Effects of the Baking Temperature and Time on the Quality of Biscuits

advertisement

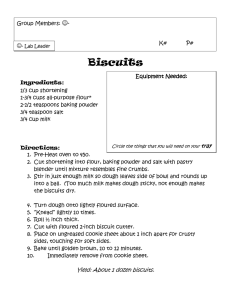

Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 Effects of the Baking Temperature and Time on the Quality of Biscuits Anis Alam Siddiqui1 and Lubna Nasreen2 Abstract: Baking is obviously one of the most important stages of biscuits production. Baking time and oven temperature have greatest effects on biscuit quality. Several studies have shown that the physical properties of dough and the recipe of biscuit making depend on the type of biscuit and the methods used in dough formation. The aim of this study was to investigate the effect of baking time- temperature and humidity on biscuits quality. The study also investigated the quality of flour used for biscuit manufacture and studied the ultimate quality and shelf life of some brands of biscuits in Nabisco Biscuit & Bread Factory Ltd, Dhaka, Bangladesh. The study showed that the baking temperature and time were 240 °C for 5.5 minutes, and 250 °C for 3-4 minutes respectively for 5 mm diameter biscuit in average. The biscuits baked at lower temperature and longer time had the lowest moisture. Higher temperature takes less baking time on the other hand lower temperature takes longer baking time. The increase or decrease of time- temperature combination is adjusted with speed of the conveyor belt. The study also explained the mode of heat transfer in the oven during baking process. Keywords: baking, flour, biscuit quality, time- temperature, heat transfer, dough formation, moisture, speed of conveyor belt etc. Introduction Biscuits, which are chemically leavened baked products, are one of the most delicious foods liked by most people. They are stable foods and have advantages such as long shelf life and good eating quality. The physical properties of the dough and the recipes in biscuit making depend on the types of biscuit and the method used in the dough formation. Quality standards from the raw materials 1 Associate Professor, Department of Food Engineering & Technology, State University of Bangladesh 2 Lecturer, Department of Food Engineering & Technology, State University of Bangladesh 1 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 to the end product are essential in biscuit making to ensure food safety. The delicious smell of biscuit is produced as a result of the interaction of various chemical and physical processes that can be adjusted to create a great variety of products. Baking is obviously one of the most important stages of biscuits production. Biscuit quality and baking time also change with oven design and operating parameters. These parameters must be well established and controlled for each type of baked products. In the production of biscuit dough, dough-mixing procedure, packaging of the product, storage period should be well established for high quality product. Baking time and oven temperature have greatest effects on biscuits quality. The aim of this study was to investigate the effects of baking time and temperature on biscuits quality and its shelf life to investigate the effects of baking temperature, time and humidity on biscuits qualities and subsequently find the relationship between biscuit crust and crumb properties. This study has evaluated the effects of different temperature and time combination on the quality of biscuits. Baking is a very important process but is very complex and somewhat difficult to understand and describe. The design and control of an oven is principally a matter of heat transfer, but for the baker it is a matter of temperatures and turbulence at specific stages. Heat and temperature are not the same and should not be confused. It is relatively easy to measure temperatures in an oven but much more difficult to measure heat, or heat flux, which is the rate at which heat is being transferred. Heat is transferred much more effectively if the air is moving near the dough piece at a given temperature. Nearly all biscuits are now baked in band or travelling ovens with several independently controlled zones. This means that oven conditions such as temperature, movement and humidity of the atmosphere may be altered during the course of the baking period. 