Swivel drives

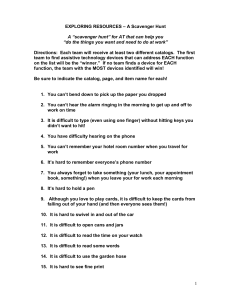

Semi-rotary vane drives

Swivel modules DSM

4.1

Compact swivel actuators with

minimum space requirement

Adjustable swivel angle

Specified types in accordance with

ATEX directive for potentially

explosive atmospheres

www.festo.com/en/ex

2006/03 – Subject to change – Products 2006

1 / 4.1-1

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Key features

At a glance

The technology in detail

1

2

3

5

6

7

4

8

1 Smooth operation thanks to

machined surfaces

2 Polyurethane assures long

service life for rotary vane and

sealing system

DSM-6 … 10

Swivel modules DSM-6 through 10 are

vane driven double-acting semi-rotary

actuators. The swivel angle is

infinitely adjustable. End-position

cushioning is accomplished with

flexible cushioning plates on the

rotary vane.

The swivel modules are splash-water

and dust proof.

Wide choice of variants

DSM with spigot shaft

DSM with fixed stop

2

3 Torques of up to 20 Nm with

rotary vane in combination with

spline shaft

4 Versatile, integrated mounting

facilities

5 Swivel angle can be set anywhere

within the swivel range

6 Mounting facility for inductive

proximity sensors using sensor

bracket, for contactless position

sensing

7 Manual operation via internal

hexagon socket in the drive shaft.

A female thread is included for

attachment of an additional drive

shaft by the user

8 Fixed stop with fine adjustment

of the swivel angle

DSM-12 … 40

Swivel modules DSM-12 through to

40 are vane driven double-acting

actuators with infinitely adjustable

swivel angle over the entire range.

End positions can be adjusted by

means of stop screws and lock nuts.

Impact energy from the stop lever is

absorbed by flexible cushioning

plates on the basic versions.

End position cushioning is accomplished by means of YSR shock

absorbers with CL/CR/CC variants. The

rotary vane itself is not suitable for

use in defining end positions, i.e. the

stop lever and the stops may not be

removed.

The swivel modules are splash-water

and dust proof.

DSM with spigot shaft and freewheel

unit FLSM (accessories)

DSM with flanged shaft FW

DSM-12 … 40 with shock absorber

on left CL

DSM-12 … 40 with shock absorber

on right CR

Internet: www.festo.com/catalogue/...

DSM-12 … 40 with shock absorber

on both sides CC

Subject to change – 2008/06

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Key features

Mounting options

DSM-6 … 10

DSM-12 … 40

Base thread

Threaded through-hole

Threaded through-hole

Position sensing

DSM-6 … 10

Centring collar

DSM-12 … 40

Proximity sensor SME-10/SMT-10

Mounting kit for proximity

sensor

Mounting facility on

adjustable stop or shock

absorber retainer

Marking for magnet position

Mounting kit for proximity sensor

Magnet holder

-H-

Inductive proximity sensor

SIEN

Recommended:

Note

If a swivel module with position

sensing is to be attached to a ferritic

component, the diagram opposite

should be observed in order to

assure reliable switching of the

proximity sensor.

2008/06 – Subject to change

Not recommended:

Internet: www.festo.com/catalogue/...

3

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Product range overview

Function

Version

Type

Doubleactingg

with fixed swivel angle

DSM-6 … 10

with adjustable swivel angle

DSM-6 … 10

DSM-12 … 40

4

Size

Max. swivel angle

[mm]

[°]

6, 8

90, 180

10

90, 180, 240

6, 8

180

10

200

12,, 16,, 25,

5, 332,, 40

270

Internet: www.festo.com/catalogue/...

Position sensing

Spigot shaft

Flanged shaft

FW

Subject to change – 2008/06

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Product range overview

Type

Fixed stop

Shock absorber

Left

CL

Page/Internet

Right

CR

At both ends

CC

with fixed swivel angle

DSM-6 … 10

8

–

–

–

with adjustable swivel angle

DSM-6 … 10

8

–

–

–

DSM-12 … 40

20

2008/06 – Subject to change

Internet: www.festo.com/catalogue/...

5

Swivel modules DSM

Peripherals overview DSM-6 … 10

6

7

1

2

3

5

4

Accessories

1

End stop kit

KSM

2

Mounting kit

WSM-…-SME-10

3

Proximity sensor

SME/SMT-10

Push-on flange

FWSR

Freewheel unit

FLSM

One-way flow control valve

GRLA

Push-in fitting

QS

4

5

6

7

6

Brief description

Page/Internet

For swivel angle adjustment;

expandable for swivel module DSM-…-P(-A)/DSM-…-P(-A)-FW

an adapter and socket head screws must also be ordered for installation of the stop kit

33

For sensing the swivel angle;

for mounting proximity sensors SME-/SMT-10;

expandable for swivel module DSM-…-P(-FF)/DSM-…-P(-FF)-FW

an adapter and socket head screws must also be ordered for installation of the mounting kit

33

33

Proximity sensor for end position sensing

33

Accessory for swivel module DSM with spigot shaft

32

Only in conjunction with swivel module DSM with spigot shaft

28

To regulate speed

34

For connecting compressed air tubing with standard external diameters

quick star

Internet: www.festo.com/catalogue/...

33

Subject to change – 2008/04

Swivel modules DSM

Type codes DSM-6 … 10

u

DSM

—

8

—

180

—

P

—

A

—

FF

—

FW

Type

Double-acting

DSM

Swivel module

Size [mm]

Swivel drives

Semi-rotary vane drives

Max. swivel angle [°]

Cushioning

P

Non-adjustable at either end

Position sensing

A

No position sensing

For proximity sensing

4.1

Adjustable swivel angle

FF

Fixed swivel angle

Adjustable swivel angle

Shaft

FW

Spigot shaft

Flanged shaft

2007/03 – Subject to change – Products 2007

1 / 4.1-7

Swivel modules DSM

Technical data DSM-6 … 10

Function

-N-

Size

6 … 10 mm

General technical data

Size

Pneumatic connection

Design

Cushioning

Type of mounting

Assembly position

Max. swivel angle

g

Permissible frequency at 6 bar

Max. cushioning angle

Air consumption

p

at max. swivel angle

g

and 6 bar1)

1)

6

Fixed

Adjustable

90°

180°

240°

[°]

[°]

[Hz]

[°]

[cm3]

[cm3]

[cm3]

Operating medium

Operating pressure

Temperature range1)

CE symbol

6

[bar]

[°C]

Torque at 6 bar

Max. perm. radial load on drive shaft

Max. perm. axial load on drive shaft

Max. perm. mass moment of inertia on the drive shaft1)

8

90, 180 or 240

0 … 200

3 (with 240°: 2 Hz)

5.5

11

15

8

Filtered compressed air, lubricated or unlubricated

3.5 … 8

3.5 … 8

0 … +60

Atex

10

2.5 … 8

Note operating range of proximity sensors

Forces and torques

Size

1)

10

Theoretical values

Operating and environmental conditions

Size

1)

8

M3

Rotary vane

Flexible cushioning rings/plates at both ends

Via female thread

Any

90 or 180

90 or 180

0 … 180

3

0.5

0.6

0.7

1.2

1.4

–

[Nm]

[N]

[N]

[kgm2]

6

8

10

0.15

15

10

0.05 x 10–4

0.35

20

0.85

30

0.1 x 10–4

0.2 x 10–4

Unthrottled, please see diagrams starting on 10

Internet: www.festo.com/catalogue/...

