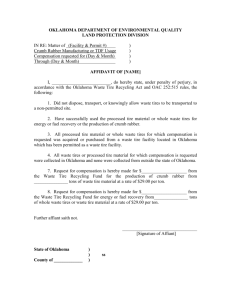

Tires and Tire Rubber - the Texas Department of Transportation FTP

advertisement