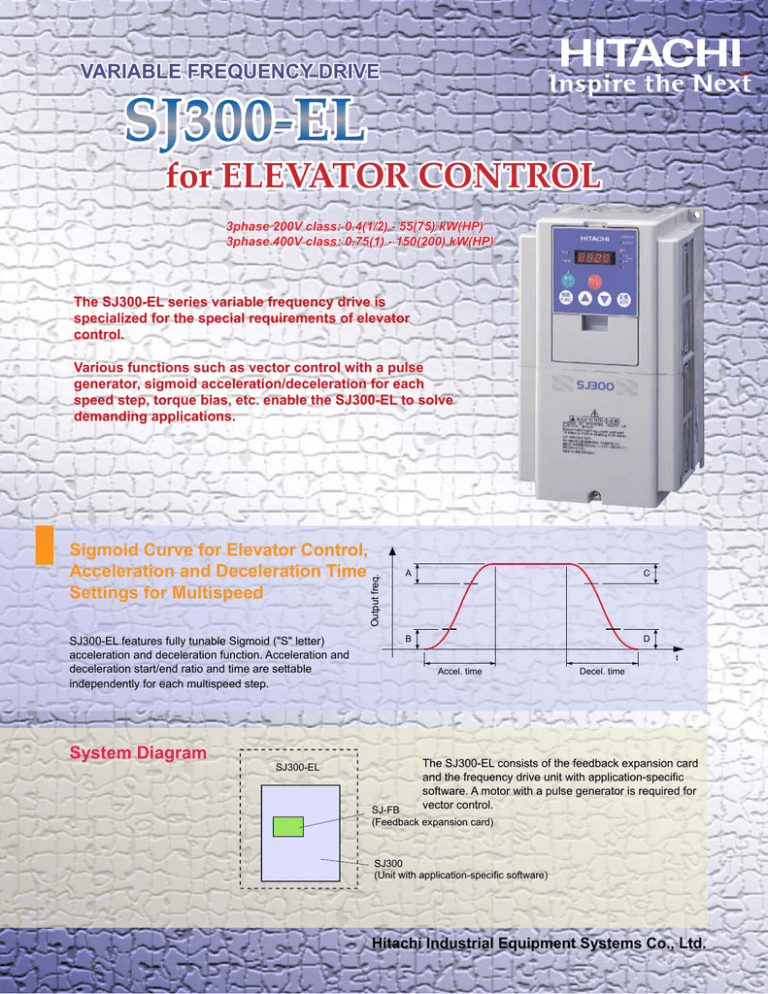

for ELEVATOR CONTROL - Hitachi America, Ltd.

advertisement

VARIABLE FREQUENCY DRIVE for ELEVATOR CONTROL 3phase 200V class: 0.4(1/2) - 55(75) kW(HP) 3phase 400V class: 0.75(1) - 150(200) kW(HP) The SJ300-EL series variable frequency drive is specialized for the special requirements of elevator control. Sigmoid Curve for Elevator Control, Acceleration and Deceleration Time Settings for Multispeed SJ300-EL features fully tunable Sigmoid ("S" letter) acceleration and deceleration function. Acceleration and deceleration start/end ratio and time are settable independently for each multispeed step. System Diagram SJ300-EL Output freq. Various functions such as vector control with a pulse generator, sigmoid acceleration/deceleration for each speed step, torque bias, etc. enable the SJ300-EL to solve demanding applications. A C B D t Accel. time Decel. time The SJ300-EL consists of the feedback expansion card and the frequency drive unit with application-specific software. A motor with a pulse generator is required for vector control. SJ-FB (Feedback expansion card) SJ300 (Unit with application-specific software) Hitachi Industrial Equipment Systems Co., Ltd. Gain Adjustment 100% ASR gain [%] Variable ASR* gain setting function is available. Stable operation is obtained with high-gain setting at stopping or slow speed, low-gain at high-speed steady run. Settable up to eight points. *ASR: Automatic Speed Regulator f1 f2 f3 f4 f5 f6 f7 Torque Bias Function Output frequency f8 Load cell The SJ300-EL controls starting torque with feedback signal from the load cell. For smoother elevator move! IM PG SJ300-EL Counter weight Cargo Flexible Brake Control Signal Setting Flexible adjustment is available for brake control. Braking frequency and release frequency are independently settable. wait Brake confirm wait Delay Acc. wait Brake confirm wait Stop wait Output frequency Forward [FW] Brake Release [BRK] Brake Confirm [BOK] Battery-backup for Power Failure (customized specification) In case of power failure, the SJ300-EL can continue operation with battery or UPS. Please provide specifications of battery or UPS to Hitachi for review. Emergency Control In case of a malfunction of pulse generator, the SJ300-EL automatically changes control method from vector control to SLV or V/f and continues operation. Standard Specifications Power source Output frequency range Control method Starting torque Overload capacity Acc./decel. time Protective functions Ambient temp perature Humidityy Location 3-phase 200-230V+/-10% or 380-480V +/-10%, 50/60Hz +/-5% 0.1-400Hz Sine-wave pulse width modulation (PWM) control 200(180)*% at 0.5Hz, 150% or at around 0Hz, 100% at 0Hz 150%, 60sec/ 200(180)*%, 0.5sec. 0.01-3,600sec. for each multispeed step Over-current, overload, braking resistor overload, over-voltage, EEPROM error, under-voltage error, CT (Current transformer) error, CPU error, external trip, USP error, ground fault, input over-voltage, instantaneous power failure, expansion card 1 error, expansion card 2 error, inverter thermal trip, phase failure detection, IGBT error, thermistor error -10 to 50 deg gree C 25 to 90% RH Altitude 1,000m or less, indoors (no corrosive gas nor dust)) Dimensions SJ300- [Unit: mm(inch)] (inches for reference only) HFEEL LFUEL HFUEL Width Height Depth Model Configuration (kW) (HP) 007,015,022,040,055 004,007,015,022,037,055 007,015,022,040,055 150((5.91)) 255(10.04) 140(5.51)*2 075,110 075,110 075,110 210((8.27)) 260(10.24) 170(6.69)*4 150,185,220 300 370,450,550 750,900 1100,1320 150,185,220 300 370,450 550 150,185,220 300 370,450,550 750,900 1100,1500 250((9.84)) 310((12.20)) 390((15.35)) 480((18.90)) 390((15.34)) 480((18.90)) 390(15.35) 540(21.26)*1 550(21.65)*2 700(27.56)*3 700(27.56) 740(29.13) 190(7.48)*4 195(7.68)*4 250(9.84)*4 250(9.84)*4 270(10.63)*4 270(10.63)*4 0.4 0.75 1.5 2.2 3.7 5.5 7.5 11 2 3 5 7.5 10 15 1/2 1 15 18.5 22 20 25 30 30 40 37 50 45 60 55 75 90 110 132 150*5 75 100 125 150 175 200 200V class 400V class *75kW or greater *1:Add 100mm(3.94in.) for conduit box *2: Add 80mm(3.15in.) for conduit box *3: Add 70mm(2.76in.) for conduit box *4:Add 8.5mm(0.33in.) for potentiometer *5:UL Version only, rated current is same as 132kW. Information in this brochure is subj b ect to change without notice. SIG-056 2003.12