Subject to change – 2008/04

Swivel modules DSM

Technical data DSM-6 … 10

Weights [g]

Size

6

8

10

90°

180°

240°

45

78

–

78

140

–

140

140

140

• Fixed stopp

• Position sensingg

90°

180°

240°

50

50

–

85

85

–

149

149

149

• Fixed stopp

• Adjustable swivel angle

180°

200°

70

–

140

–

–

240

• Fixed stopp

• Position sensingg

• Adjustable swivel angle

180°

200°

85

–

155

–

–

255

90°

180°

240°

51

51

–

85

85

–

150

150

150

• Fixed stopp

• Position sensingg

90°

180°

240°

56

56

–

92

92

–

159

159

159

• Fixed stopp

• Adjustable swivel angle

180°

200°

76

–

147

–

–

250

• Fixed stopp

• Position sensingg

• Adjustable swivel angle

180°

200°

91

–

162

–

–

265

Spigot shaft

• Fixed stopp

Flanged shaft

• Fixed stopp

2008/04 – Subject to change

Internet: www.festo.com/catalogue/...

9

Swivel modules DSM

Technical data DSM-6 … 10

Materials

Sectional view

1

2

3

Swivel module

1

2

3

–

–

–

Shaft

Rotary vane

Housing

Screws

Seals

Note on materials

Stainless steel

Plastic, glass fibre reinforced

Anodised aluminium

Galvanised steel

Polyurethane

Free of copper and PTFE

Max. permissible mass moment of inertia

Example illustrating the use of the diagrams

A DSM-25-270-P swivel module is to

be used to rotate a gripper with load

through 180° in 0.4 s. The mass

moment of inertia of the gripper and

mass is 4.5 x 10–4 kgm2.

Question:

Is the value for the mass moment of

inertia still permissible?

DSM-8

J [kgm2 x10-4]

J [kgm2 x10-4]

Mass moment of inertia J as a function of swivel time t

DSM-6

If the permissible mass moment of

inertia had been exceeded in this

example, it would be necessary to

reduce the angular velocity by means

of flow control valves, or to equip the

DSM-25 with shock absorbers.

Answer:

The graph on page 23 indicates that

the permissible mass moment of inertia is 6.5 x 10–4 kgm2 for a 180°

angle of rotation. This means that the

swivel actuator can be used without

flow control valves!

t [s]

t [s]

DSM-10

J [kgm2 x10-4]

90°

180°

240°

t [s]

10

Internet: www.festo.com/catalogue/...

Subject to change – 2008/04

Swivel modules DSM

Technical data DSM-6 … 10

Download CAD data www.festo.com

Dimensions

With spigot shaft and fixed stop

Spigot design for swivel module

DSM-10

Shaft position

-H-

Note

For swivel angle tolerance, table

below. Compressed air connections

are shown at the bottom in the

drawing.

Size

B1

B2

B3

B4

D1

∅

g7

D2

∅

D3

∅

D4

∅

H12

D5

D6

D7

∅

H12

D8

∅

D9

∅

H12

D10

EE

6

8

10

10

12.8

15.9

25

31

38

30

38

47

17

20

26

4

5

6

8

9

12

14

16

19

3.2

3.2

4.3

M3

M3

M4

M2

M2.5

M3

40

50

62

29.4

37.4

46.4

3.5

3.5

4.5

M2

M2

M2.5

M3

M3

M3

Size

L1

L2

L3

L4

L5

L6

L7

L8

L9

T1

T2

ß

Swivel angle tolerance

3

3.5

4.5

0/+5°

0/+5°

0/+5°

[mm]

[mm]

6

8

10

h12

43

50

61

2008/04 – Subject to change

13

16

19.6

10

13

16

2

2

2

9.8

11.3

14.3

21

23

28.4

5

6

8

6

6.5

7.5

3

3

4

3.5

4.5

–

4

4.3

5

Internet: www.festo.com/catalogue/...

11

Swivel modules DSM

Technical data DSM-6 … 10

Download CAD data www.festo.com

Dimensions

With spigot shaft, fixed stop and position sensing

1 Proximity sensors not included

in scope of delivery. Observe

fitting space for proximity

sensors and cable.

2 Magnet position

Size

D8

∅

3 Max. tightening torque for

sensor bracket screws

Table below

D9

∅

L3

4 The flat or the woodruff key on

the shaft indicates the position

of the rotary vane

L4

L5

L6

L7

[mm]

6

8

10

12

Tightening torque

[Nm]

29.4

37.4

46.4

17.3

19.3

22.3

4

4

4

2

2

2

Internet: www.festo.com/catalogue/...

9.8

11.3

14.3

21

23

28

19.5

19.5

19.5

0.19

0.32

0.44

Subject to change – 2008/04

Swivel modules DSM

Technical data DSM-6 … 10

Download CAD data www.festo.com

Dimensions

With spigot shaft, fixed stop and adjustable swivel angle

without orifice and cover

-H-

Note

The swivel angle is infinitely

adjustable over the entire swivel

range.

Size 6 mm can only be adjusted

symmetrically to the centre.