2 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 Baking times for biscuits are quite short, ranging from 3-5 minutes. It is not normally possible to change quickly, the temperature of a static or reel oven so the results of baking in these ovens compared with that in travelling ovens are often very different. The conditions needed for different types of biscuit are not the same because the way in which the structure is developed and the amount of moisture that must be removed depends on the richness level of fat and sugar of the recipe. Materials and Methods Materials: The principal raw materials for biscuit manufacture were flour, milk powder, sugar, sodium bicarbonate, mould, potable water, flavor, etc. Equipments: Direct Gas Fired (DGF) oven was used with visibility of the burners. Control options extend from a PLC with a touch screen operator interface to a full SCADA system. Variable speed fans instead of dampers provide a linear response for improved process control. PMB moisture analyzer, with heating element: Single 400 wart halogen heater and operating temperature was 30-104ᵒF \ 0-40ᵒC was used for analysis of moisture. Refractometer and digital pH meter were used for determination of brix and pH respectively. Place of Experiment: This experiment was conducted by the department of Food Engineering & Technology, State University of Bangladesh, at the Quality Control Laboratory, Nabisco Biscuit and Bread Factory Ltd. Dhaka, Bangladesh. Analysis of Flour: In this study commercially available flour of different brands such as Dawan from Dawan Flour Mills, Narayngong; Green Bird from Mofiz Flour Mills, Tangail; Islamia from Islamia Flour Mills; Sonali from Sonali Flour Mills, Tangail and ACI pure from ACI pure Flour Mills, Narayngong were used as principle raw material depending on the types of biscuit. At first the moisture content of flour was tested. Five (5) gm of each flour 3 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 sample was tested for moisture content using PMB moisture analyzer, which had heating element: Single 400 wart halogen heater and operating temperature was 30-104ᵒF \ 0-40ᵒC. Gluten content of flour was tested by analytical method. 50 gm flour was taken to prepare dough using 25 ml 2 % NaCl solution and mixed into dough with a spatula. Then was kneaded the dough gently under water for 10-15 minutes, so that soluble matter and starch were washed away. KI was used to control presence of starch. Then rolled dough into a ball was weighed the moist gluten and expressed as percentage of flour. Then it was dried at 100oC to constant weigh and expressed repeat as a percentage of flour. Test of milk powder: Fresh milk powder (Manufacturing date: 20-07-2011 and Expire date: 20-01-2012) was tested for solubility properties, color and flavor. Brix analysis of sugar: 50% sugar solution was prepared and tested by refractometer. The brix chart (adjusted with temperature of that day using thermometer) was used to obtain brix of sugar solution. pH test of potable water: Digital pH Meter was used to test pH of water. Preparation of biscuits: Formulation of biscuits is shown in Figure-1. The volatile flavor of interest was added at the creaming stage, using propylene glycol (1 ml) as the carrier solvent, ultimate concentration 250 ppm by weight. Volatile loss during the mixing step was not quantized, but would not have been considerable at room temperature. However, mixing was minimized to avoid this loss, without compromising thorough distribution of the volatiles. Extraction and analysis of volatiles from individual finished biscuits showed a low level of biscuit-to-biscuit variation, suggesting that the mixing stage was efficient (Michael S. Brauss et al., 1999). In order to examine the effect of baking time on volatile release in-nose, dough samples from the same batch were baked in the cookie oven for various times. 