mp1000 cone crusher data sheet

advertisement

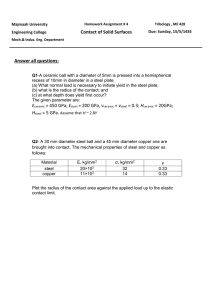

MP1000 CONE CRUSHER DATA SHEET Item Unit Manufacturer Type Model No./Size Data Metso Cone Crusher MP1000 PERFORMANCE Close side setting Countershaft speed WK2 of Crusher GENERAL TECHNICAL DATA Feed opening Weights (approx.) Total: Main frame assembly Bowl assembly, bowl liner & hopper Head assembly, mantle & feed plate Eccentric assembly Adjustment ring, clamping ring, clamping cylinders & adjustment mechanism Countershaft assembly & sheave Mantle Bowl liner Hydraulic power unit Package lube system - air cooled Dry Full oil tank Package lube system - water cooled Dry Full oil tank Skid mounted air coolers Heaviest for erection Mainframe, adjustment ring, tramp release system, eccentric assembly, socket & countershaft assembly Heaviest for maintenance Bowl assembly Mounting mm RPM kg.m2 8 - 38 700 - 895 743 Application dependent kg kg kg kg kg 150,494 46,801 33,112 17,573 8,820 kg 30,990 kg kg kg kg 4,113 5,538 (application dependent) 5,837 (application dependent) 1,250 kg kg 3,493 5,126 kg kg kg 4,046 5,679 2,731 kg 93,844 kg 33,112 (application dependent) Directly on 4 sole plates; concrete or steel foundation MAIN FRAME Revision 20110225 Page 2 of 7 MP1000 CONE CRUSHER DATA SHEET Material of construction Diameter (at the top) Base dimension Height Weight Arm liners material of construction Number Weight Thickness Main frame liner material of construction Weight Side liners Thickness mm mm mm kg kg mm kg Grade 80-50, carbon steel casting 4,059 3,899 x 3,899 2,305 42,791 Ni-Hard cast iron 3 218 each 50 T1 steel 1,950 mm 20 kg mm ASTM A668/A668M Class LH, forged steel 4,418 640 X 1,910 kg mm Cast carbon steel, grade 100-80 21,541 4,267 kg mm Cast ductile iron, grade 80-55-06 3,690 6,620 mm mm kg Cast carbon steel, grade 90-60 Manganese steel Up to 150 356 32,168 (application dependent) kg mm Cast carbon steel, grade 90-60 9,779 2,286 MAIN SHAFT Material of construction Weight Diameter X Length ADJUSTMENT RING Material of construction Weight Diameter (max.) CLAMP RING Material of construction Weight Diameter (max.) BOWL Material of construction Liner material of construction Thickness Vertical range of adjustment Weight (bowl & bowl liner) HEAD Material of construction Weight Diameter Revision 20110225 Page 3 of 7 MP1000 CONE CRUSHER DATA SHEET Feed plate material of construction Weight Mantle material of construction Thickness Weight Locking bolt material of construction Weight Upper head bushing material of construction Weight Diameter (outer) Lower head bushing material of construction Weight Diameter (outer) ECCENTRIC Material of construction Diameter (inner) Diameter (outer) Diameter (at flange) Length Weight Eccentric bushing material of construction Diameter (inner) Diameter (outer) Length Weight Eccentric sleeve material of construction Diameter (inner) kg kg kg Manganese steel 340 Manganese steel Application dependent 5,538 (application dependent) Cast steel 445 Aluminum bronze kg mm 159 980 Lead tin bronze casting kg mm 458 1,199 mm Cast gray iron, ASTM class 45C 700 1,000 1,470 885 3,220 Lead tin bronze casting 641 700 870 456 4140 steel welded steel plate 950 Diameter (outer) mm 1,000 Length mm 640 Weight kg 539 kg Cast steel and Lead (Pb) 3,605 Counterweight material of construction Weight COUNTERSHAFT Countershaft housing material of construction