1 Supply ports

2 Locking screw for clamping

the stop

3 End position adjustment

4 Lock nut for end position

adjustment

5 Infinitely adjustable stops

Size

B1

B2

B3

B4

D1

∅

g7

D2

∅

D3

∅

D4

∅

H12

D5

D6

D7

∅

H12

D8

∅

D9

∅

H12

D18

∅

EE

6

8

10

10

12.8

15.9

25

31

38

30

38

47

17

20

26

4

5

6

8

9

12

14

16

19

3.2

3.2

4.3

M3

M3

M4

M2

M2.5

M3

40

50

62

29.4

37.4

46.4

3.5

3.5

4.5

22

26

35.8

M3

M3

M3

Size

L1

L2

L3

L4

L5

L6

L7

L8

L9

T1

ß

Max. swivel

angle

Precision

adjustment

both ends

52

64

76

13

16

19.6

10

13

16

2

2

2

9.8

11.3

14.3

21

23

28.4

17.8

24.9

28.2

6

6.5

7.5

3

3

4

3.5

4.5

–

4

5

5.5

180°+5°

180°+5°

200°+5°

+1°/–5°

+1°/–5°

+1°/–5°

[mm]

[mm]

6

8

10

With spigot shaft, fixed stop, adjustable swivel angle and position sensing

1 Sensors not included in

scope of delivery. Observe

fitting space for proximity

sensors and cable

2 Magnet position

Size

3 See table below for max.

tightening torque for sensor

bracket screws

4 The flat or the woodruff key on

the shaft indicates the position

of the rotary vane

D8

∅

D9

L1

L3

L4

L5

L6

L7

Tightening torque

29.4

37.4

46.4

17.3

19.3

22.3

68.5

80

91.5

4

4

4

2

2

2

9.8

11.3

14.3

21

23

28.4

19.5

19.5

19.5

0.19

0.32

0.44

[mm]

6

8

10

[Nm]

2008/04 – Subject to change

Internet: www.festo.com/catalogue/...

13

Swivel modules DSM

Technical data DSM-6 … 10

Download CAD data www.festo.com

Dimensions

With fixed stop and flanged shaft

1 Supply ports

2 Mark indicating rotary vane

position

Size

B1

B2

B3

B4

D1

∅

D2

∅

g7

D3

∅

f8

D4

∅

D5

D6

D7

∅

H12

D8

∅

D9

∅

H12

D10

∅

D11

D12

∅

H13

D13

∅

6

8

10

10

12.8

15.9

25

31

38

30

38

47

17

20

26

8

9

10

8

11

11

14

16

19

3.2

3.2

4.3

M3

M3

M4

M2

M2.5

M3

40

50

62

29.4

37.4

46.4

3.5

3.5

4.5

23

27

30

M3

M3

M3

3.4

3.4

3.4

16

21

21

Size

D14

EE

L1

L2

L3

L4

L5

L6

L7

L8

L9

L10

L11

T1

ß

Swivel angle

tolerance

M2

M2

M2.5

M3

M3

M3

39.5

43.5

53

30

34

41.4

7.5

7.5

9.6

2

2

2

9.8

11.3

14.3

21

23

28.4

5

6

8

6

6.5

7.5

3

3

4

3

3

3

1.5

1.5

1.6

4

4.3

5

3

3.5

4.5

0/+5°

0/+5°

0/+5°

[mm]

[mm]

6

8

10

With flanged shaft, fixed stop and position sensing

2 Magnet position

3 Max. tightening torque for

sensor bracket screw

Table below

1 Proximity sensors not

included in scope of delivery.

Observe fitting space for

proximity sensors and cable

Size

[mm]

6

8

10

14

D8

D9

∅

∅

29.4

37.4

46.4

17.3

19.3

22.3

L1

L3

L4

L5

L6

L7

Tightening torque

50

52

59.5

4

4

4

2

2

2

9.8

11.3

14.3

21

23

28.4

19.5

19.5

19.5

0.19

0.32

0.44

[Nm]

Internet: www.festo.com/catalogue/...

Subject to change – 2008/04

Swivel modules DSM

Technical data DSM-6 … 10

Download CAD data www.festo.com

Dimensions

With flanged shaft, fixed stop and adjustable swivel angle

without orifice and cover

-H-

Note

The swivel angle is infinitely

adjustable over the entire swivel

range.

Size 6 mm can only be adjusted

symmetrically to the centre.

1 Supply ports

2 Locking screw for clamping

the stop

3 End position adjustment

4 Lock nut for end position

adjustment

5 Infinitely adjustable stops

Size

B1

B2

B3

B4

D1

∅

D2

∅

g7

D3

∅

f8

D4

∅

H12

D5

D6

D7

∅

H12

D8

∅

6

8

10

10

12.8

15.9

25

31

38

30

38

47

17

20

26

8

9

10

8

11

11

14

16

19

3.2

3.2

4.3

M3

M3

M4

M2

M2.5

M3

40

50

62

29.4

37.4

46.4

Size

D10

∅

D11

D12

∅

H13

D13

∅

D18

∅

EE

L1

L2

L3

L4

[mm]

D9

∅

H12

6

8

10

3.5

3.5

4.5

23

27

30

M3

M3

M3

3.4

3.4

3.4

16

21

21

22

26

35.8

M3

M3

M3

48

58

68

9.5

9.5

11.6

8

8

10

2

2

2

Size

L5

L6

L7

L8

L9

L10

L11

ß

Max.

swivel angle

Precision

adjustment

both ends

9.8

11.3

14.3

21

23

28.4

17.8

24.9

28.2

6

6.5

7.5

3

3

4

3

3

3

1.5

1.5

1.6

4

5

5.5

180° +5°

180° +5°

200° +5°

+1°/–5°

+1°/–5°

+1°/–5°

[mm]

[mm]

6

8

10

2008/04 – Subject to change

Internet: www.festo.com/catalogue/...

15

Swivel modules DSM

Technical data DSM-6 … 10

Download CAD data www.festo.com

Dimensions

With flanged shaft, fixed stop, adjustable swivel angle and position sensing

1 Proximity sensors not included

in scope of delivery. Observe

fitting space for proximity

sensors and cable.

2 Magnet position

Size

-H-

3 Max. tightening torque for

sensor bracket screws

Table below

Note

The swivel angle is infinitely

adjustable over the entire swivel

range.

Size 6 mm can only be adjusted

symmetrically to the centre.

D8

∅

D9

∅

L1

L3

L4

L5

L6

L7

Tightening

torque

[Nm]

29.4

37.4

46.4

17.3

19.3

22.3

65

73.5

83

4

4

4

2

2

2

9.8

11.3

14.3

21

23

28.4

19.5

19.5

19.5

0.19

0.32

0.44

[mm]

6

8

10

16

Internet: www.festo.com/catalogue/...

Subject to change – 2008/04

Swivel modules DSM

Technical data DSM-6 … 10

Ordering data

Swivel module

Key features

Max. swivel angle

Size

[mm]

Part No.

