Effects of bonding parameters on the reliability performance of

advertisement

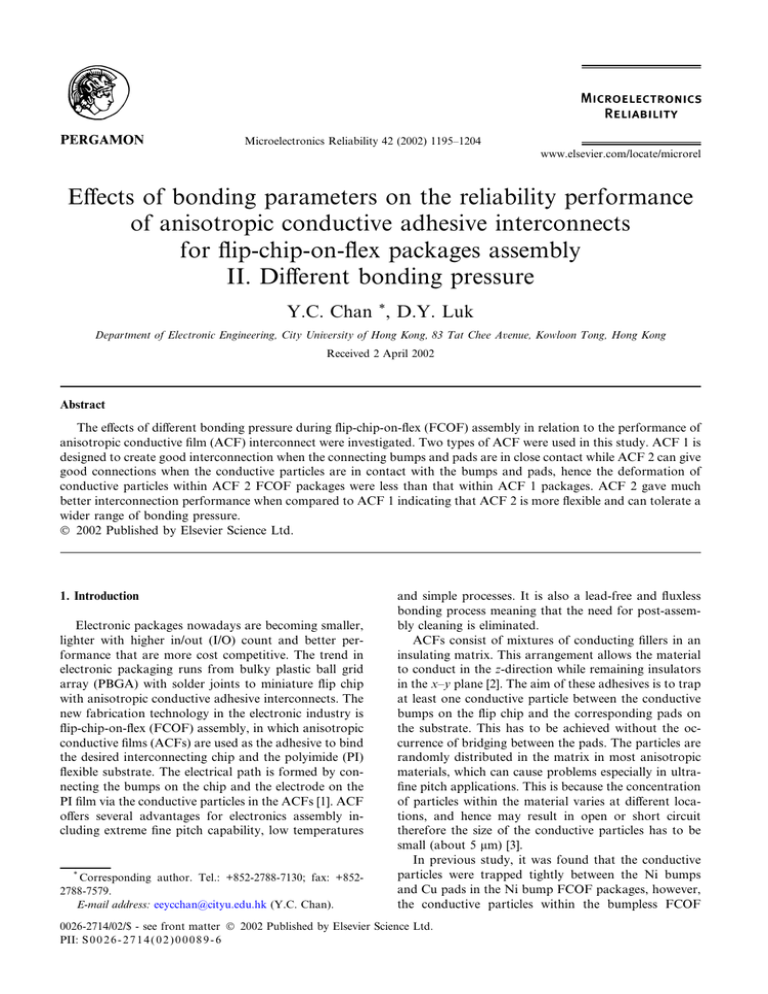

Microelectronics Reliability 42 (2002) 1195–1204 www.elsevier.com/locate/microrel Effects of bonding parameters on the reliability performance of anisotropic conductive adhesive interconnects for flip-chip-on-flex packages assembly II. Different bonding pressure Y.C. Chan *, D.Y. Luk Department of Electronic Engineering, City University of Hong Kong, 83 Tat Chee Avenue, Kowloon Tong, Hong Kong Received 2 April 2002 Abstract The effects of different bonding pressure during flip-chip-on-flex (FCOF) assembly in relation to the performance of anisotropic conductive film (ACF) interconnect were investigated. Two types of ACF were used in this study. ACF 1 is designed to create good interconnection when the connecting bumps and pads are in close contact while ACF 2 can give good connections when the conductive particles are in contact with the bumps and pads, hence the deformation of conductive particles within ACF 2 FCOF packages were less than that within ACF 1 packages. ACF 2 gave much better interconnection performance when compared to ACF 1 indicating that ACF 2 is more flexible and can tolerate a wider range of bonding pressure. Ó 2002 Published by Elsevier Science Ltd. 1. Introduction Electronic packages nowadays are becoming smaller, lighter with higher in/out (I/O) count and better performance that are more cost competitive. The trend in electronic packaging runs from bulky plastic ball grid array (PBGA) with solder joints to miniature flip chip with anisotropic conductive adhesive interconnects. The new fabrication technology in the electronic industry is flip-chip-on-flex (FCOF) assembly, in which anisotropic conductive films (ACFs) are used as the adhesive to bind the desired interconnecting chip and the polyimide (PI) flexible substrate. The electrical path is formed by connecting the bumps on the chip and the electrode on the PI film via the conductive particles in the ACFs [1]. ACF offers several advantages for electronics assembly including extreme fine pitch capability, low temperatures * Corresponding author. Tel.: +852-2788-7130; fax: +8522788-7579. E-mail address: eeycchan@cityu.edu.hk (Y.C. Chan). and simple processes. It is also a lead-free and fluxless bonding process meaning that the need for post-assembly cleaning is eliminated. ACFs consist of mixtures of conducting fillers in an insulating matrix. This arrangement allows the material to conduct in the z-direction while remaining insulators in the x–y plane [2]. The aim of these adhesives is to trap at least one conductive particle between the conductive bumps on the flip chip and the corresponding pads on the substrate. This has to be achieved without the occurrence of bridging between the pads. The particles are randomly distributed in the matrix in most anisotropic materials, which can cause problems especially in ultrafine pitch applications. This is because the concentration of particles within the material varies at different locations, and hence may result in open or short circuit therefore the size of the conductive particles has to be small (about 5 lm) [3]. In previous study, it was found that the conductive particles were trapped tightly between the Ni bumps and Cu pads in the Ni bump FCOF packages, however, the conductive particles within the bumpless FCOF 0026-2714/02/$ - see front matter Ó 2002 Published by Elsevier Science Ltd. PII: S 0 0 2 6 - 2 7 1 4 ( 0 2 ) 0 0 0 8 9 - 6 1196 Y.C. Chan, D.Y. Luk / Microelectronics Reliability 42 (2002) 1195–1204 packages were not fully compressed between the Al and Cu pads and hence leaving small gaps [4]. This finding was thought to be another factor that caused the ACF interconnects in bumpless FCOF packages to be less effective and may be influenced by the bonding pressure. The degree of spread of the conductive particles, determined by the amount of pressure applied during the bonding process, has a great influence on the contact resistance of the ACF joints. This is because if the particles are too spread out between adjacent bumps or pads, caused by too much pressure applied, they may end up contacting each other creating the same effect as short-circuiting; whereas if the bonding pressure is too low, the particles may not be able to make contact between the connecting bumps and pads. It is believed that the bonding