EXPERIMENT:01 Aim: Constructional study of DC Machine Parts

advertisement

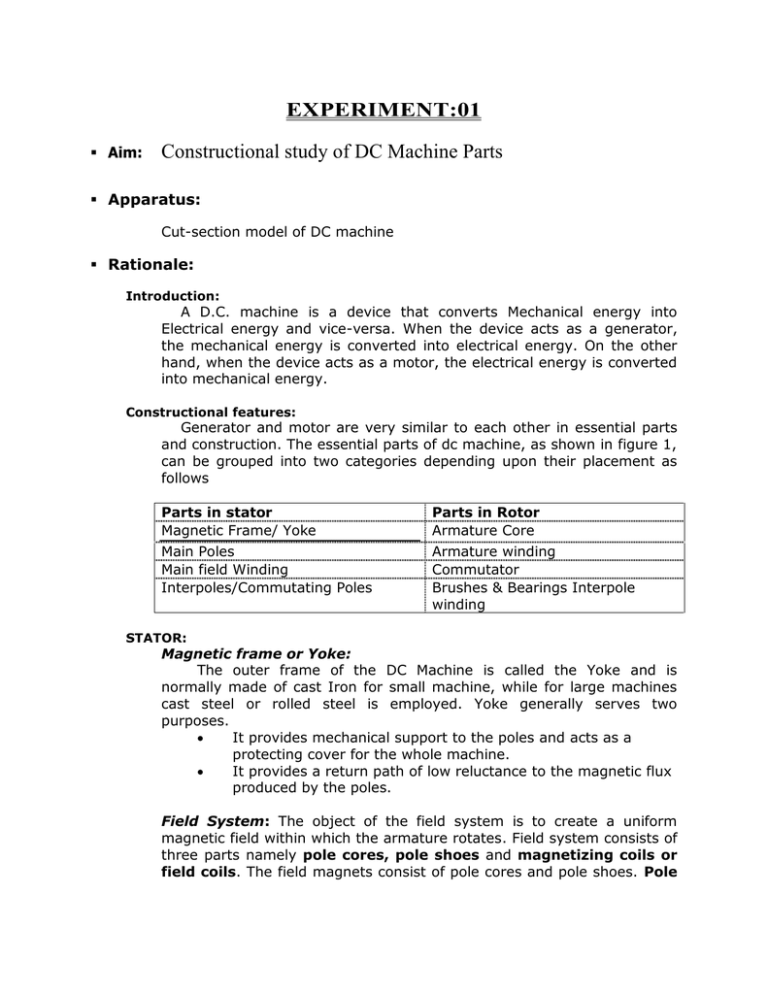

EXPERIMENT:01 Aim: Constructional study of DC Machine Parts Apparatus: Cut-section model of DC machine Rationale: Introduction: A D.C. machine is a device that converts Mechanical energy into Electrical energy and vice-versa. When the device acts as a generator, the mechanical energy is converted into electrical energy. On the other hand, when the device acts as a motor, the electrical energy is converted into mechanical energy. Constructional features: Generator and motor are very similar to each other in essential parts and construction. The essential parts of dc machine, as shown in figure 1, can be grouped into two categories depending upon their placement as follows Parts in stator Magnetic Frame/ Yoke Parts in Rotor Armature Core Main Poles Main field Winding Interpoles/Commutating Poles Armature winding Commutator Brushes & Bearings Interpole winding STATOR: Magnetic frame or Yoke: The outer frame of the DC Machine is called the Yoke and is normally made of cast Iron for small machine, while for large machines cast steel or rolled steel is employed. Yoke generally serves two purposes. It provides mechanical support to the poles and acts as a protecting cover for the whole machine. It provides a return path of low reluctance to the magnetic flux produced by the poles. Field System: The object of the field system is to create a uniform magnetic field within which the armature rotates. Field system consists of three parts namely pole cores, pole shoes and magnetizing coils or field coils. The field magnets consist of pole cores and pole shoes. Pole core is usually of circular section & is used to carry the coils of insulated wires carrying the exciting current. Pole shoe acts as a support to the field coils & spread out the flux in the air gap & also being a larger cross-section reduces the reluctance of the magnetic path. Both pole cores and pole shoes are laminated and are bolted to the frame of yoke. The thickness of the lamination varies from 1mm to 0.25mm Field coils or field windings, which consists of copper wire or strip wound around the pole pieces. When current passes through the coil, the coil magnetizes the poles, which produce the necessary flux that is cut by revolving armature conductors. Interpoles & Interpole Winding: These poles are comparatively smaller in size than the main poles. They are placed between adjacent main poles. The flux provided by interpoles gives spark-less commutation & hence they are also called as commutating poles. The exciting coils around Interpoles is normally connected in series with the armature circuit & carries the entire armature current. Air gap: Radial spacing between main pole & surface of the armature is called air-gap. The length of air gap may be set between 1mm & 5mm. ROTOR: Armature: The purpose of armature is to rotate the armature conductors in the uniform magnetic field. It is further divided into two parts namely: Armature core and Armature winding. Armature core: it is cylindrical in shape mounted on the shaft as shown in figure 2. It consists of slots on its periphery & the air ducts to permit the air flow through armature which serves cooling purpose It is made from high permeability silicon-steel stampings, each stamping being separated from its neighboring one by thin paper or varnish as insulation. The function of armature core is: To provide house for armature winding To provide a path of low reluctance to the magnetic flux produced by the field winding Armature winding: It is nothing but the interconnection of the armature conductors placed in the slots provided on the armature core periphery. The function of armature winding is: To generate e.m.f in the armature winding in case of generator To carry the current supplied in case of dc motor Commutator: The basic nature of e.m.f induced in the armature conductor is alternating. This needs rectification in case of d.c. generator, which is possible by device called as commutator. It is cylindrical in shape and is made up of wedge shape segment of hard drawn, High conductivity copper. These segments are insulated from each other by thin layer of mica as shown in figure 3. It is connected to the armature conductor by means of copper lug or strip. The function of commutator is: To collect current from the armature conductors To convert internally developed alternately e.m.f into unidirectional e.m.f. Brushes: The function of brushes is to collect current from commutator or to drawn current to commutator. They are usually made of carbon and are in the shape of rectangular block. These brushes are housed in brush holders usually of the box type as shown in the fig. The brushes are in contact with the commutor by a spring whose tension can be adjusted by changing the position of lever in the notches. Bearings: Bearing is a device, which gives free & smooth rotation of armature. Ball bearing is frequently employed due to their reliability, though for heavy duties roller bearings are preferable.