Type

• Fixed stop

90°

6

8

10

6

8

10

10

6

8

10

6

8

10

10

6

8

10

173 188

173 190

173 192

173 189

173 191

173 193

173 194

173 195

173 197

173 199

173 196

173 198

173 200

173 201

175 827

175 828

175 829

DSM-6-90-P

DSM-8-90-P

DSM-10-90-P

DSM-6-180-P

DSM-8-180-P

DSM-10-180-P

DSM-10-240-P

DSM-6-90-P-A

DSM-8-90-P-A

DSM-10-90-P-A

DSM-6-180-P-A

DSM-8-180-P-A

DSM-10-180-P-A

DSM-10-240-P-A

DSM-6-180-P-FF

DSM-8-180-P-FF

DSM-10-240-P-FF

6

8

10

175 830

175 831

175 832

DSM-6-180-P-A-FF

DSM-8-180-P-A-FF

DSM-10-240-P-A-FF

6

8

10

6

8

10

10

6

8

10

6

8

10

10

6

8

10

185 928

185 934

185 940

185 929

185 935

185 941

185 942

185 930

185 936

185 943

185 931

185 937

185 944

185 945

185 932

185 938

185 946

DSM-6-90-P-FW

DSM-8-90-P-FW

DSM-10-90-P-FW

DSM-6-180-P-FW

DSM-8-180-P-FW

DSM-10-180-P-FW

DSM-10-240-P-FW

DSM-6-90-P-A-FW

DSM-8-90-P-A-FW

DSM-10-90-P-A-FW

DSM-6-180-P-A-FW

DSM-8-180-P-A-FW

DSM-10-180-P-A-FW

DSM-10-240-P-A-FW

DSM-6-180-P-FF-FW

DSM-8-180-P-FF-FW

DSM-10-240-P-FF-FW

6

8

10

185 933

185 939

185 947

DSM-6-180-P-A-FF-FW

DSM-8-180-P-A-FF-FW

DSM-10-240-P-A-FF-FW

Spigot shaft

180°

• Fixed stop

• Position sensing

240°

90°

180°

• Fixed stop

• Adjustable

swivel angle

j

g

240°

180°

200°

• Fixed stop

• Position sensingg

• Adjustable swivel angle

180°

• Fixed stop

90°

200°

Flanged shaft

180°

• Fixed stop

• Position sensing

240°

90°

180°

• Fixed stop

• Adjustable

swivel angle

j

g

240°

180°

200°

• Fixed stop

• Position sensingg

• Adjustable swivel angle

2008/04 – Subject to change

180°

200°

Internet: www.festo.com/catalogue/...

17

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Peripherals overview DSM-12 … 40

5

2

1

4

2

3

2

1

aJ

1

2

3

9

1

8

aJ

7

9

6

Accessories

1

2

3

4

5

6

7

8

9

aJ

18

Shock absorber retainer

DSM-…-CL/CR

Shock absorber

YSR

Mounting kit

WSM-…-J-M…

Proximity sensor, inductive

SIEN

Connecting cable

NEBU

Mounting plate

HSM

Push-on flange

FWSR

Freewheel unit

FLSM

One-way flow control valve

GRLA

Push-in fitting

QS

Brief description

Page/Internet

For end position adjustable at left, right or both ends

Expandable for swivel module DSM-…-P/DSM-…-P-FW, replaces the fixed stop

Self-adjusting shock absorbers in the end positions

30

For mounting inductive proximity sensors SIEN

34

For end position sensing, available with plug or cable

34

For inductive proximity sensors with plug

34

For foot or flange mounting

31

Accessory for swivel module DSM with spigot shaft

32

Only in conjunction with swivel module DSM with spigot shaft

28

To regulate speed

34

For connecting compressed air tubing with standard external diameters

quick star

Internet: www.festo.com/catalogue/...

34

Subject to change – 2008/06

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Type codes DSM-12 … 40

u

DSM

—

25

—

270

—

P

—

FW

—

CL

Type

Double-acting

DSM

Swivel module

Size [mm]

Max. swivel angle [°], adjustable

Cushioning

P

Non-adjustable at either end

Shaft

FW

Spigot shaft

Flanged shaft

Fixed stop/shock absorber

CL

CR

CC

Fixed stop

Shock absorber on left

Shock absorber on right

Shock absorbers at both ends

2008/06 – Subject to change

Internet: www.festo.com/catalogue/...

19

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Technical data DSM-12 … 40

Function

-N-W-

Size

12 … 40 mm

www.festo.com

General technical data

Size

12

Pneumatic connection

Design

Cushioning

16

25

32

40

without shock

absorber

with shock absorber

(CR/CL)

with two shock

absorbers (CC)

without shock

absorber

with shock absorber

[°]

M5

Gx

Rotary vane

Flexible cushioning rings/plates at both ends; self-adjustable at one end;

self-adjustable at both ends

Via female thread

Any

0 … 270

0 … 270

0 … 270

0 … 270

0 … 270

[°]

0 … 254

0 … 254

0 … 258

0 … 258

0 … 255

[°]

0 … 238

0 … 238

0 … 246

0 … 246

0 … 240

[Hz]

2

[Hz]

without shock

absorber

with shock absorber

Air consumption at max. swivel angle and 6 bar1)

[°]

1.5

1

0.7

Without shock absorber –5 … +1°; with shock absorber 30

1.8 … 2.1

1.3 … 2.1

1.1 … 1.9

0.9 … 1.7

1.4 … 2.1

[°]

[cm3]

13

82

12

163

10

288

12.5

632

15

1,168

12

16

25

32

40

Type of mounting

Assembly position

Max. swivel angle

Max. permissible frequency

((with max. swivel angle)

g )

Swivel angle adjustment

Cushioning angle

1) Theoretical values

-H- Note: This product conforms with the ISO 1179-1 standard and the ISO 228-1 standard.

Operating and environmental conditions

Size

Operating medium

Operating pressure

Temperature range1)

CE symbol

1)

[bar]

[°C]

Note operating range of proximity sensors

Forces and torques

Size

Torque at 6 bar

Max. perm. radial load on drive shaft

Max. perm. axial load on drive shaft

Max. perm. mass moment of inertia

on the drive shaft1)

1)

20

Filtered compressed air, lubricated or unlubricated

2 … 10

1.5 … 10

– 10 … +60

Atex

without shock

absorber

with shock absorber

12

16

25

32

40

[Nm]

[N]

[N]

[kgm2]

1.25

45

18

0.35 x 10–4

2.5

75

30

0.7 x 10–4

5

120

50

1.1 x 10–4

10

200

75

1.1 x 10–4

20

350

120

2.4 x 10–4

[kgm2]

7 x 10–4

12 x 10–4

16 x 10–4

21 x 10–4

40 x 10–4

Unthrottled, please see diagrams starting on 23

Internet: www.festo.com/catalogue/...

Subject to change – 2008/06

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Technical data DSM-12 … 40

Weights [g]

Size

12

16

25

32

40

250

450

690

1,380

2,600

• Shock absorber on left

• Adjustable swivel angle

300

510

730

1,480

2,830

• Shock absorber on right

g

• Adjustable swivel angle

300

510

730

1,480

2,830

• Shock absorbers on both sides

• Adjustable swivel angle

300

510

730

1,480

2,830

250

450

690

1,380

2,600

• Shock absorber on left

• Adjustable swivel angle

300

510

730

1,480

2,830

• Shock absorber on right

g

• Adjustable swivel angle

510

510

730

1,480

2,830

• Shock absorbers on both sides

• Adjustable swivel angle

300

510

730

1,480

2,830

Spigot shaft

• Fixed stopp

• Adjustable swivel angle

Flanged shaft

• Fixed stopp

• Adjustable swivel angle

2008/06 – Subject to change

Internet: www.festo.com/catalogue/...