pressure needed to compress the ACF before the conductive particles within will come into contact between the Al pads in bumpless chips and the pads on the flexible substrate is larger than that for chips with Ni bumps. With regard to bumpless chips, an ideal bonding force is not easy to obtain. Flip chips with Ni bumps create a surface with lands and grooves. This arrangement reduces the chance of adjacent conductive particles being bridged since they can be spread into the groove areas. The average diameter of a conductive particle is 3.50 lm and the bump height is about 4 lm hence, the conductive particles can be buried in the grooves escaping from causing bridges. However, bumpless chips have Al pads with bump height of only 1 lm meaning that the groove areas are too shallow to cater even a single conductive particle. This phenomenon is shown in Fig. 1. Since pressure is applied to force the conductive particles to make contact between the flip chip and flexible substrate, the degree of deformation of the conductive particles can affect the performance of ACF interconnects. Ideally, the conductive particles should be squashed until just before the metallic layers begin to break. At this point, the contact area between the bonding surfaces is the largest. However, if the pressure applied is too great, the metallic layers of the particles will burst open, exposing the polymer to the bonding surfaces, and hence would not be conductive. This phenomenon is shown in Fig. 2. This series of studies concentrate on the effects of different bonding parameters during the assembly of FCOF packages in relation to the reliability of the ACF joints. The aim of this study was to investigate the effects of different bonding pressure on the contact resistance of ACF joints. The results of this study would allow development of ACF joints using fine pitch flip chips on flexible substrates with better reliability and performance. 2. Experimental procedure The FCOF packages are made up of three different materials, namely silicon (Si) chip, ACF and flexible substrate. 2.1. Silicon chips Fig. 1. Schematic showing the possibility of creating bridging in (a) Ni bump and (b) bumpless FCOF packages (the shape of the conductive particles is also different depending of their locations within the ACF matrix; oval between connection bumps and pads but spherical between adjacent bumps or pads). The dimensions of the silicon (Si) chips are 10:87 3:14 mm2 , with rectangular bumps (70 50 lm). The bumps are arranged in sets of five as a group; with two adjacent bumps for measuring insulation resistance and three for contact resistance. There are a total of twelve sets of these daisy-chained bumps within the chip. The layout of the chip is shown in Fig. 3. Fig. 2. Conductive particle with (a) minimum contact and (b) maximum contact with the bump and pad and (c) too much pressure causing the particle to burst open. Y.C. Chan, D.Y. Luk / Microelectronics Reliability 42 (2002) 1195–1204 1197 Fig. 3. Schematic showing a corner of a Si chip with daisy-chained bumps. Electroless nickel (Ni) bumping process involves aluminium (Al) cleaning, Al activation, electroless Ni deposition and immersion gold (Au) coating [2]. The bump height of the Ni bump and Al pad are 4 and 1 lm, respectively. The last two steps in the bumping process of bumpless chips were omitted. to prevent electrical conduction of adjacent conductive particles in the x- and y-direction, and it is designed to become soft when subjected to thermal compression during bonding. Fig. 4 shows the structure of the two types of ACF and their specifications are summarized in Table 1. 2.2. ACFs 2.3. Flexible substrate Two types of ACF were used in this study in order to compare their flexibility with different bonding parameters. ACF 1 is a double layer ACF that consists of an epoxy layer and another one filled with conductive and insulation particles. The conductive particles of ACF 1 are polymer spheres plated with a thin layer of nickel followed by a thin layer of gold. ACF 2 is a single layer ACF that consists of an epoxy layer filled with conductive particles. The conductive particles of ACF 2 are polymer spheres plated with a thin layer of nickel followed by a thin layer of gold with an additional insulation layer. The purpose of the insulation layer is The flex substrates used in this study were about 40 lm thick and the electrode is gold/electroless nickel coated copper (Au/Ni/Cu). 