SRM UNIVERSITY

advertisement

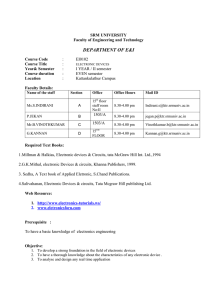

SRM UNIVERSITY Faculty of Engineering and Technology DEPARTMENT OF ICE Course Code Course Title Year& Semester Course duration Location : : : : : EI0 102/IC0102 ELECTRONICS DEVICES I YEAR / II semester EVEN semester Kattankulathur Campus Faculty Details: Name of the staff Section Office Office Hours Mail ID Ms.S.INDIRANI Hi tech 12.00-1.30 pm indh_2k3@yahoo.com Ms. S.INDIRANI Hi tech 12.00-1.30 pm indh_2k3@yahoo.com Required Text Books: 1.Millman & Halkias, Electronic devices & Circuits, tata McGraw Hill Int. Ltd.,1994 2.G.K.Mithal, electronic Devices & circuits, Khanna Publishers, 1999. 3. Sedha, A Text book of Applied Eletronic, S.Chand Publications. 4.Salivahanan, Electronic Devices & circuits, Tata Mcgraw Hill publishing Ltd. Web Resource: 1. www.electronichub.com 2. www.elctronicsforu.com Prerequisite : To have a basic knowledge of electronics engineering Objective: 1. To develop a strong foundation in the field of electronic devices 2. To have a thorough knowledge about the characteristics of any electronic device . 3. To analyse and design any real time application Tentative test details and portions: Cycle Test - I: Cycle Test –II: Model Exam: Unit I & II Unit III & IV All five units Assessment details Cycle test I Cycle test II Model test Surprise test Attendance TOTAL 10 marks 10 marks 20 marks 5marks 5 marks 50 marks Outcomes Students who have successfully completed this course Course outcome 1. To develop a strong foundation in the field of electronics 2.To understand the fundamental concepts of semiconductors 3.To logically analyse any electronic circuit 4.To apply the logic for any application in the electronic field. Program outcome 1. To understand the operation of intrinsic & extrinsic semiconductors. 2. To analyse the operation & characteristics of various diodes. 3. To analyse the construction & operation of BJT, FET & Thyristors. 4. To know the fabrication of IC’s. Detailed Session Plan Day DAY 1 Name of the topics UNIT-I: Fundamentals of Reference Millman & Halkias semiconductors DAY 2 DAY 3 DAY 4 DAY 5 DAY 6 Fermi Level Energy band diagram Generation & Recombination of carriers Intrinsic & extrinsic semiconductors DAY 7 DAY 8 DAY 9 DAY 10 DAY 11 Mobile charge carriers & Immobile ions Drift currents Diffusion currents Surprise Test- I UNIT II: Description & working of a Majority & minority charge carriers Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias PN diode DAY 12 Derivation of Diode equation Millman & Halkias DAY 13 DAY 14 DAY 15 DAY 16 DAY 17 Avalanche & zener breakdown Description of varactor diode Description of Tunnel diode Description of PIN diode Characteristics of photodiode ,photovoltaic cell & LDR Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias DAY 18 Characteristics of LED, Liquid crystal cell & seven segmental display Characteristics of opto couplers & laser diode Millman & Halkias DAY 19 DAY 20 DAY 21 DAY 22 DAY 23 DAY 24 DAY 25 DAY 26 DAY 27 DAY 28 DAY 29 DAY 30 DAY 31 DAY 32 DAY 33 DAY 34 DAY 35 DAY 36 DAY 37 DAY 38 DAY 39 DAY 40 DAY 41 DAY 42 DAY 43 DAY 44 DAY 45 DAY 46 DAY 47 DAY 48 Surprise Test-II UNIT III: Construction of a transistor Operation of a transistor in cutoff, active & saturation region. Input & output characteristics of CE configuration Input & output characteristics of CB configuration Input & output characteristics of CC configuration Evaluation of H parameters Hybrid model of a transistor under CE configuration Transistor as a switch Transistor as a heat sink UNIT IV: Operation of a JFET VA characteristics of JFET Small signal model of JFERT Operation of a MOSFET VA characteristics of MOSFET & Gate capacitance MOS as a charge transferring Device CCD, BBD Power MOSFET Unijunction Transistor Surprise Test-III UNIT V: Operation & VI char of SCR Operation & VI char of DIAC & TRIAC Operation & VI char of GTO Introduction to IC fabrication Fabrication of NMOS with Diffusion, Ion implantation & vapour deposition Fabrication of PMOS with Diffusion, Ion implantation & vapour deposition Fabrication of CMOS using Twin tub process CMOS Thick film Technology CMOS Thick film Technology Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias Millman & Halkias DAY 49 Revision