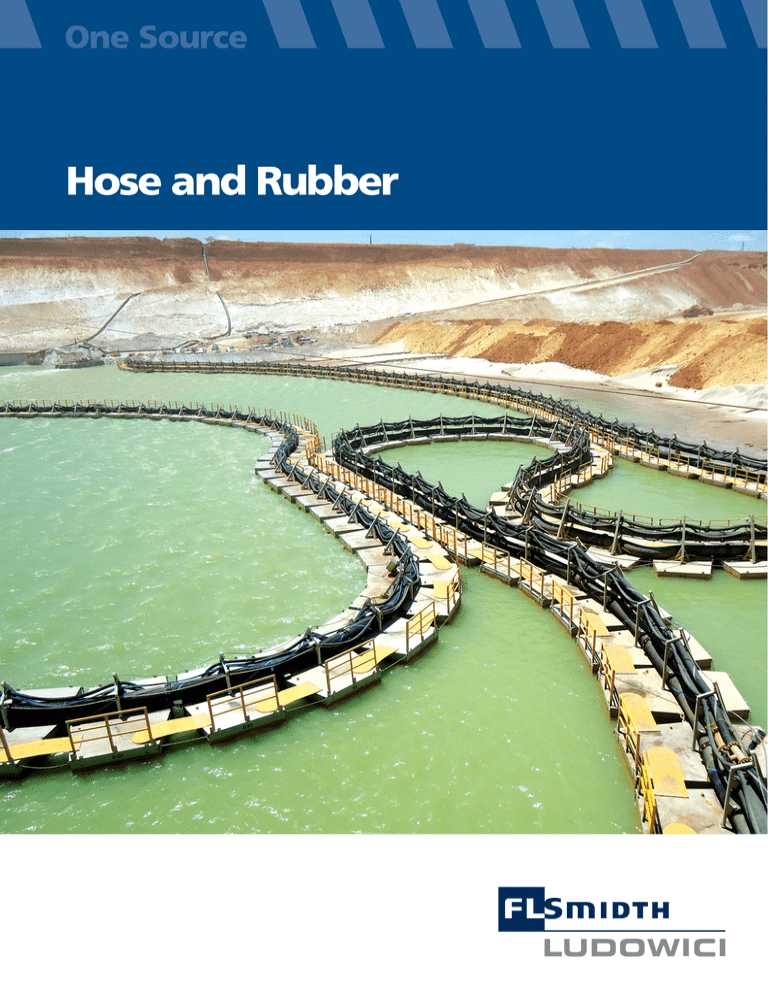

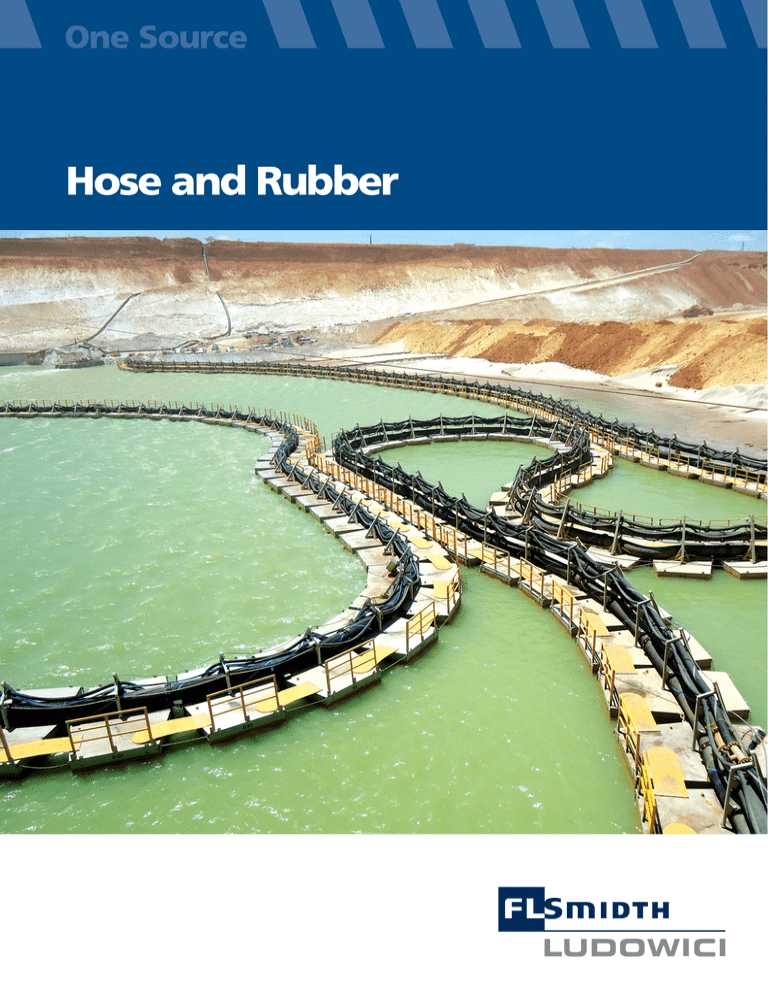

Hose and Rubber

2

Material Handling Hoses

The FLSmidth® Ludowici® LUDOFLEXTM range

of high quality, material handling hoses are

suitable for use in a range of abrasive slurry

applications, from hard rock mining and

mineral sands, to waste and refuse handling.

