chapter 9 second-law analysis for a control volume

advertisement

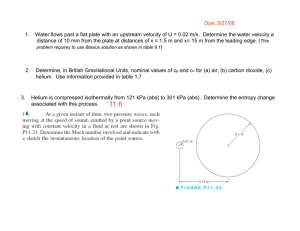

CHAPTER 9 SECOND-LAW ANALYSIS FOR A CONTROL VOLUME blank SONNTAG/BORGNAKKE STUDY PROBLEM 9-1 9.1 An ideal steam turbine A steam turbine receives 4 kg/s steam at 1 MPa 300oC and there are two exit flows, 0.5 kg/s exits at 150 kPa and the rest exits at 15 kPa. Assume the turbine is ideal, adiabatic and that we can neglect kinetic energy everywhere. We want to determine the total power output. Solution: C.V. Turbine, steady operation adiabatic and reversible. . . . Continuity Eq.6.9: m1 = m2 + m3 ; . . . . Energy Eq.6.10: m1h1 = m2h2 + m3h3 + WT . . . . Entropy Eq.9.7: m1s1 + Sgen = m2s2 + m3s3 . Process: Sgen = 0 1 2 3 WT If we separately applied the second law to section 1 to 2 and section 2 to 3 we get . . . Section 1 to 2: m1s1= m2s2 + m3s2 ⇒ s1 = s2 . . Section 2 to 3: m3s2 = m3s3 ⇒ s2 = s3 s1 = s2 = s3 that is constant s through turbine State 1 from Table B.1.3: h1 = 3051.15 kJ/kg, s1 = 7.1228 kJ/kg K, State 2 (P, s) : s2 < sg so this state is two-phase x2 = (s2 – sf)/ sfg = (7.1228 – 1.4335) / 5.7897 = 0.98266, h2 = 467.08 + x2 × 2226.46 = 2654.9 kJ/kg State 3 (P, s) : s3 < sg so this state is two-phase x3 = (s3 – sf)/ sfg = (7.1228 – 0.7548) / 7.2536 = 0.87791, h3 = 225.91 + x3 × 2373.14 = 2309.3 kJ/kg Now we can substitute into the energy equation . . . . WT = m1h1 – m2h2 – m3h3 = 4 × 3051.15 - 0.5 × 2654.9 – 3.5 × 2309.3 = 2795 kW P 1000 150 15 T 300 1 2 3 v 120 111 54 1000 kPa 1 200 kPa 150 kPa 15 kPa 2 3 s SONNTAG/BORGNAKKE STUDY PROBLEM 9-2 9.2 An ideal air compressor An air compressor in a gas station takes in a flow of ambient air at 100 kPa, 17oC and compresses it to 1000 kPa in a reversible adiabatic process. We want to know the specific work required and the exit air temperature. Solution: . C.V. Air compressor, steady state, single flow through it and we assume adiabatic Q = 0. . . . Continuity Eq.6.11: mi = me = m, . . . Energy Eq.6.12: mhi = mhe + WC, . . . Entropy Eq.9.8: msi + Sgen = mse . Process: Reversible Sgen = 0 P T e e i i v s Use constant specific heat from Table A.5, CPo = 1.004 kJ/kg K, k = 1.4 Entropy equation gives constant s which give the relation in Eq.8.32 k-1 P k si = se => Te = Ti ( e) Pi 0.2857 1000) Te = 290 ( = 559.9 K 100 The energy equation per unit mass gives the work term wc = hi – he = CPo (Ti – Te) = 1.004 (290 – 559.9) = -271 kJ/kg Remark: This is an unrealistic high temperature for the exit state. The compressor handles a relatively small flow rate so there is a heat transfer (loss) that should be accounted for. SONNTAG/BORGNAKKE STUDY PROBLEM 9-3 9.3 A cross-flowing heat exchanger with entropy generation An ordinary radiator receives 0.2 kg/s hot water at 80oC, 110 kPa from a pipe and the water exits at 70oC. The radiator heats the air outside of it so the air rises up (natural convection) pulling colder air towards the radiator behind it. This acts as a two fluid heat exchanger so assume the air comes in at 20oC and leaves the radiator