12 lm thick of copper (Cu) traces was electro-deposited onto a 25 lm thick PI, followed by 4–5 lm thick of electroless nickel (Ni) and finally sputtered with a 0.4 lm thick gold (Au) layer. Since the flex substrate is of ultra-fine pitch (the smallest gap between the traces was 10 lm), Ni was plated onto the Cu traces to prevent Cu migration. Au sputtering was necessary to prevent the Ni layer from oxidation. During the pre-bonding process, the ACF was laminated onto the flexible substrates, by using the Karl Suss Fig. 4. Schematic showing the structure of (a) ACF 1 and (b) ACF 2 and their conductive particles. 1198 Y.C. Chan, D.Y. Luk / Microelectronics Reliability 42 (2002) 1195–1204 Table 1 Specifications of the ACF Description Film thickness (lm) Conductive particle Insulation coated Particle size (lm) Pre-bonding temperature (°C) Pre-bonding time (s) Pre-bonding force (MPa) per unit area of bump Bonding temperature (°C) Bonding time (s) Bonding force (N) a Specification ACF 1 ACF 2 30 Au/Ni coated polymer No 3.5 90 30 Au/Ni coated polymer Yes 3.5 90 5 10 5 10 200a 10 60 190a 10 60 Selected according to our other research [4]. manual flip chip bonder. The final bonding of flip chip onto the ACF/flex was carried out using the Toray semiautomatic flip chip bonder. The alignment accuracy is 2 lm. Different bonding pressures were used in this study, as shown in Table 2 and the schematics of the bonding process is shown in Fig. 5. The contact resistance of the ACF joints of the FCOF packages was measured by using the four-point probe method as shown in Fig. 6. In the four-point probe test, 1 mA was applied to the circuit constantly and the voltage was measured for each set of bumps using the Hewlett Packard 3478A Multimeter. The contact resistance was calculated by using R ¼ V =I. The samples were moisture-soaked under 85 °C/ 85%RH conditions for 336 h and the contact resistance was measured again. The samples were then mounted in epoxy resin and cross-sectioned. The Philips XL40 FEG scanning electron microscope (SEM) equipped with energy dispersive X-ray (EDX) was used to inspect and analyse the microstructure and microjoints of the FCOF packages, especially the chip/conductive particle metallization interface. Dimensions of the conductive particles were also measured. 3. Results and discussion Table 2 Bonding pressure used Bonding pressure (N) Standard Tests Fig. 6. Contact resistance measurement of ACF joints using the four-point probe method (I ¼ 1 mA). 60 70, 80, 90, 100, 110, 120, 130 From Fig. 7, one can see that the FCOF packages with different types of ACF behaved differently. Packages with ACF 2 showed very steady interconnection regardless of the bonding pressure whereas those with Fig. 5. Schematic showing the formation of flip chip interconnections with (a) bumped chip and (b) bumpless chip using ACFs. Y.C. Chan, D.Y. Luk / Microelectronics Reliability 42 (2002) 1195–1204 1199 Fig. 7. Average contact resistance of Ni bumps and bumpless packages with ACF 1 and ACF 2 assembled at various pressures (a) before and (b) after ageing. ACF 1 gave fluctuating joints’ performance. In general, the contact resistance of the FCOF packages with ACF 1 decreased dramatically then increased steadily whereas those with ACF 2, more or less, stayed the same. For FCOF packages with Ni bump/ACF 1 bonded at 60–70 N, the contact resistance decreased from 28.8 to 13.3 mX but then increased systematically when the bonding pressure was above 70 N. The contact resistance of the bumpless/ACF 1 packages decreased from 38.5 to 20.4 mX when bonded at 60–80 N but then increased with diligence when the bonding pressure used was above 80 N. By looking at the contact resistance obtained when ACF 1 was used as the connecting material, FCOF packages with Ni bump assembled at 70 N and bumpless packages assembled at 80 N gave the best contact, with initial average contact resistance 13.3 and 20.0 mX, respectively. For ACF 2, packages with Ni bumps and bumpless packages gave best interconnections at 80 and 100 N respectively, with initial average contact resistance of 1.07 and 4.11 mX, respectively. The contact resistance of the packages increased slightly after being moisture soaked under 85=85 con- ditions, with the Ni bump/ACF 2 FCOF packages increased the least. Humid environments favour oxidation of the Al pads and hence the bumpless