FLSmidth Ludowici has the hose to suit your

needs.

2

3

1

1. Tube Liner

2. Reinforcement

3. Outer (top) cover

Specifications

Ideal For

•

•

•

•

•

•

Slurry handling including

quarry products, ore, tailings,

coal slurries and fly ash

Waste and refuse handling

Pollution control

Materials transfer

Hydraulic dredging

Sandblasting

Benefits:

• High abrasion resistance - suitable for the

most abrasive slurries

• Tough and durable construction utilising a

hot-vulcanised manufacturing process

• Versatile applications supplied with choice

of fixed (integral) flanges, beaded

(rotating) flanges, reinforced spigot

flanges or muff couplings

• Reliable performance with flexible hose

construction minimising misalignment

• Advanced vibration absorption technology

to reduce wear and tear

• Exceptional noise minimisation

• Products backed by optional personalised

hose auditing service

•

•

•

•

Size - inside diameter 25NB

to 1200NB

Length - custom-built up

to 12metres

Working pressure - up

to 4800kpa (685PSI)

Safety factor - 4:1

Features

•

•

•

•

•

Tube liner comprises special wearresistant, natural and synthetic

compounds or a selection of chemical

and heat-resistant polymers

(*1 – figure 1)

Reinforced in fabric plies of polyester

cord with machine wound, high tensile,

spring wire helix (*2 – figure 1)

Outer cover manufactured from high

quality, UV-stabilised or chemical

resistant compounds (*3 – figure 1)

UV-stabilised top cover to withstand

harsh elements

Unique wear indicator performance

system for better hose maintenance

3

End Connections

Fixed (Integral) Rubber Flanges

Fixed Flanges provide quick, economical and hard-wearing connections

in medium to high pressure applications. The reinforcing plies and tube

liner are melded to the outer diameter of the steel flange to securely

seal connections between the hose and other fittings. The flange can

also be enclosed with reinforcing ply and rubber as a safeguard in

corrosive applications.

Beaded (Rotating) Flanges

Beaded Flanges allow the flange or hose to be rotated in situ.

This allows ease of bolt hole alignment and better management of

abrasive wear to optimize hose life.

Spigot Flanges

Reinforced Spigot Flanges are especially suited for high pressure,

heavy duty applications in mining and dredging. They consist of an in

built tail over in which the tube liner, reinforcing and outer cover are

vulcanized so that the hose is able to withstand substantial end pull

and movement.

Double Flanges

The Double Flange comprises twin steel flanges at each end of the hose

and incorporates rubber mouldings to ensure a secure seal from hose

to fittings. Stronger than a standard fixed flange, the double flange is

the ideal solution for hoses subject to significant movement.

4

Muff Coupling Hose

The FLSmidth® Ludowici® LUDOFLEXTM

muff coupling hose is purpose designed

to handle pressure or suction in the

transfer of the most abrasive material

including bulk, slurry and cement.

Benefits

• Exceptional abrasion resistance

• Flexible configuration

accommodating split muff

coupling flanges

• Quick installation with ordinary

hand tools and no specialist

machinery required

• Easy field repair to reduce downtime

• Customised hose length cut on-site

to fit a variety of couplings and suit

any application

Inside Diameter (NB)

Ideal For

•

•

•

Slurry lines

Cyclone feed circuits

HDPE pipe connection

Outside

Diameter

Working

Pressure

Weight

mm

Inches

mm

(kPa)

(kg/m)

75

3

102

700

5

100

4

128

700

7

125

5

156

700

8

150

6

182

700

10

200

8

235

700

16

250

10

287

700

21

300

12

345

700

31

350

14

390

700

41

400

16

458

700

60

Features

•

•

•

•

•

Temperature range –20 degrees C to +125 degrees C

Purpose built for use with split muff couplings

Abrasion resistant natural rubber tube and high tensile synthetic lining

Reinforced in high tensile synthetic cord and steel wire helix

UV-stabilised and ozone resistant

5

Dredge Hose

FLSmidth Ludowici manufacture and

supply a wide range of material handling

hoses specifically designed to deliver

optimal suction or discharge in heavy

duty dredging.