at 30oC. We want to know the mass flow rate of air and the total entropy generation rate in the process. Solution: The schematic may look like this: 2 3 air . . . . Energy Eq.6.10: mH2O h1 + mAIR h3 =. mH2O h2 + mAIR h4 . . . . Entropy Eq.9.7: mH2O s1 + mAIR s3 + Sgen = mH2O s2 + mAIR s4 Process: Constant pressure for air From B.1.1: h1 = 334.88 kJ/kg; s1 = 1.0752 kJ/kg K h2 = 292.96 kJ/kg; s2 = 0.9548 kJ/kg K Using A.5: h4 - h3 = Cp(T4 – T3) = 1.004(30 – 20) = 10.04 kJ/kg T P s4 - s3 = Cp ln ( 4 ) – R ln ( 4 ) T3 P3 30 + 273 = 1.004 ln – 0 = 0.03368 kJ/kg K 20 + 273 From energy equation . . h -h 334.88 - 292.96 mAIR = mH2O 1 2 = 0.2 = 0.835 kg/s h4 - h3 10.04 From entropy equation . . . Sgen = mH2O(s2 - s1) + mAIR(s4 - s3) = 0.2 (0.9548 – 1.0752) + 0.835 × 0.03368 = – 0.02408 + 0.02812 = 0.004 kW/K 4 1 water SONNTAG/BORGNAKKE STUDY PROBLEM 9-4 9.4 Mixing process generates entropy A de-superheater works by injecting liquid water into a flow of superheated steam. With 2 kg/s at 300 kPa, 200oC steam flowing in, what mass flow rate of liquid water at 20oC should be added to generate saturated vapor at 300 kPa? We also want to know the rate of entropy generation in the process. C.V. De-superheater, no external heat transfer and no work. T 2 1 Desuper heater 1 300 kPa 3 3 2 Continuity Eq.6.9: Energy Eq.6.10: Entropy Eq.9.7: Process: . . . m . . 1 + m2. = m3 ; . . m . 1h1 + m . 2h2 = m . 3h3 = .( m1 + m2 ) h3 m1s1 + m2s2 + Sgen = m3s3 P = constant, W = 0 and Q = 0 All the states are specified (approximate state 2 with saturated liquid 20oC) kJ kJ kJ kJ B.1.3: h1 = 2865.54 , s1 = 7.3115 ; h = 2725.3 , s3 = 6.9918 kg kg K 3 kg kg K kJ kJ B.1.2: h2 = 83.94 , s2 = 0.2966 kg kg K . . Now we can solve for the flow rate m2 from the energy equation having eliminated m3 by the continuity equation . . h -h 2865.54 - 2725.3 m2 = m1 1 3 = 2 = h3 - h2 2725.3 - 83.94 0.1062 kg/s . . . m3 = m1 + m2 = 2.1062 kg/s Generation is from equation . the entropy . . . Sgen = m3s3 – m1s1 – m2s2 = 2.1062 × 6.9918 – 2 × 7.3115 – 0.1062 × 0.2966 = 0.072 kW/K s SONNTAG/BORGNAKKE STUDY PROBLEM 9-5 9.5 Filling process of a non-empty pressure tank Assume an air tank has 40 L of 100 kPa air at ambient temperature 17oC. The adiabatic and reversible compressor is started so it charges the tank up to a pressure of 1000 kPa and then it shuts off. We want to know how hot the air in the tank gets and the total amount of work required to fill the tank. Solution: C.V. Compressor and air tank. P s=C 2 T T2 400 290 1, i v Continuity Eq.6.15: Energy Eq.6.16: 2 100 kPa 1, i s m2 - m1 = min m2u2 - m1u1 = 1Q2 - 1W2 + minhin ⌡dQ/T + 1S2 gen + minsin Entropy Eq.9.12: m2s2 - m1s1 = ⌠ Process: Adiabatic 1Q2 = 0 , Process ideal 1S2 gen = 0 , s1 = sin ⇒ m2s2 = m1s1 + minsin = (m1 + min)s1 = m2s1 ⇒ s2 = s1 Constant s ⇒ Eq.8.28 o o sT2 = sTi + R ln(P2 / Pi) o sT2 = 6.83521 + 0.287 ln( 10 ) = 7.49605 kJ/kg K ⇒ T2 = 555.7 K , u2 = 401.49 kJ/kg Interpolate in table A.7 m1 = P1V1/RT1 = 100 × 0.04 / (0.287 × 290) = 0.04806 kg m2 = P2V2/RT2 = 1000 × 0.04 / (0.287 × 555.7) = 0.2508 kg ⇒ min = 0.2027 kg 1W2 = minhin + m1u1 - m2u2 = min(290.43) + m1(207.19) - m2(401.49) = -31.9 kJ Remark: The high final temperature makes the assumption of zero heat transfer poor. The charging process does not happen very fast so there will be a heat transfer loss. We need to know this to make a better approximation about the real process. SONNTAG/BORGNAKKE STUDY PROBLEM 9-6 9.6 Flow of liquid through a tank and nozzle A tall tank of cross section area 5 m2 receives a flow of 50 kg/s water at 101 kPa, 20oC with negligible kinetic energy. At the bottom of the tank is a nozzle pointing downwards with the smallest diameter of 0.1 m. Assume a reversible flow with no change in temperature and find the exit velocity and the water level height H that gives steady state in the tank. Solution: C.V.: Tank and its water. No work or heat transfer. To have steady state the mass flow rate out must be the same as the inlet mass flow rate. Entropy Eq.9.8: . . min = mex = (ρAV)nozzle . . m(h + V2/2 + gZ)in = m(h + V2/2 + gZ)ex . . . msin + Sgen = msex Process: Reversible and Vin ≅ 0 , Zin − Zex = Η, ρ = 1/v ≅ 1/vf Continuity Eq.6.3, 6.11: Energy Eq.6.12: For the reversible process the second law leads to Eq.9.13 e ⌠ v dP = 0 (same P and constant v) hex - hin = ⌡ i With zero work the energy equation therefore becomes Bernoulli Eq.9.17 g(Zin − Zex) = g H = V2ex/2 From the continuity equation . . min 4minv 4 × 50 × 0.001002 = = = 6.379 m/s Vex = ρ Anozzle ðD2 ð 0.12 From Bernoullis equation we then get H = V2ex/2g = . min . mex 40.69 = 2.074 m 2 × 9.81 H SONNTAG/BORGNAKKE STUDY PROBLEM 9-7 9.7 A mathematical solution to an unsteady problem The water tank in study problem 9.6 has at one point a water level of 2.5 m when the inlet water flow is turned off. Estimate the time it will take to empty the tank. Solution: To solve the problem we neglect the volume and height of the nozzle so the tank volume is the tank cross sectional area times the height. dmtank . Continuity Eq.: = −mex = −(ρAV)nozzle dt mtank = ρ V = ρAtank H Energy equation is the same as in study problem 9.6, Bernoulli’s Eq.9.17: g(Zin − Zex) = g H = V2ex/2 ⇒ Vnozzle = 2gH d ρ dH −ρ [ AtankH] = ρAtank = Anozzle 2gH dt dt dH − Anozzle 1/2 = 2gH = −C H dt Atank Separate the variables − H 1/2 dH = −C dt Now integrate the equation from the beginning to the end of the process 1/2 1/2 2H1/2|end beg = 2H – 2H1 = −C (t – t1) To empty the tank we set the height at the end H = 0 and solve for time ∆t = t – t1 = 2 H1 2 H1 Atank Atank = = C Anozzle 2g Anozzle 5 ∆t = 0.007854 2 × 2.5 = 454.5 s = 7.6 min 9.81 2H1 g SONNTAG/BORGNAKKE STUDY PROBLEM 9-8 9.8 Stagnation point of a jet flow In a sand blast application we want to direct a jet flow towards a surface where the flow stagnates. The stagnation pressure should be at least 200 kPa. Find the velocity we need to create and the pump/compressor work required if we use a. liquid water or b. air. Both flows would be taken in at atmospheric conditions 100 kPa, 17oC. Solution: C.V. The pump/compressor, the