4 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 Figure 1: Flowchart illustrating production process for biscuit manufacture Moisture test of biscuits: PMB moisture analyzer, having heating element: Single 400 wart halogen heater and operating temperature was 30-104ᵒF \ 0-40ᵒC was used to test moisture content of Sugar free biscuit, Carlton biscuit and Glucose MPP biscuits after production. Five (5) gm of powdered biscuit was used to perform this operation. Organoleptic tests of biscuits: The organoleptic properties of Butter Cookie, Glucose MPP, All Time, Sugar free biscuit and Carlton biscuits were tested. Color, flavor, texture, bite, acoustics (cracking of biscuits), baking color, foreign material, objectionable material, metallic contamination, sour taste and burnt properties were frequently tested. 5 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 Shelf life study of biscuits: Biscuit weight and moisture were measured weekly to test shelf life. Results and Discussion Effect of time-temperature combination: The oven has 6 zones for controlling temperature. The different zones with gradual increase or decrease of temperature are named as: a) Heating zone (zone-1 & 2) b) Baking zone (zone- 3, 4 & 5) c) Coloring zone (zone-6) The average temperature of zone-1 and zone-2 was relatively warmer- 95.65°C and 177.39°C respectively (Table-1). The warmer the temperature, the more active our yeast will be. The more active our yeast is, the quicker the dough rises. In these zones relatively all moisture of dough are removed. The loss of moisture from biscuit is related to the temperature, heat flux and water vapor at the surface. Moisture is lost from the dough surface because of migration of water to the surface by capillary action and diffusion. Both of these phenomena are accelerated by temperature gradients. The centre of dough piece is heated principally by conduction of heat, but as the crust dries it act as an insulator and make it more difficult to heat the centre. (Chevallier et al., 2002). During this period color change occur prematurely. The average temperature of zone-3 is 214.34°C. In this zone gas bubbles and water vapor are formed which expand and result in a large reduction in the density of the dough. The possible reason of this mechanism includes heating of starch and gluten resulting in gelatinization of starch and denaturation of gluten; which cause swelling (Chevallier et al., 2000). Bubbles of gas are liberated due to increasing temperature which also increases the water vapor (Broyart et al., 2002). The average temperature for zone-4 and zone-5 was 302.60°C and 324.34°C respectively. During this period, the characteristic color and flavor of biscuit is developed. The color becomes yellowish brown, which merely darkens 6 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 (Mundt et al, 2007). Reduction in reflectance of the biscuit surface also occurs (Shogren et al., 1998). The possible mechanism is occurrence of maillard reaction and non-enzymatic browning, which involves the chemical reaction between reducing sugars in the dough with proteins and produces the attractive color (Brauss et al, 1999). Color also develops from caramellization of sugar. In order to prevent parts of the edges of the dough pieces becoming over colored it is important to arrange that they are placed close together on the oven band with adjusted spaces between them. If edges are over heated or burnt, then biscuit is not packaged or rejected. The average temperature of zone-6 is 169.56°C. During this period desired texture of biscuits is obtained (Ahmad et al., 2001). Table 1: Temperature Monitoring by Oven Thermometer Oven zones Parameters Levels Zone1 Zone2 Zone3 Zone4 Zone5 Zone6 Temperature (ᵒC) Mean 95.65 177.39 214.34 302.60 324.34 169.56 Table 2: Time-Temperature combination Baking time Zone 1 Zone 2 Zone 3 Zone 4 3.0 – 4.0 min. 210°C 290°C 320°C 180°C 5.5 min. 180°C 270°C 310°C 200°C Oven temperature is always controlled. Speed of the conveyor belt is adjusted according to temperature of the oven. At the above adjusted temperatures of different zones of the oven, 5 mm diameter thick biscuit takes about 5.5 minutes to be completed. Table-2 shows that if baking time is lowered to 3-4 minutes from 5.5 minutes, subsequently baking temperature is increased. Temperature of zone 1 increased from 180°C to 210°C. Same phenomenon occurs in case of other zones (Table-2). If the speed of conveyor belt is made slower or faster, then temperature of the 7 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 oven must be adjusted depending on the speed. Otherwise