packages gave higher contact resistance after the moisture soak test. The contact resistance of the packages with Ni bumps did not increase much due to the thin layer of gold sputtered on top therefore the Ni bumps are less prone to oxidation. The addition of oxide layer is thought to impede the flow of electrons through the connecting bump-conductive particle-pad path [4]. When pressure is applied, the conductive particles within the ACF would experience certain amount of compressive force. As a result, the conductive particles would change from being spherical to oval, with the length in the x-direction being greater than that in the y-direction. This phenomenon is shown in Fig. 8. Conductive particles that are caught in between the connecting bumps and pads tend to be oval while the ones not being trapped remains spherical, as shown in Fig. 1. During the bonding process, the ACF is being compressed thermally and the conductive particles are sandwiched between the connecting bumps and pads. As a 1200 Y.C. Chan, D.Y. Luk / Microelectronics Reliability 42 (2002) 1195–1204 Fig. 8. Schematic showing the change in shape and dimensions of a conductive particle after pressure was applied during bonding (x1 and y1 represents length in x- and y-direction before bonding respectively; x2 and y2 represents length in x- and y-direction after bonding, respectively). result, the particles ‘‘shrunk’’ in the y-direction and ‘‘grown’’ in the x-direction. According to the specifications given by the manufacturer, the average diameter of the conductive particles within ACF 1 and ACF 2 is 3.50 lm. The optimal bonding pressure needed to create best interconnections was different when using different types of flip chip and ACF, as summarized in Table 3. The average dimensions of the conductive particles within the different combinations of FCOF packages, assembled at their ideal bonding pressure, are shown in Table 4. The conductive particles within the Ni bump/ ACF 1 and bumpless/ACF 1 packages after the bonding process changed to (4.56, 1.53 lm) and (4.31, 2.06 lm), respectively. The average dimensions of the conductive particles changed to (4.52, 1.42 lm) and (4.37, 1.92 lm) for Ni bump/ACF 2 and bumpless/ACF 2 packages, respectively. The bonding pressure applied during assembly of FCOF packages affects the deformation of the conductive particles within the ACF, which in turn affects the performance of the interconnects. The optimal pressure needed to compress the ACF during bonding should squash the conductive particles until just before the Table 3 Ideal bonding pressure needed to create the best interconnections with different types of ACF and flip chip Fig. 9. SEM micrograph showing the ideal shape of a conductive particle with largest surface area in contact with the connection bump and pad. outermost layer of coating breaks, as shown in Fig. 9. This amount of pressure should create a maximum surface area of conductive particles in contact with the connecting bumps and pads therefore a larger volume for electrons to flow through the bump-conductive particle-pad path. However, if the pressure applied is greater than the outermost layer of the conductive Ideal bonding pressure (N) Ni bump Bumpless ACF 1 ACF 2 70 80 80 100 Table 4 Dimensions of the conductive particles within different FCOF packages after bonding with their ideal bonding pressure (initial diameter of a conductive particle ¼ 3:50 lm) Dimensions (lm) ACF 1 Ni bump Bumpless ACF 2 x y x y 4.56 4.31 1.53 2.06 4.52 4.37 1.42 1.92 Fig. 10. SEM micrograph showing the broken outermost layer of the conductive particle exposing part of the polymer sphere. Y.C. Chan, D.Y. Luk / Microelectronics Reliability 42 (2002) 1195–1204 particle can withstand (metallic coating in ACF 1 and insulation layer in ACF 2 particles), the conductive particle may burst open, exposing the polymer sphere, which is an insulator, to the connecting bump and pad. Hence, the conductive property of the particle is lost, leaving it to be an insulator that acts as an obstacle impeding the electrons from trying to flow through the connecting bump and pad. During the bonding process, the ACF is being cured and flows. The flow of ACF provided the conductive particles with sufficient mobility to distribute themselves evenly between the bumps and pads [4]. During their 1201 travel through the ACF matrix, friction is generated [5] and the outermost layer