pipe, the nozzle and the jet flow to the stagnation point. Steady state flow with no elevation changes and we will assume no heat transfer. We also will neglect the kinetic energy in the inlet flow and in the pipe flow and by definition the stagnation velocity is zero. Process: V1 = V2 = V4 = 0 , ÄZ = 0, assume reversible flow Energy Eq.6.13: h1 + win = h2 = h3 + 12V23 = h4 Entropy Eq.9.8: . s1 = s2 = s3 = s4 (Eq. is divided by m) States: 1: (T1, P1) 2: (h4, s1) 3: (P1, s1) sgen = 0 4: (Pstag, s1) We see that state 2 equals state 4 (same h and s), state 3 equals state 1, but with a V3 4 ⌡3 v dP Energy Eq. and Eq.9.13 win = h4 − h1 = 12V23 = h4 − h3 = ⌠ 2 3 4 1 a) Water: From Table A.4 (or B.1.1) ñ = 997 kg/m3 = 1/v ; incompressible 4 ⌡3 v dP = v (P4 – P3) = (200 – 100) / 997 = 0.1003 kJ/kg win = ⌠ V3 = 2win = 2∆P/ñ = 2000 × 0.1003 = 14.2 m/s Remark: This is rather low velocity for a water jet and an actual jet would use a much higher velocity and give a higher stagnation pressure. SONNTAG/BORGNAKKE b) STUDY PROBLEM 9-8 continued Air: Ideal gas: v1 = RT1/P1 = 0.287 × 290/100 = 0.8323 m3/kg Let us assume the flow is incompressible and do it as for water 4 ⌡3 v dP = v (P4 – P3) = 0.8323 (200 – 100) = 83.23 kJ/kg win = ⌠ V3 = 2win = 2∆P/ñ = 2000 × 24.97 = 408 m/s This is high velocity (120% of the speed of sound of about 340 m/s) Analyze with air as a compressible substance and find state 4: (Pstag, s1) Eq.8.32: T4 = T1 [Pstag / P1] (k-1)/k = 290.15 [200 / 100 ] 0.2857 = 353.69 K Now we get from the energy equation: win = h4 − h1 = Cp (T4 – T1) = 1.004 (353.69 – 290.15) = 63.79 kJ/kg and V3 = 2win = 2000 × 63.79 = 357 m/s Remark: Assuming incompressible flow is somewhat inaccurate as the specific volume used for calculating work is overestimated. SONNTAG/BORGNAKKE STUDY PROBLEM 9-9 9.9 A polytropic expansion process In a planned hydrogen storage facility an expander (turbine with heat transfer) brings 0.175 kg/s hydrogen gas from 1000 kPa, 550oC to 200 kPa. Assume the process is a polytropic process with n = 1.5. What are the work and heat transfer in the expander? Solution: . . CV: expander, steady single inlet and single exit flow with both W and Q. Energy Eq.6.13: hi + q = he + w ⌠e dq Entropy Eq.9.8: se – si = ⌡ + sgen i T Reversible polytropic process from Eq.8.37: i . P Te = Ti e Pi W exp . n-1 n 0.5 200 1.5 = 823.2 = 481 K 1000 e Q Work evaluated from Eq.9.19 -1.5 × 4.1243 ⌡vdP = − nR (Te − Ti) = w= − ⌠ (481 – 823.2) = 4231 kJ/kg n-1 0.5 . . W = mw = 0.175 × 4231 = 740 kW From the energy equation we have q = he – hi + w = Cp (Te – Ti) + w = 14.21 (481 – 823.2) + 4231 = –628.3 kJ/kg . . Q = mq = 0.175 × (−628.3) = -110 kW T P n = k = 1.409 i i n=1 e e n = 1.5 v n = 1.5 n=1 s SONNTAG/BORGNAKKE STUDY PROBLEM 9-10 9.10 The efficiency of an actual compressor The compressor in study problem 6.3 receives carbon dioxide at 100 kPa, 280 K, with a low velocity. At the compressor discharge, the carbon dioxide exits at 1100 kPa, 500 K, with a velocity of 25 m/s. The actual power input to the