biscuit will not be produced properly. Thus baking is a matter of finding the best conditions of heat and time to allow structure development, surface coloration and drying of centre. Thicker biscuits need longer bake times at lower temperatures to achieve this drying. Thin and small biscuits can be baked faster at higher temperatures. Heat transfer process during baking: Direct Gas Fired (DGF) oven was used with visibility of the burners. The heat is provided by burning gas and transferred by the three modes known as radiation, conduction and convection. Three modes are always involved though engineering techniques are used to enhance the effects of each separately. Dough pieces are supported on a baking surface which is usually a sheet of steel. On entering the oven, heat is applied to the dough piece by a combination of conduction (through the baking surface), convection (from the hot air moving in the oven) and radiation (from hot surfaces of the structure of the oven). Radiant heat, at the wave lengths involved, does not penetrate the dough piece significantly. The most effective form of heat transfer is by convection but moving hot air also sweeps away moisture and dries the dough surface very rapidly. Moisture removal process: As the moisture evaporates from the product a rise in pressure in the oven occurs. In the case of direct fired ovens where gas is burnt in the baking chambers, the increase in pressure is even greater. This pressure must be relieved so flues are provided which exhaust to the atmosphere. Later, as the dough temperature rises, water will again evaporate and retard the rate at which the surface temperature rises. The wetting of the dough surface at the oven entrance aids the general rise in temperature of the dough piece and maintains the flexibility of the "crust" longer. It would be ideal if the dough piece could be heated uniformly and rapidly before much moisture is lost. During this drying phase and before the surface becomes too dry the temperature may be adjusted to give a desired level of coloration to the biscuit. 8 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 Quality of the raw materials: Moisture is an important parameter in flour that significantly affects shelf life and growth of microbial contaminants (ICMSF 1998). In the BDS 382 as well as in the Codex Alimentarius Standard (1995), the maximum moisture in flour is defined as 13% and 15.5%, respectively (Siddique & Chowdhury, 2013). In this study the moisture in Bangladeshi wheat flour samples used in biscuit manufacture were tested, which ranged from 12.15 ± 0.26% to 13.63 ± 0.59%. Gluten content of different flour brands ranges from about 22-26 g in 100gm. Wheat flour of these gluten ranges are appropriate for biscuit manufacture. Only ACI brand had 38 g of gluten. That’s why this flour is used for bread making instead of biscuit. Milk powder had proper solubility property and desirable color and flavor. Brix of sugar was satisfactory and pH of water used in the operation was 7.2. Table 3: Chemical quality parameters of wheat flour samples Parameters and legal limits Levels Moisture (%) Max 13%2 Max15.5%3 Gluten (within 100 g) Brand Name 1 G S D A I Mean ± SD 12.52 ± 0.70 13.12 ± 0.42 12.92 ± 0.37 12.77 ± 0.49 12.63 ± 0.76 Mean ± SD 24.30 ± 0.05 22.37 ± 0.07 27.8 38.87 ± 0.049 28.28 ± 0.062 ± 0.09 1: Brand name: G-Green Bird, S-Sonali, D-Dawan, A-ACI Pure, I-Islamia. 2: Maximum acceptable limits of wheat flour according to BDS 382:2001 3: Maximum acceptable limits of wheat flour according to Codex Alimentarius Standard (1995). 9 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 Table-4: Quality test of different brands of biscuits Name of Biscuit Butter Cookies Glucose MPP All Time Sugar free biscuit Carlton biscuit Interval between Mfg. & testing (day) 0 14 16 45 0 Moisture (Max-5) 1.77 1.79 2.08 2.13 1.39 14 1.39 16 45 0 14 16 45 0 14 16 45 0 14 16 45 1.45 1.5 1.53 1.5 1.75 1.79 1.94 2.16 1.11 1.76 1.54 2.49 2.19 1.06 Taste Flavor Color Sweet Pleasant Specific Sweet Pleasant Specific Sweet Pleasant Specific Salty Pleasant Specific Sweet Pleasant Specific After monitoring oven temperature during manufacture, quality of different brands of biscuits were tested. Moisture content, taste, flavor