of the conductive particle might be rubbed off, as shown in Fig. 10. As a result, the performance of the interconnects may be different even if the same number and size of conductive particles were present. The function of the insulation layer of ACF 2 conductive particles is to prevent electrical conduction in the x- and y-direction between adjacent particles, and it is designed to become soft and breaks when subjected to thermal compression during bonding. However, this additional layer may serve another purpose. Theoretically, having three layers covering the polymer core Fig. 11. SEM micrographs showing the deformation of conductive particles within the Ni bump/ACF 2 packages assembled at (a) 70 N (b) 80 N (c) 90 N (d) 100 N and (e) 110 N, with a combination of trapped conductive particles with intact and incomplete outermost layers. 1202 Y.C. Chan, D.Y. Luk / Microelectronics Reliability 42 (2002) 1195–1204 should be better than two layers. This is because the insulation layer of the conductive particles in ACF 2 can act as a friction-proof layer making it difficult to rub off the two inner metallic layers. Without the third layer for protection, the metallic coatings on the polymer spheres in ACF 1 are easily removed during the travel through the ACF matrix when compared to ACF 2 and hence unable to maintain their conductive properties when reached between the connecting bumps and pads. Referring to Figs. 11 and 12, at least one conductive particle was able to distribute itself in between the connecting bumps and pads. However, the degree of their deformation and the completeness of their outer- most layer were different. This could be one of the reasons why certain amount of pressure applied can result in interconnects with lower contact resistance. In Fig. 11(a), the conductive particles were not compressed enough leaving the connecting bumps and pads in contact with only part of their surface, which is not enough to give the best contact. In contrast, the conductive particles in Fig. 11(c) and (d) were compressed too much and their outermost layer was broken. The conductive particle in Fig. 11(e) was deformed too much and its conductive property might be lost. In Fig. 11(b), when 80 N was applied during the assembly of the FCOF package, the conductive particles were being compressed Fig. 12. SEM micrographs showing the deformation of conductive particles within the bumpless/ACF 2 packages assembled at (a) 70 N (b) 80 N (c) 90 N (d) 100 N (e) 110 N and (f) 120 N, with a combination of trapped conductive particles with intact and incomplete outermost layers. Y.C. Chan, D.Y. Luk / Microelectronics Reliability 42 (2002) 1195–1204 Fig. 13. SEM micrograph showing a conductive particle pushed into the aluminium oxide layer on the Al pad. and deformed in the desirable manner, with their surfaces in contact with the bump and pad at maximum, hence resulting in lowest contact resistance and therefore gave the best interconnection. In general, one would expect the more pressure applied the more deform the particles would be as the gap between the chip bump and substrate pad becomes smaller. This assumption is seen with the FCOF packages with Ni bumps (Fig. 11), however, the dimensions of the conductive particles and the gap between the connecting bumps and pads seem to be unaffected by the bonding pressure in bumpless FCOF packages (Fig. 12). Previous study showed that the Al pad is made up of two layers, namely the Al pad itself and a layer of aluminium oxide [4]. Aluminium oxide is a softer material with respect to nickel. When the conductive particles were subjected to compression during bonding, the layer of aluminium oxide was acting like a ‘‘soft’’ sponge allowing the conductive particles to embed in it. In this way, part of the pressure applied to the interconnects was absorbed by the oxide layer, which in turn compressing less onto the conductive particles. However, the distance the conductive particles can travel into the oxide layer is abruptly stopped when they reach the oxide/Al pad interface, and at this point, deformation of the conductive particles begins due to the absence of ‘‘shock absorbent’’, as shown in Fig. 13. This observation was not found in Ni bump packages since the conductive particles were unable to push into nickel and also absent in ACF 1 FCOF packages due to the narrower working window of ACF 1 and its sensitivity to different pressure. 