21

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Technical data DSM-12 … 40

Materials

Sectional view

2

1

3

Swivel module

Anodised aluminium

Nickel-plated steel

Plastic, glass fibre reinforced

Galvanised steel

Stainless steel

Plastic, glass fibre reinforced

Polyurethane

Free of copper and PTFE

Cushioning (cushioning angle w as a function of swivel time t)

Fixed stop

Integrated shock absorber

w [°]

Housing, stop lever

Shaft

Rotary vane

Fixed stops / screws

Stop screws

Cap

Seals

Note on materials

w [°]

1

2

3

–

–

–

–

–

t [ms]

t [ms]

Max. permissible mass moment of inertia

Example illustrating the use of the diagrams

A DSM-25-270-P swivel module is to

be used to rotate a gripper with load

through 180° in 0.4 s. The mass

moment of inertia of the gripper and

mass is 4.5 x 10–4 kgm2.

Question:

Is the value for the mass moment of

inertia still permissible?

22

Answer:

The graph on page 23 indicates that

the permissible mass moment of inertia is 6.5 x 10–4 kgm2 for a 180°

angle of rotation. This means that the

swivel actuator can be used without

flow control valves!

Internet: www.festo.com/catalogue/...

If the permissible mass moment of

inertia had been exceeded in this

example, it would be necessary to

reduce the angular velocity by means

of flow control valves, or to equip the

DSM-25 with shock absorbers.

-H-

Note

In the diagrams, swivelling time is

specified for CL/CR/CC variants up

to the point when the stop lever

meets the shock absorber. The

specified cushioning time of the

shock absorber must be added in

order to obtain total swivelling time.

Subject to change – 2008/06

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Technical data DSM-12 … 40

Mass moment of inertia J as a function of swivel time t

Without shock absorber

DSM-12-270-P

With shock absorber

DSM-12-270-P-CL/CR/CC

J [kgm2 x10-4]

J [kgm2 x10-4]

Max. permissible mass moment of inertia: 80 x 10-4 kgm2

Cushioning time, shock absorbers YSR-5-5-C: approx. 0.1 s

t [s]

t [s]

DSM-16-270-P

DSM-16-270-P-CL/CR/CC

J [kgm2 x10-4]

J [kgm2 x10-4]

Max. permissible mass moment of inertia: 200 x 10-4 kgm2

Cushioning time, shock absorbers YSR-7-5-C: approx. 0.1 s

t [s]

t [s]

DSM-25-270-P

DSM-25-270-P-CL/CR/CC

J [kgm2 x10-4]

J [kgm2 x10-4]

Max. permissible mass moment of inertia: 280 x 10-4 kgm2

Cushioning time, shock absorbers YSR-7-5-C: approx. 0.1 s

t [s]

t [s]

90°

180°

270°

2008/06 – Subject to change

Internet: www.festo.com/catalogue/...

23

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Technical data DSM-12 … 40

Mass moment of inertia J as a function of swivel time t

Without shock absorber

DSM-32-270-P

With shock absorber

DSM-32-270-P-CL/CR/CC

J [kgm2 x10-4]

J [kgm2 x10-4]

Max. permissible mass moment of inertia: 500 x 10-4 kgm2

Cushioning time, shock absorbers YSR-8-8-C: approx. 0.25 s

t [s]

t [s]

DSM-40-270-P

DSM-40-270-P-CL/CR/CC

J [kgm2 x10-4]

J [kgm2 x10-4]

Max. permissible mass moment of inertia: 1200 x 10-4 kgm2

Cushioning time, shock absorbers YSR-12-12-C: approx. 0.3 s

t [s]

t [s]

90°

180°

270°

24

Internet: www.festo.com/catalogue/...

Subject to change – 2008/06

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Technical data DSM-12 … 40

Download CAD data www.festo.com

Dimensions

With spigot shaft and fixed stop

without cap

1 Woodruff key position at 0°

2 Supply ports

Size

3 Locking screw for clamping the

stop

4 Manual operation

(internal hex)

5 End position adjustment

6 Lock nut for end position

adjustment

7 Infinitely adjustable stops

B1

B2

B3

B4

D1

∅

g7

D2

∅

D3

∅

f8

D4

D5

D6

D7

∅

D8

∅

D9

∅

D10

E1

H1

12

16

25

32

40

19.8

23.5

28

35.5

43.8

48

57

65

85

105

59

70

83

105

130

30

40

40

60

80

8

10

12

16

20

15

18

20

27

36

24

28

30

42

52

M3

M3

M4

M5

M6

M4

M5

M6

M8

M10

M3

M3

M3

M3

M3

78

91

106

135

168

58

69

82

104

128

9

12.5

13

16.5

23.5

M4

M5

M5

M5

M6

M5

M5

M5

Gx

Gx

29.5

35

41.5

52.5

65

Size

L1

L2

L3

L4

L5

L6

L7

L8

T1

T2

T3

ß1

ß2

Woodruff key to

DIN 68851)

77.5

90.8

105.5

139.5

171.5

24.5

28

36.5

51

62

20

23

30

40

50

3

2.6

4

8

8

10.3

13

15.2

19.2

23.7

68.3

81.2

97.5

127.1

155.5

5

6.5

7.5

9.5

12

16.5

20.2

23.5

30.5

36

9

9

10

12.5

16

8

8

10

12

15

7

8

10

13

17

6

8

8

10

10

A2x2x16

A3x3x18

A4x4x25

A5x5x36

A6x6x45

[mm]

[mm]

12

16

25

32

40

max.

8.8

11.2

13.5

18

22.5

1) included in scope of delivery

-H- Note: This product conforms with the ISO 1179-1 standard and the ISO 228-1 standard.

2008/06 – Subject to change

Internet: www.festo.com/catalogue/...

25

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Technical data DSM-12 … 40

Download CAD data www.festo.com

Dimensions

With fixed stop and flanged shaft

without cap

1 Supply ports

2 Flanged shaft with throughhole

3 Locking screw for clamping the

stop

4 Manual operation

(external hex)

5 End position adjustment

6 Lock nut for end position

adjustment

7 Infinitely adjustable stops

8 The position of the marking

corresponds to the position of

the stop.