compressor is 50 kW. We want to find the isentropic efficiency and the total rate of entropy generation. Solution: C.V. Actual compressor, steady state, single inlet and exit flow. Energy Eq.6.13: q + h1 + 12V21 = h2 + 12V22 + w . . . Entropy Eq.9.8: ms1 + Sgen = ms2 Here we assume q ≅ 0 and V1 ≅ 0 so getting h from Table A.8 (25)2 -w = h2 - h1 + 12V22 = 401.52 - 198 + = 203.5 + 0.3 = 203.8 kJ/kg 2 × 1000 remember here to convert kinetic energy J/kg to kJ/kg by division with 1000. . . Wc -50 m= = = 0.245 kg/s w -203.8 . Solve for Sgen and use Eq.8.28 with the standard entropy from Table A.8 . . . Sgen = m (s2 – s1) = m [soT2 – soT1 – R ln( P2/P1 ) ] = 0.245 [ 5.3375 – 4.8034 – 0.1889 ln(11) ] = 0.02 kW/K C.V. Ideal (reversible) adiabatic compressor, exit state (2s) at 1100 kPa, but not 500 K. Energy Eq.6.13: h1 + 0 = h2s + 12V22 + ws Entropy Eq.9.8: s1 + 0 = s2s (Eq. divided by mass flow rate) Ideal exit state 2s: (P2, s = s1) same s as state 1 hence the name 2s P Eq.8.28: soT2s = soT1 + R ln( 2 ) = 4.8034 + 0.1889 ln(11) = 5.2564 kJ/kgK P1 Interpolate in Table A.8: T2s = 461.4 K and h2s = 363 kJ/kg Work from the energy equation becomes -ws = h2s + 12V22 – h1 = 363 + 0.3 – 198 = 165.3 kJ/kg w η = s = 165.3 = 0.81 Efficiency, Eq.9.28: w 203.5 SONNTAG/BORGNAKKE STUDY PROBLEM 9-11 st nd 9.11 A real steam turbine and its 1 and 2 law efficiencies A steam turbine receives steam at 2500 kPa, 500oC with an exhaust at 500 kPa, 300oC. We would like to find the first law isentropic efficiency, the specific reversible work, the specific irreversibility and the second law efficiency. Solution: C.V. The steam turbine. Steady flow, single flow and we assume adiabatic. Energy Eq.6.13: hi + 0 = he + w ⌠e dq Entropy Eq.9.8: se – si = ⌡ + sgen = sgen i T For the actual turbine we have the inlet and exit states so from steam tables B.1.3 Inlet: hi = 3462.04 kJ/kg , si = 7.3233 kJ/kg K Exit: he = 3064.2 kJ/kg , se = 7.4598 kJ/kg K The energy equation gives the actual work as wac = hi – he = 3462.04 – 3064.2 = 397.84 kJ/kg The first law isentropic efficiency is obtained by comparing the actual turbine work to that of a reversible adiabatic (thus isentropic) turbine with the same inlet state and the same exit pressure. This exit state has (P = 500 kPa, s = 7.3233 kJ/kg K) Exit isentropic: (P, s) Interpolate B.1.3: Te s = 263.9oC, he s = 2989.4 kJ/kg Now the isentropic turbine work is from the energy equation ws = hi – he s = 3462.04 – 2989.4 = 472.6 kJ/kg and the efficiency becomes ηT s = wac / ws = 397.84 = 0.842 472.6 The reversible work is from Eq.9.39 with no heat transfer (q = 0) and To = 298 K wrev = To(se – si) – (he – hi) = To(se – si) + wac = 298 (7.4598 – 7.3233) + 397.84 = 40.68 + 397.84 = 438.5 kJ/kg The irreversibility from Eq.9.40 i = wrev – wac = To(se – si) = qrev o = 40.68 kJ/kg which is also the reversible heat transfer in Eq.9.37. The second law efficiency is the actual work measured relative to the change in availability (which is also the reversible work) ηT II = wac / wrev = 397.84 / 438.5 = 0.907