Weight Countershaft material of construction Length Revision 20110225 mm mm mm mm kg mm mm mm kg Cast steel, grade 70-36 kg mm 1,392 AISI 1045 carbon steel 2,245 Page 4 of 7 MP1000 CONE CRUSHER DATA SHEET Diameter Weight Countershaft bushings material of construction Bushing diameter (inner) Bushing diameter (outer) mm kg 200 550 Lead tin bronze casting mm mm 200 250 BEVEL GEAR / PINION GEAR Material of construction Design Pitch diameter Number of teeth Diametrical pitch Hardness Heat treatment Face width Mean spiral angle Pressure angle AGMA durability rating AGMA strength rating AGMA quality AGMA standard mm Rockwell C mm Degree Degree HP HP AISI 4340 forged steel / AISI 4320 forged steel Spiral 1,659 / 574 55 / 19 0.842 50-54 / 58-64 Induction / Carburized 250 25 20 7,760 8,480 / 5,640 8 2003-B97 HYDRAULIC SYSTEM & SETTING ADJUSTMENT SYSTEM Crusher hydraulic system Tank capacity liters 568 Oil flow, 60 Hz LPM 242 Oil flow, 50 Hz LPM 204 Oil pressure (max.) bar 220 Hydraulic pump Double vane Hydraulic power unit motor, quantity 1 NEMA design 50 HP, 1800 RPM, 60 Hz IEC design 37 kW, 1500 RPM, 50 Hz Setting adjustment system Operating pressure (max.) bar 220 Number of hydraulic adjustment 4 motors Hydraulic motor manufacturer PARKER Adjusting ring gear material of T-1 Plate construction Revision 20110225 Page 5 of 7 MP1000 CONE CRUSHER DATA SHEET Number of teeth Thickness Adjustment pinion gear material of construction Number of teeth Thickness Tramp release & clearing cylinders Quantity Bore x stroke Hydraulic oil Maximum operating temperature Viscosity Viscosity index Start-up volume (approx.) LUBRICATION SYSTEM Crusher lubrication system Oil flow, 60 Hz Oil flow, 50 Hz Oil tank capacity Working pressure Cooling water (optional) Heat dissipation Immersion heaters Lubrication air-to-oil cooler (standard) Manufacturer Model (typical) Motor, quantity NEMA design IEC design Lubrication water-to-oil cooler (option) Manufacturer Model (typical) Tube material Net surface area, each cooler Lubrication pump Manufacturer Working pressure Motor, quantity NEMA design Revision 20110225 mm 120 64 AISI 1045 mm mm Degree C liters LPM LPM liters bar LPM m2 bar 20 108 16 279 x 250 ISO VG 32 oil 60 28.8 to 35.2 cSt @ 40 degree C 140 minimum 625 757 631 1,893 14 288 @ 27 degree C 8,400 BTU/min (147,577 watts) Qty. 2, 4 kW each Dependent on site conditions Young Two OCS-3100 Dependent on site conditions 20 HP, 1200 RPM, 60 Hz 15 kW, 1000 RPM, 50 Hz Dependent on site conditions ITT American Standard 8066 90/10 CuNi 13 Permco 14 2 total; 1 duty & 1 standby 30 HP, 1800 RPM, 60 Hz Page 6 of 7 MP1000 CONE CRUSHER DATA SHEET IEC design Lubrication oil filter housing Lubrication oil filters Manufacturer Separation size Lubrication oil specification Maximum operating temperature Viscosity Viscosity index POSITIVE PRESSURE DUST SYSTEM Blower manufacturer Air flow Motor, quantity NEMA design IEC design micron Degree C 3 m /min 22.5 kW, 1500 RPM, 50 Hz 2 total; 1 duty & 1 standby Four elements per housing Nelson 25 ISO VG 150 (E.P. rated) 60 135 to 165 cSt @ 40 degree C 90 minimum American Fan Company 14.3 @ 60 Hz 1 3 HP, 3600 RPM, 60 Hz 2.2 kW, 3000 RPM, 50 Hz INSTRUMENTATION Refer to instrument list TOOLS SUPPLIED Refer to tools list PAINT Type Color Water base Metso Minerals’ beige SHIPPING INFORMATION Refer to estimated shipping list Revision 20110225 Page 7 of 7