B1

B2

B3

B4

B5

D1

∅

D2

∅

f8

D3

∅

f8

D4

D5

D6

∅

D8

∅

D9

∅

∅

D11

12

16

25

32

40

19.8

23.5

28

35.5

43.8

48

57

65

85

105

59

70

83

105

130

30

40

40

60

80

25

28

35

45

54

15

18

20

27

36

14

16

20

28

36

24

28

30

42

52

M5

M5

Gx

Gx

G¼

M4

M5

M6

M8

M10

M3

M3

M3

M3

M3

78

91

106

135

168

58

69

82

104

128

9

12.5

13

16.5

23.5

33

38

46

60

70

M3

M4

M5

M6

M8

Size

D12

∅

E1

H1

L1

L2

L3

L4

L5

L6

L7

L8

L9

T3

ß1

ß2

ß3

3.4

4.5

5.5

6.6

9

M5

M5

M5

Gx

Gx

29.5

35

41.5

52.5

65

67.3

79

90

115.8

143.8

13

15

19.5

27

33

11

13

16.5

23

28

3

2.6

4

8

8

10.3

13

15.2

19.2

23.7

3

4

4.5

6

7.5

5

6.5

7.5

9.5

12

16.5

20.2

23.5

30.5

36

2

2

3

4

5

8

8

10

12

15

7

8

10

13

17

8

11

13

13

19

2.5

3

4

5

8

Size

[mm]

[mm]

12

16

25

32

40

-H- Note: This product conforms with the ISO 1179-1 standard and the ISO 228-1 standard.

26

Internet: www.festo.com/catalogue/...

Subject to change – 2008/06

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Technical data DSM-12 … 40

Ordering data

Swivel module

Key features

Max. swivel angle

Size

[mm]

Part No.

Type

• Fixed stop

• Adjustable swivel angle

270°

12

16

25

32

40

159 540

159 541

158 959

152 593

152 594

DSM-12-270-P

DSM-16-270-P

DSM-25-270-P

DSM-32-270-P

DSM-40-270-P

• Shock absorber on left

• Adjustable swivel angle

254°

254°

258°

258°

255°

12

16

25

32

40

164 321

163 000

163 002

163 004

163 006

DSM-12-270-P-CL

DSM-16-270-P-CL

DSM-25-270-P-CL

DSM-32-270-P-CL

DSM-40-270-P-CL

• Shock absorber on right

• Adjustable swivel angle

254°

254°

258°

258°

255°

12

16

25

32

40

164 322

163 001

163 003

163 005

163 007

DSM-12-270-P-CR

DSM-16-270-P-CR

DSM-25-270-P-CR

DSM-32-270-P-CR

DSM-40-270-P-CR

• Shock absorbers on both sides

• Adjustable swivel angle

238°

238°

246°

246°

240°

12

16

25

32

40

164 323

161 746

161 747

161 748

161 749

DSM-12-270-P-CC

DSM-16-270-P-CC

DSM-25-270-P-CC

DSM-32-270-P-CC

DSM-40-270-P-CC

• Fixed stop

• Adjustable swivel angle

270°

12

16

25

32

40

157 657

157 658

157 659

157 660

157 661

DSM-12-270-P-FW

DSM-16-270-P-FW

DSM-25-270-P-FW

DSM-32-270-P-FW

DSM-40-270-P-FW

• Shock absorber on left

• Adjustable swivel angle

254°

254°

258°

258°

255°

12

16

25

32

40

170 080

170 083

170 086

170 089

170 092

DSM-12-270-P-FW-CL

DSM-16-270-P-FW-CL

DSM-25-270-P-FW-CL

DSM-32-270-P-FW-CL

DSM-40-270-P-FW-CL

• Shock absorber on right

• Adjustable swivel angle

254°

254°

258°

258°

255°

12

16

25

32

40

170 081

170 084

170 087

170 090

170 093

DSM-12-270-P-FW-CR

DSM-16-270-P-FW-CR

DSM-25-270-P-FW-CR

DSM-32-270-P-FW-CR

DSM-40-270-P-FW-CR

• Shock absorbers at both ends

• Adjustable swivel angle

238°

238°

246°

246°

240°

12

16

25

32

40

170 079

170 082

170 085

170 088

170 091

DSM-12-270-P-FW-CC

DSM-16-270-P-FW-CC

DSM-25-270-P-FW-CC

DSM-32-270-P-FW-CC

DSM-40-270-P-FW-CC

Spigot shaft

Flanged shaft

2008/06 – Subject to change

Internet: www.festo.com/catalogue/...

27

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Accessories

Free wheel unit FLSM

-H-

Material:

Housing: Anodised aluminium

Shaft: ∅ 6, 8 steel

∅ 10 … 40 hardened steel

Sleeve: ∅ 6, 8 steel

∅ 10 … 40 hardened steel

The minimum possible rotation

angle is 3°.

Switching accuracy is, however,

dependent on speed and load.

Note

Dimensions

FLSM-6/8

FLSM-10

FLSM-12 … 40

28

Internet: www.festo.com/catalogue/...

Subject to change – 2008/06

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Accessories

Dimensions and ordering data

For size

B3

B4

[mm]

D3

∅

h8

D4

±0.15

D1

∅

g7

23

24

38

42

50

60

83

96

4

5

6

8

10

12

16

20

14

16

20

25

24

28

42

52

–

–

M2.5

M3

M3

M4

M5

M6

D5

M3

M3

M3

M3

M4

M6

M6

M8

D6

∅

±0.3

L1

28

30

43

48.5

60

70

95

110

85.8

94.5

101

125

137

152

197.8

244.5

6

8

10

12

16

25

32

40

29.5

37

45

55

65

80

100

120

For size

L9

T1

T2

T3

T4

Woodruff key

to DIN 6885

6

12.8

–

–

5

3.5

3

5

–

2

100

8

16

–

–

6

4.5

5

–

2

125

5

10

20.2

6.8

7

8

–

A2x2x12

2

160

12

24.5

5

8.8

9

8

–

A2x2x16

2

3300

16

27.4

7

11.2

9

10

–

A3x3x18

3 3

2

450

5

25

5

334

13.5

35

10

15

5

–

A4x4x25

5

2

650

5

332

48.5

5

18

12.5

5

15

5

–

A5x5x36

5 5 3

2

1 5500

40

558

22.5

5

16

15

5

–

A6x6x45

5

2

2 35

350

CRC1)

Weight

[mm]

1)

L2

36 ±0.1

37.5 ±0.1

30 ±0.1

37 ±0.4

34 ±0.4

34 ±0.4

42.8 ±0.4

54 ±0.4

L3

10.8

14

16.7

20

23

30

40

50

L4

10

13

–

–

–

–

–

–

L6

L8

+0.2

±0.1

2

2

3.5

3.5

3.5

3.5

7.2

6

43

44.5

40

47.3

47

49

60.8

77

Direction of rotation Part No.