4. Conclusions By correlating the results obtained from contact resistance measurement and change in dimensions of the 1203 conductive particles, the most suitable bonding pressure for different combinations of the types of ACF and flip chip used can be determined. For ACF 1, Ni bump and bumpless packages performed best when 70 and 80 N pressure was applied, respectively; whereas for ACF 2, packages gave the best contact when 80 and 100 N was applied to Ni bump and bumpless packages, respectively. ACF 2 gave much better interconnection performance when compared to ACF 1 indicating that ACF 2 is more flexible and can tolerate a wider range of bonding pressure. However, the pressure required to assemble FCOF packages with ACF 2 is higher than that for ACF 1. This means that expenses of the companies may increase but in return with higher yield of products that would perform better and are more reliable. In addition, the presence of the extra insulation coating on the ACF 2 conductive particles may act as a friction-proof layer, protecting the two inner metallic layers from being rubbed off during their travel through the ACF matrix, hence retaining their conductive properties when reached in between the connecting bumps and pads. The performance of the ACF interconnects greatly depends on the deformation of the conductive particles. It is difficult to establish how much the conductive particles should deform in order to create the best interconnections. It is equally hard to judge to what dimensions the conductive particles should reach during the bonding process since their initial size varies slightly. However, by looking at the measurement of the conductive particles, we conclude that the change in dimensions should reach about 30% in the x-direction and about 50% in the y-direction when ACF 1 is used. Since ACF 1 is designed to create good interconnection when the connecting bumps and pads are in close contact while ACF 2 can give good connections when the conductive particles are in contact with the bumps and pads, the change in dimensions of the conductive particles for ACF 2 is smaller when compared to that of ACF 1. Hence, for best performance of the interconnects when ACF 2 is used, 25% change in the x-direction and 40% change in the y-direction should be achieved. Although the presence of aluminium oxide in bumpless FCOF packages may impede the flow of electrons through the interconnecting bumps and pads and hence creating poorer interconnections, it may also act as a ‘‘shock absorbent’’ preventing the conductive particles from experiencing too much pressure during bonding. This explains why the dimensions of the conductive particles within bumpless/ACF 2 FCOF packages did not alter much when different pressure was applied. Simply by looking into changing the bonding pressure alone cannot produce the highest yield of interconnects, all the parameters should be coupled together in order to create best performance. This series of study that concentrates on investigating the affects of bonding temperature and pressure have provided fundamental 1204 Y.C. Chan, D.Y. Luk / Microelectronics Reliability 42 (2002) 1195–1204 understanding of how ACF behaves under different bonding conditions. Acknowledgements The authors would like to acknowledge the Strategic Research Grants (Project no. 7001080) of the City University of Hong Kong. References [1] Chang SM, Jou JH, Hsieh A, Chen TH, Chang CY, Wang YH, et al. Characteristic study of anisotropic conductive film for chip-on-film packaging. Microelectron Reliab 2001; 41:2001–9. [2] Aschenbrenner R, Ostmann A, Motulla G, Zakel E, Reichl H. Flip chip attachment using anisotropic conductive adhesives and electroless nickel bumps. IEEE Trans CPMT–– Part C 1997;20(2):96. [3] Sarkar G, Mridha S, Tan TC, Wu YT, Sem CK. Flip chip interconnect using anisotropic conductive adhesive. J Mater Proc Tech 1999;89–90:484–90. [4] Chan YC, Luk DY. Effects of bonding parameters on the reliability performance of anisotropic conductive adhesive interconnects for flip-chip-on-flex (FCOF) packages assembly: I. Different bonding temperature. Microelectron Reliab 2002;42:1185–94. [5] Chiu YW, Chan YC, and Lui SM. Electric field effects on short-circuiting between adjacent joints in fine pitch anisotropically conductive adhesive interconnects. 52nd Electronic Components and Technology Conference, San Diego, California, USA, May 2002.