Benefits:

• Heavy duty, robust construction able

to handle the harshest materials

including the corroding effects of

marine applications and

abrasive slurries

• High abrasion resistance with soft or

hard wall assembly

• Flexible applications with range of

fittings including fixed (integral),

beaded (rotating), spigot and muff

coupling flanges or soft cuff,

swollen cuff or plain cut finishes

• Tailor-made to specific applications

including customised wear liner and

buoyancy

Ideal For

•

•

•

•

•

•

Rock and sand suction

Minerals separation

Offshore rock cutter

discharge

Slurry handling

Hopper bow connection

discharge

Land reclamation

Feed size

•

•

•

Size - 150NB to 1200NB

Length - up to 12 metres

Working pressure up to

4800Kpa (685PSI)

Features and Benefits

•

•

•

•

Fabricated from a range of the finest

grades of natural and synthetic rubber

compounds, cord materials and fabric

Annular ring or spring wire helix

construction to ensure flexibility and

withstand full vacuum pressure during

service

Polyester reinforcement to provide

strength and accommodate movement

in the line

Customised to self-floating

specifications or supplied with

polyurethane floats

6

Preformed Hose Bend

The FLSmidth® Ludowici® LUDOFLEXTM

Preformed Rubber Hose Bends comprise

high quality precision-moulded units in a

range of diameters, bend angles and

radius configurations to suit different

suction and delivery needs.

Benefits:

• High abrasion resistance suitable

for the most abrasive slurries

• Tough and durable construction

utilising a hot-vulcanised

manufacturing process

• Versatile applications supplied

with fixed (integral) flanges or

beaded (rotating) flange

• Supplied with soft cuff, swollen

cuff or plain cut ends to suit

different uses

• Cut to suit specific customer

requirements

• Bend radius suited to variety of

work areas including the tightest

plant layouts

• Reduces noise and vibration

Ideal For

•

•

•

•

Slurry handling including

quarry products, ore, tailings,

coal slurries and fly ash

Waste and refuse handling

Pollution control

Materials transfer

Feed size

•

•

•

Size - inside diameter 25NB to

1200NB

Working pressure - up to

4800kpa (685PSI)

Safety factor - 4:1

Features and Benefits

•

•

•

Hose Bend Liner comprises special

wear-resistant, natural and synthetic

compounds or a selection of chemical

and heat-resistant polymers

Reinforced in fabric plies of polyester

cord with machine wound, high

tensile, spring wire helix

Outer cover manufactured from high

quality, UV-stabilised or chemical

resistant compounds

7

Customised Expansion Joints

FLSmidth Ludowici offers customised

expansion joints to assist in optimising

vibration dampening and isolation and

to accommodate the misalignment of

pipeline connections.

Benefits:

• Rugged, hardwearing fabrication

in a wide range of elastomers

• High corrosion resistance in a wide

range of temperatures

• Low maintenance with reduced

turbulence, sediment build-up

effects and area of thrust

• Reduction of stress due to

extension and contraction

• High insulation against noise

and vibration

• Extended pipe wear with excellent

compensation for misalignment

• Reduced maintenance costs

• Customised to suit individual

needs and specifications

Feed size

Ideal For

•

•

•

•

•

•

•

•

Air conditioning

Industrial applications

Ventilation

Petrochemical handling

Piping systems

Marine services

Water and sewerage systems

Applicable fluids include

water, air, warm water,

seawater, weak acids and

alkalies

•

•

•

•

Size from inside diameter

- 50NB to 2700NB

Temperature range –20

degrees C to +125 degrees C

Working pressure - up to

4800kpa (685PSI)

Safety factor - 4:1

Features and Benefits

•

•

•

•

Standard single arch-moulded

joint construction

Neoprene inner lining cover

and coating

High tensile synthetic ply

reinforcement

Length tailored to

accommodate a range of

movement differentials

8

Custom designed

Single Unfilled Arch Type

Eccentric Reducers

Concentric Reducers

For equipment with different size flanges

To connect pipe of unequal diameters

Sleeves for Flangless Pipe

Multiple Arches For Movement

Hose Type

Economical and used with low

Double-triple-quadruple flexibility

Ideal for vibrations - pump connectors etc

pressure installations

Filled Arches for Slurries

Enlarged Flanges

Reduce turbulence with smooth bore

For unusual drilling patterns

NOTE: Control Rods depicted above are optional - depending on the specific application

9

Expansion Joints for piping application

Quality materials and workmanship

give extended service life to

FLSmidth Ludowici LUDOFLEX

products.

Hypalon Cover Coating - provides

extra protection against ozone,

weather and the environment.