Type

left-hand

right-hand

left-hand

right-hand

left-hand

right-hand

left-hand

right-hand

left-hand

right-hand

left-hand

right-hand

left-hand

right-hand

left-hand

right-hand

FLSM-6-L

FLSM-6-R

FLSM-8-L

FLSM-8-R

FLSM-10-L

FLSM-10-R

FLSM-12-L

FLSM-12-R

FLSM-16-L

FLSM-16-R

FLSM-25-L

FLSM-25-R

FLSM-32-L

FLSM-32-R

FLSM-40-L

FLSM-40-R

[g]

188 523

188 522

188 525

188 524

188 527

188 526

164 229

164 234

164 230

164 235

164 231

164 236

164 232

164 237

164 233

164 238

Corrosion resistance class 2 according to Festo standard 940 070

Components requiring moderate corrosion resistance. Externally visible parts with primarily decorative surface requirements which are in direct contact with a surrounding industrial atmosphere or media such as

cooling or lubricating agents

Direction of rotation

The freewheel unit blocks one of the

two possible swivel directions of the

DSM swivel module.

FLSM-…-R, right-hand (clockwise) rotation

1

FLSM-…-L, left-hand (counter-clockwise) rotation

1

1 Viewed towards drive shaft

2008/06 – Subject to change

Internet: www.festo.com/catalogue/...

29

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Accessories

Shock absorber retainer

DSM-…-CL/CR

Material:

Galvanised steel

Free of copper, PTFE and silicone

Dimensions

CL variants

CR variants

CC variants

Precision adjustment

1 Mounting thread for end

position sensing

2 Infinitely adjustable shock

absorber retainer for

adjustment of swivel angle

30

3 Locking screw for tightening

the shock absorber retainer

4 Cushioning angle

Internet: www.festo.com/catalogue/...

5 Cushioning length

6 Shock absorber at internal stop

in retainer

7 Precision adjustment

(not with DSM-12)

8 Shock absorber unscrewed

Subject to change – 2008/06

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Accessories

Dimensions and ordering data

For size

H1

[mm]

H2

R

max.

S

max.

12

16

25

32

40

18

22

19

27

41

48

60.8

68.3

82

101.5

48

58

61

81

108

For size

W3

W4

[mm]

max.

Woodruff key

to

DIN 6885

12

238°

3

13°

3

A2x2x16

2

330

16

238°

3

12°

A3x3x18

3 3

2

550

25

5

246°

10°

A4x4x25

5

2

551

332

246°

12.5°

5

A5x5x36

5 5 3

2

95

40

240°

15°

5

A6x6x45

5

2

175

75

1)

4.5

5

5

8

12

CRC1)

Weight

T1

W1

W2

max.

max.

max.

8.8

11.2

13.5

18

22.5

254°

254°

258°

258°

255°

119°

119°

123°

123°

120°

For shock

absorbers

Part No.

Type

Left

Right

Left

Right

Left

Right

Left

Right

Left

Right

164 324

164 325

161 184

161 185

161 186

161 187

161 188

161 189

161 190

161 191

DSM-12-CL

DSM-12-CR

DSM-16-CL

DSM-16-CR

DSM-25-CL

DSM-25-CR

DSM-32-CL

DSM-32-CR

DSM-40-CL

DSM-40-CR

[g]

Corrosion resistance class 2 according to Festo standard 940 070

Components requiring moderate corrosion resistance. Externally visible parts with primarily decorative surface requirements which are in direct contact with a surrounding industrial atmosphere or media such as

cooling or lubricating agents

Mounting plate HSM

Material:

Aluminium

Dimensions and ordering data

For size

B6

D16

[mm]

∅

D17

∅

H2

L12

L13

T4

CRC1)

Weight

[g]

Part No.

Type

12

16

25

32

40

4.5

5.5

6.6

9

11

10

10

10

15

20

84

98

110

145

180

72

84

95

125

155

4.6

5.7

6.8

9

11

2

2

2

2

2

48

80

94

246

459

165 571

165 572

165 573

165 574

165 575

HSM-12

HSM-16

HSM-25

HSM-32

HSM-40

1)

20

28

30

40

45

8

10

11

15

18

Corrosion resistance class 2 according to Festo standard 940 070

Components requiring moderate corrosion resistance. Externally visible parts with primarily decorative surface requirements which are in direct contact with a surrounding industrial atmosphere or media such as

cooling or lubricating agents

2008/06 – Subject to change

Internet: www.festo.com/catalogue/...

31

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Accessories

Push-on flange FWSR

for size 6/8

Material:

Wrought aluminium alloy, anodised

Free of copper, PTFE and silicone

1 Threaded pin, M3x5 DIN 916

Dimensions and ordering data

For size

B5

D11

D12

∅

H13

[mm]

D13

∅

g7

D14

∅

6

8

8

11

23

27

1)

16

21

M3

M3

3.4

3.4

D15

∅

L9

L10

L11

L12

CRC1)

Weight

Part No.

Type

185 948

185 949

FWSR-6

FWSR-8

[g]

10

12

10.5

12.5

3

3

1.5

1.5

45

51

2

2

6

8

Corrosion resistance class 2 according to Festo standard 940 070

Components requiring moderate corrosion resistance. Externally visible parts with primarily decorative surface requirements which are in direct contact with a surrounding industrial atmosphere or media such as

cooling or lubricating agents

Push-on flange FWSR

for size 10 … 40

Material:

Wrought aluminium alloy, anodised

Free of copper, PTFE and silicone

-H-

Note

The swivel module shown in the

dimensional drawing corresponds

to variants with size 12 to 40 mm.

Dimensions and ordering data

For size

B5

D11

D12

∅

H13

[mm]

D13

∅

g7

D14

∅

10

21

M3

3.4

11

30

12

22

3

1.6

68.6

2

12

25

M3

3.4

14

35

15

25

3

3

85.5

2

16

28

M4

4.5

16

40

17

28

5

3

98.8

25

35

M5

5.5

20

50

23

38

8

3

32

40

45

54

M6

M8

6.5

9

28

36

60

70

28

38

48

60

10

11

4

5

1)

32

D15

∅

L9

L10

L11

L12

CRC1)

Weight

Part No.

Type

14

32 798

FWSR-10

32

14 659

FWSR-12

2

51

13 239

FWSR-16

116.5

2

68

13 240

FWSR-25

151.5

186.5

2

2

180

300

13 241

14 656

FWSR-32

FWSR-40

[g]

Corrosion resistance class 2 according to Festo standard 940 070

Components requiring moderate corrosion resistance. Externally visible parts with primarily decorative surface requirements which are in direct contact with a surrounding industrial atmosphere or media such as

cooling or lubricating agents

Internet: www.festo.com/catalogue/...

