and isolated AC input is then scaled down

further by using a resistor divider network consisting on

R1 and R2. R1 and R2 are of equal values. If Vin is the

voltage coming out of the transformer T1 and Vout is the

voltage coming out from the divider network, then Vout

can be computed from the following expression.

Vout = (R2/R1)* Vin

(1)

Advantage of this scheme is twofold; it not only provides

isolation but also makes the system free of error against

the fluctuation on mains voltage. For example, if mains

voltage is at nominal 311.13 peak volts (220V rms), then

T1 outputs 12.73 peak voltages if a 220 rms to 9 rms

transformer is used. These voltages are scaled down by

divider network to 6.35 peak voltages. If the voltages on

mains are changed to 339.41 peak (240V rms) then output

of T1 will be 13.88 peak voltages. These voltages are

halved to 6.94 peak voltages by the resistor divider

network. Similarly, 282.84 peak voltages (200V rms)

will give 11.57 peak voltages at the output of T1 that is

halved by divider network to 5.78 peak voltages. Hence a

change of ± 28.28 volts on the mains creates the

fluctuation of voltage at the base of Q1 by only 0.58 volts.

Calculations of the results with 110 volts standard of

power system are shown in TABLE I.

TABLE I.

Calculations of different voltage levels with 110V mains

supply

Parameter

Value (peak voltages)

Max. mains voltage

339.41

Min. mains voltage

282.84

Max. voltage at output of T1

13.88

Min. voltage at output of T1

11.57

Max. voltage divider output

6.94

Min. voltage divider output

5.78

This scaled down version of mains voltage is half-wave

rectified using D1 and is given to the base of Q1. Fig. 4

shows the result of zero crossing detector circuitry.

B.

Generating Firing Pulse

This negative going edge of square wave shown in fig. 4

interrupts the MCU that in turn reads out the latest ADC

reading as information about firing angle. This system can

be configured in either 50 Hz mode or 60 Hz mode by

user. The presented results were drawn by operating the

system in 50 Hz mode due to the national standard of

power transmission in Pakistan.

III.

Firmware of the system is written entirely in C language

due to its friendly execution on ATmega32 CPU. The

CPU used in this proposed design has ‘C friendly’

architecture with a large register file [4] to store the

variables in registers for faster access. Whenever zero

crossing is detected on the mains power line, CPU is

interrupted and the latest values of firing delay and firing

angle are used to generate gate triggering pulses. ADC

reading is converted into the firing angle and is displayed

on LCD. The relationship between ADC output and firing

angle is given in (2). If ADC is the output from analog to

digital converter and α is the firing angle such that α

ranges from 0 to 180 degrees, then,

α = ADC/5.66

Zero Crossing Output

(2)

As ADC of ATmega32 is of 10-bit resolution hence the

maximum value from the ADC with +5 volts reference

will be 1023. Therefore, a scaling down factor of 5.66 is

used. Eq. (2) gives 180.74 when potentiometer is fully

rotated in clockwise direction (subjected to the position of

potentiometer with respect to user) and gives 0 for

counter clockwise direction. ADC reading is converted

into a delay after which firing pulse is to be generated.

Relationship between ADC reading and firing angle delay

is shown in (4). If ADC is output of ADC and d is the

delay in microseconds, then,

d = (ADC*5)*1.95

(3)

1.95 here is the scaling up factor for the ADC reading and

5 is the reference voltage. Hence for ADC = 1023, the

delay d will be 9974.25 microseconds. MCU generates

firing pulses on its output port with on-time of 100

microseconds. Microcontroller generates pulses for both

the positive as well as for the negative half cycles.

IV.

Figure 4

The Firmware

Gate Driver

I/O ports on ATmega32 can source only 10 milliampere

of current on each pin [4]. This current is not enough to

fire the SCR/triac directly. Sensitive gate switches (those

with gate trigger current is less than 200 microamperes

[3]) can be fired directly but the problem of isolation will

still be existing. Conventionally this problem is resolved

using pulse transformers. In this proposed design, pulse

transformer is avoided due to two main reasons. Firstly it

is bulkier and needs special footprints on the printed

circuit boards. Secondly it does not provide true isolation

between control circuitry and gate of the power switch i.e.

SCR or triac. As the goal of this proposed design is to

provide a solution that is compact and fully isolated from

mains, technique to drive the SCR/triac by a pulse

transformer does not seem good and economical in

anyway. MOC3021 is the solution to these problems

which is an optocoupler [5]. It drives high power triacs or

SCR to control the actual load on AC mains and also

provides electrical isolation between gate drive and AC

mains. If SCR is replaced with a triac, it would conduct in

both positive and negative half cycles. In this condition

triac will be fired in first and third quadrants only. Triacs

are sensitive in first and third quadrants when both MT2

and the gate terminals are receiving negative current [3].

Triac’s modes of firing or its operating quadrants are

shown in fig. 5.

With 2N6075 triac, different waveforms were obtained at

different firing angles across an inductive load which was

a single–phase AC motor. Fig. 7 shows the waveform

across the motor along with firing pulses. Upper

waveform in this figure is the voltage across motor and

lower waveform shows the firing pulses.

Figure 7 Voltage waveform across resistive load controlled by triac

fired at 90 degrees

VI.

Figure 5 Four operating quadrants of a triac

V.

EXPERIMENTAL RESULTS

This proposed design has been fully tested and verified by

driving incandescent lamps, permanent magnet direct

current motors and single phase induction motors up to

1000 watts power ratings. Circuit is capable to fire the

SCR/triac at any angle ranging from 0 to 180 degrees

without any noise or fluctuations on main lines. Fig. 6

shows the output waveform across a resistive load

controlled with BT152 SCR along with mains waveform

at 0 degrees firing angle. The upper voltage waveforms in

this figure are the voltage across resistive load and lower

waveform are the mains voltage.

CONCLUSIONS

The proposed design is an economical, easy to realize,

user friendly and is fully isolated from main supply line at

both the input and output stages to nullify the effect of

noise and electromagnetic interference over the mains

power line. Design is of universal nature that can be used

with 50 Hz as well as with 60 Hz power distribution

standards and can also deliver both AC (in case of triac)

and DC (in case of silicon controller rectifier) power to

load. The method proposed in this paper is fully software

upgradable to alter the design to drive more devices.

Components used to implement this proposed design are

also not critical. It can be implemented with cheap and

all-time available components providing a ready-to-use

solution.

VII.

REFERENCES

[1] P. Pavana Kumar, R. Parimelalagan, and B. Ramaswami, “A

Microprocessor-Based DC Drive Control Scheme Using Predictive

Synchronization,” IEEE Trans. Ind. Elect. Vol 40, pp . 445-452,

Aug. 1993.

[2] XU Wuxiong, “Design of Thyristor Digital Trigger Circuit Based on

Microcontroller Unit,” The 1st International Conference on

Information Science and Engineering (ICISE2009).

[3] On Semiconductors, Thyristor Theory and Design Considerations,

HBD855/D, pp. 11, pp. 38-39.

[4] Atmel Corporation, ATmega32 datasheet.

[5] Texas Instruments, MOC3021 datasheet.

[6] Muhammad H. Rashid, Power Electronics (Circuits, Devices, and

Applications), 3rd ed., Pearson Prentice Hall, 2006, pp. 339.

Figure 6 Voltage waveform across resistive load controlled by SCR

fired at 150 degrees