Elastomer Cover - made from

natural, neoprene, nitrile, butyl,

hypalon and EPDM to resist the

atmosphere’s effects to the product.

Deep and Wide Arch - provides

controlled resilience at the hinge

point with maximum movement.

fabric. Product design pressure (positive/

negative) may determine the use of other

fabrics depending on the relationship of

fabric plies to the body reinforcing rings.

Reinforcing Rings – made of

heavy-duty solid steel and

embedded in elastomer for

maximum pressure and

vacuum service.

Extra Flange Plies – are built-in for

greater strength and integrity between

body and flanges.

Elastomer Filler - used between

reinforcing rings to absorb vibration,

sound and electrolysis.

Backing Flanges – made from mild

steel, galvanized or stainless steel

on request.

Body Fabric - high tensile

elastomer impregnated synthetic

Control Unit Assemblies - prevents

over-extension of expansion joints.

Item #

Materials

Part

1

Inner Liner & Cover

Coating

Neoprene

2

Reinforcement

High Tensile Synthetic Plys

Flanges

Galvanised Carbon Steel BS

Table ‘E’ is standard. Also

ANSI, BS, Drilling avaliable

3

Allowable Movement (mm)

Operating Condition

Diam.

DØ

mm

L (mm)

Axial

Compression

Axial

Elongation

Transverse

Deflection

Angular

Deflection

Max. Pressure

KPA (PSIG)

Max. Temp

C ° (F °)

Vacuum

Rating

mm Hg

32

40

50

65

80

100

125

150

200

250

300

350

400

95

95

105

115

130

135

170

180

205

240

260

265

265

8

8

8

12

12

18

18

18

25

25

25

25

25

4

4

5

6

6

10

10

10

14

14

14

16

16

8

8

8

10

10

12

12

12

22

22

22

22

22

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

1030 (150)

1030 (150)

1030 (150)

1030 (150)

1030 (150)

1030 (150)

1030 (150)

1030 (150)

1030 (150)

1030 (150)

1030 (150)

700 (100)

700 (100)

90 (194)

90 (194)

90 (194)

90 (194)

90 (194)

90 (194)

90 (194)

90 (194)

90 (194)

90 (194)

90 (194)

90 (194)

90 (194)

400

400

400

400

400

400

400

400

400

400

400

400

400

10

Rubber Lining

FLSmidth Ludowici manufacture and

supply premium rubber linings offering

superior corrosion protection in pipes,

vessels, valves, chutes and other

fabricated items.

Benefits:

• Hardwearing and durable

components manufactured from

premium rubber compounds,

elastomers and polymers

• Flexible applications suitable for

mechanical, thermal and chemical

processes

• Customised for extremely high

abrasion resistance for aggressive

media with high solids content

• Wide application on a variety of

substrates including steel,

aluminium, fibreglass, concrete and

exotic metals

• Cost effective and economical,

extending equipment life and

maximising operational efficiencies

Ideal For

•

•

•

•

•

Corrosion protection

Vibration dampening

Electroplating

Environmental protection

Wet protection

Features and Benefits

•

•

•

•

•

Australian designed and manufactured to suit local and export conditions

Linings compounded from natural and synthetic elastomers

Available in autoclave vulcanised and cold cure bonded systems

Complies with BS6374: Part 5:1985 and external coatings, when required

Expert installation on site or at the FLSmidth Ludowici factory

11

Jetslinger Belts

The FLSmidth® Ludowici® Jetslinger Belts

are an integral component to our range

of Jetslingers, a fast, flexible and highly

productive means of stockpiling free

flowing bulk materials, such as coal and

ores, in places that may be inaccessible

by other mechanical means.

Benefits:

• The FLSmidth Ludowici range of

high quality Jetslinger Belts are

hand-built and constructed endless

on drums

• These belts are custom made with a

wide range of sizes available

• Jetslinger Belts are manufactured

using a hot-vulcanised procedure to

achieve maximum strength and

performance

Ideal For

•

•

•

•

Stockpiling

Ship loading

Bulk material handling

Mineral separation

Features and Benefits

•

•

•

•

Manufactured from premium rubber compounds including Natural

Rubber, FRAS Rubber and Nitrile Rubber

Diameter and width to suit customer’s requirements

Australian designed and manufactured to suit local and export conditions

Full Quality Assurance and Quality Control System in line with world’s

best practices

representations or warranties (express or implied), and information and data contained in this brochure are for general reference only and may change at any time.

www.flsmidth.com

Rev.21/08/2013 pjoh-au

Copyright © 2013 FLSmidth A/S. ALL RIGHTS RESERVED. FLSmidth and LUDOFLEX are (registered) trademarks of FLSmidth A/S. This brochure makes no offers,