and color of biscuits were monitored. The intervals of testing were- the day of manufacture (0 day), 14th day, 16th day and 45th day after manufacture. Butter cookies, Glucose MPP, All time, Sugar free biscuit and Carleton biscuits were selected for these tests. According to BDS 382 as well as in the Codex Alimentarius Standard (1995), the maximum level of accepted moisture in biscuits is 5. The BSTI standard of % moisture for biscuits is also 5 (Islam & Haque, 2013). All biscuits, except sugar free biscuits had sweet taste. Sugar free biscuit had salty taste. Flavor and color of all biscuits were pleasant and specific respectively. 10 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 Conclusion The general rule is that crusty biscuits should be baked at as high a temperature as possible. Soft dough biscuits should be baked at lower temperatures. Increasing baking temperature with adjustment of conveyor belt speed may reduce baking time effectively. In the study, qualities of the raw materials were tested and the manufacturing process and quality of different kinds of biscuits were also studied. All flour had satisfactory moisture and gluten level, except ACI pure had exceeded level of gluten, hence not suitable for biscuit manufacture. Moisture content, taste, flavor and color of all biscuit brands were found satisfactory. Acknowledgements Authors gratefully acknowledge the Nabisco Biscuit & Bread Factory Ltd. For allowing to perform this work using analytical laboratory facilities of the factory. References Ahmad, S.S., et al. 2001. Effects of microwave on the drying, checking and mechanical strength of baked biscuits. Journal of Food Engineering. 50: 63-75. Berghofer, L.K., Hocking, A.D., Miskelly, D. and Jansson, E. 2003. Microbiology of wheat and flour milling in Australia. Int J Food Microbiol. 85: 137-149. Brauss, M.S., et al. 1999. Fat content, bak ing time, hydration and temperature affect flavour release from biscuits in model-mouth and real systems. Flavour and Fragrance Journal. 14: 351–357. Broyart, B., et al. 2002. Modelling heat and mass transfer during the continuous baking of biscuits. Journal of Food Engineering. 51: 47-57. Chevallier, S., et al. 2000. Contribution of Major Ingredients during Baking of Biscuit Dough Systems. Journal of Cereal Science. 31: 241252. Chevallier, S., et al. 2002. Structural and Chemical Modifications of Short Dough during Baking. Journal of Cereal Science. 35: 1-10. 11 Siddique, AA & Nasreen, L Journal of SUB 5(1): 1-12, 2014 Codex Alimentarius Standard (1995) Codex Standard for wheat flour. (www.codexalimentarius. net/download/standards/50/CXS_152 e.pdf Codex Stan 152-1985) Rev.1-1995. Dogan, I.S. 1998. Factors affecting cookie quality. Food Technol. 3: 7276. Eyles, M.J., Moss, R. and Hocking, A.D. 1989. The microbiological status of Australian flour and the effects of milling procedures on the microflora of wheat and flour. Food Australia. 41: 704-708. Islam, G.M.R. and Hoque, M.M. 2013. Food safety regulation in Bangladesh, chemical hazard and some perception to overcome the dilemma. International Food Research Journal. 20: 47-58. ISO 712 (1985) Cereals and milled cereals products- determination of moisture content (Routine reference method), International Standardization Organization, Switzerland. Mundt, S., et al. 2007. A kinetic model for browning in the baking of biscuits: Effects of water activity and temperature. LWT - Food Science and Technology. 40: 1078-1082. Ottogalli, G. and Galli, A. 1979. Microbiological quality of flours: sour dough for bakery products and spaghetti. In: Proceedings of the International Meeting on Food Microbiology and Technology. (Jarvis, B., Christian, J.H.B. Michener,H., Eds.), Tabiabo (Parma). pp. 141-153. Principles of baking (http://www.thebiscuitdoctor.com/manufacturingprocesses/81-resources/ processes-baking/180-principles-of-baking.) Retrieve on 11/12/13. Shogren, R.L., et al. 1998. Starch–poly (vinyl alcohol) foamed articles prepared by a baking process. Journal of Applied Polymer Science. 68: 2129–2140. Siddiqui, A.A. and Chowdhury, N.A. 2013. Physico-Chemical & Microbiological Quality Assessment of Different Popular Brands of Wheat Flour, Available in Bangladesh . Journal of SUB. 4:57-65. 12