PDF - Fiscalini Farms Methane Capture Project

advertisement

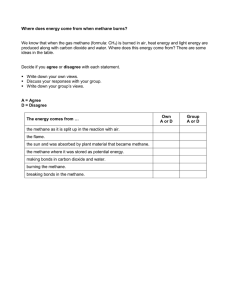

Fiscalini Farms Methane Capture Project The project, located at Fiscalini Dairy Farms in Modesto, California, is one of very few in the state operating an anaerobic digester system to capture methane gas created from the farm’s cow manure. The project is being verified to a Climate Action Reserve (CAR) protocol. Emission Reductions: Fiscalini Farms contains approximately 1500 cows, producing about 100 pounds of manure a day and large quantities of methane gas as a result. Methane has a global warming potential 21 times more potent than CO2. Therefore the capture and destruction of this gas has significant impact on reducing greenhouse gas (GHG) emissions. The project uses two anaerobic digester tanks to manage the waste and prevent the release of methane. Prior to the digester installation, manure was flushed from the freestall barns and sent to an uncovered anaerobic lagoon where methane gas was released into the atmosphere. The farm helps mitigate GHG emissions further by generating renewable electricity and heat from the captured methane through a combined heat and power (CHP) generation system. This recycles heat back to the digester and supplies enough electricity for the farm’s entire operations in addition to selling to the local grid. However, these C02e emission reductions are not included in the project calculations. producing methane inside the tanks. The methane is then piped out of the digesters to a 710 kW CHP generator system. The electricity is used by Fiscalini Farms dairy operations, Fiscalini Cheese Company’s cheese making facility (which produces 500,000 pounds of raw-milk aged cheese per year), and the local grid; while the heat, in the form of hot water, is sent back to the digester tanks to keep them operating at 100 degrees. The hot water is additionally used for sanitation needs at the dairy farm and cheese facility as well as for the pasteurisation process in the cheese plant. In addition to the emission reductions, the digesters also produce a valuable by-product; a portion of the effluent is removed from the tanks daily and separated into liquid and solid components. The liquid portion is used as the only source of fertiliser for the farm’s crops while some of the solid portion is used as bedding for the livestock. There is a plan to sell the remainder as a peat moss substitute to local nurseries and turf grass growers. About the project: The project consists of two 86 ft diameter digester tanks that can hold approximately 860,000 gallons of effluent each. In addition to the manure, the project also sends waste whey produced from the on-site cheese production and silage from the farm to the digesters. The tanks are heated to approximately 100 degrees Fahrenheit to help facilitate the bacteria breaking down the particles and subsequently The CarbonNeutral Company - a world-leading provider of carbon reduction solutions London T: +44 20 7833 6000 E: sales@carbonneutral.com New York T: 1-646-367-5800 E: salesna@carbonneutral.com Singapore T: + 65 688 44465 E: salesasia@carbonneutral.com www.carbonneutral.com About agricultural methane biogas: Project area coordinates: Latitude 37° 70’ 86’ N and longitude - 121° 12’ 96’ W About the region: A leader in the US with regard to environmental policy, California has the most aggressive renewable energy requirement in the country, with a Renewables Portfolio Standard (RPS) of 33%, requiring utilities to supply at least a third of electricity from renewable sources by 2020. The state has also set the bar high with stringent air quality regulations. California leads the nation in dairy farming with some 2,700 farms. However, despite the GHG benefits from these methane capture projects, less than one percent of these farms are operating digesters, due in large part to the strict air quality regulations, which don’t exist to the same extent elsewhere. Fiscalini Farms has made additional investments to its digester system to make sure that it is compliant with the local air quality authority in addressing non greenhouse gasses such as NOx emissions - formed anywhere there is combustion. There are numerous opportunities for digester The CarbonNeutral Company - a world-leading provider of carbon reduction solutions London T: +44 20 7833 6000 E: sales@carbonneutral.com New York T: 1-646-367-5800 E: salesna@carbonneutral.com Singapore T: + 65 688 44465 E: salesasia@carbonneutral.com Globally, livestock manure contributes roughly five per cent of total anthropogenic (human induced) methane emissions. Methane is produced and emitted during the decomposition of organic material in livestock manure. Three groups of animals - swine, dairy and non-dairy cattle - account for 80% of methane from livestock. Methane released from manure management systems can be captured using an anaerobic digester. These digesters are air tight, oxygen-free containers which organic material like animal manure and food scraps are fed into. Naturally occurring bacteria in the organic waste breaks it down to produce methane gas - commonly known as biogas – along with an odour-reduced effluent. Using generators, this gas can then be converted into electricity (and/or heat) which delivers a twofold environmental benefit: it reduces the volume of methane released into the atmosphere and displaces electricity which would otherwise have been drawn primarily from fossil fuel sources. expansion in the state if the regulatory requirements can be met; Fiscalini Farms sets the example for future methane capture projects in California that will hopefully encourage development at a rate required for commercial viability of the industry. www.carbonneutral.com