Subject to change – 2008/06

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Accessories

Ordering data – Kits

For size

Remarks

Part No.

Type

6

8

10

For proximity

p

y sensor SME/SMT-10

/

173 205

173 206

173 207

Technical data Internet: wsm

WSM-6-SME-10

WSM-8-SME-10

WSM-10-SME-10

6

For swivel angle

g adjustment,

j

max. 180°

175 833

Technical data Internet: ksm

KSM-6

175 834

KSM-8

175 835

KSM-10

Ordering data – Kit accessories

For size

Remarks

Part No.

Type

6

8

10

6

8

10

375 098

375 099

375 100

258 568

385 259

365 902

DSM-6-180-P-A-FF

DSM-8-180-P-A-FF

DSM-10-240-P-A-FF

DIN 84-M2x25-4.8

DIN 84-M2x30-4.8

M2.5x321)

Cable length

[m]

Part No.

Technical data Internet: smt

Type

yp

2.5

0.3

0.3

0.3

2.5

525 915

525 916

526 675

173 220

173 218

SMT-10F-PS-24V-K2,5L-OE

SMT-10F-PS-24V-K0,3L-M8D

SMT-10F-PS-24V-K0,3Q-M8D

SMT-10-PS-SL-LED-24

SMT-10-PS-KL-LED-24

Cable length

[m]

Part No.

Technical data Internet: sme

Type

yp

0.3

2.5

2.5

2.5

2.5

0.3

0.3

525 914

525 913

526 672

173 210

173 211

173 212

173 213

SME-10F-DS-24V-K0,3L-M8D

SME-10F-DS-24V-K2,5L-OE

SME-10F-ZS-24V-K2,5L-OE

SME-10-KL-LED-24

SME-10-KQ-LED-24

SME-10-SL-LED-24

SME-10-SQ-LED-24

Mounting kit

End stop kit

8

10

1)

For swivel angle adjustment, max. 200°

Adapter

p for attachment of stopp kit KSM or mountingg kit

WSM-…-SME-10

Socket head screw for attachment of stopp kit KSM or mountingg kit WSM-…-SME-10

Screw similar to DIN 84

Ordering data – Proximity sensors for C-slot, magneto-resistive

Type

yp of mountingg

Switch

Electrical connection,,

output

connection direction

N/O contact

Insertable in the slot from

above,, flush with cylinder

y

profile

Insertable in the slot

lengthwise

PNP

PNP

Cable, 3-wire, in-line

Plug M8x1, 3-pin, in-line

Plug M8x1, 3-pin, lateral

Plug M8x1, 3-pin, in-line

Cable, 3-wire, in-line

Ordering data – Proximity sensors for C-slot, magnetic reed

Type

yp of mountingg

Switch

Electrical connection,,

output

connection direction

N/O contact

Insertable in the slot from

above,, flush with cylinder

y

profile

Insertable in the slot

lengthwise

g

2008/06 – Subject to change

Contactingg

Contactingg

Plug M8x1, 3-pin, in-line

Cable, 3-wire, in-line

Cable, 2-wire, in-line

Cable, 3-wire, in-line

Cable, 3-wire, lateral

Plug M8x1, 3-pin, in-line

Plug M8x1, 3-pin, lateral

Internet: www.festo.com/catalogue/...

33

-U- Type discontinued

Available up until 2008: Size 12 … 40

Swivel modules DSM

Accessories

Remarks

Part No.

Technical data Internet: ysr

Type

For shock absorber retainer DSM-…-CL/CR

/

158 981

160 272

34 571

34 572

YSR-5-5-C

YSR-7-5-C

YSR-8-8-C

YSR-12-12-C

Remarks

Part No.

Type

For inductive pproximityy sensors SIEN-M5

5

161 041

161 042

161 043

161 044

161 045

WSM-12-J-M5

WSM-16-J-M5

WSM-25-J-M5

WSM-32-J-M8

WSM-40-J-M8

Connection

Part No.

Technical data Internet: sien

Type

Cable

Plug

Cable

Plug

150 370

150 371

150 386

150 387

SIEN-M5B-PS-K-L

SIEN-M5B-PS-S-L

SIEN-M8B-PS-K-L

SIEN-M8B-PS-S-L

Electrical connection,, right

g

Cable length

[m]

Part No.

Technical data Internet: nebu

Type

yp

Straight

g socket,, M8x1,, 3-pin

3p

Cable,, open

p end,, 3-wire

3

Angled

g socket,, M8x1,, 3-pin

3p

Cable,, open

p end,, 3-wire

3

2.5

5

2.5

5

541 333

541 334

541 338

541 341

NEBU-M8G3-K-2.5-LE3

NEBU-M8G3-K-5-LE3

NEBU-M8W3-K-2.5-LE3

NEBU-M8W3-K-5-LE3

Material

Part No.

Technical data Internet: grla

Type

yp

Metal design

g

175 041

193 137

193 138

193 139

193 142

193 143

193 144

193 145

GRLA-M3-QS-3

GRLA-M5-QS-3-D

GRLA-M5-QS-4-D

GRLA-M5-QS-6-D

GRLA-x-QS-3-D

GRLA-x-QS-4-D

GRLA-x-QS-6-D

GRLA-x-QS-8-D

Ordering data – Shock absorbers

For size

12

16, 25

32

40

Ordering data – Mounting kits

For size

12

16

25

32

40

For inductive pproximityy sensors SIEN-M8

Ordering data – Proximity sensors, inductive

For size

Remarks

12,, 16,, 25

5

For mountingg kit WSM-…-J-M5

J 5

332,, 40

For mountingg kit WSM-…-J-M8

J

Ordering data – Connecting cables

Electrical connection,, left

Ordering data – One-way flow control valves

Connection

Thread

For tubing O.D.

For exhaust air

M3

M5

5

Gx

x

34

3

3

4

6

3

4

6

8

Internet: www.festo.com/catalogue/...

Subject to change – 2008/06

Product Range and Company Overview

A Complete Suite of Automation Services

Our experienced engineers provide complete support at every stage of your development process, including: conceptualization,

analysis, engineering, design, assembly, documentation, validation, and production.

Custom Automation Components

Complete custom engineered solutions

Custom Control Cabinets

Comprehensive engineering support

and on-site services

Complete Systems

Shipment, stocking and storage services

The Broadest Range of Automation Components

With a comprehensive line of more than 30,000 automation components, Festo is capable of solving the most complex

automation requirements.

Electromechanical

Electromechanical actuators, motors,

controllers & drives

Pneumatics

Pneumatic linear and rotary actuators,

valves, and air supply

PLCs and I/O Devices

PLC's, operator interfaces, sensors

and I/O devices

Supporting Advanced Automation… As No One Else Can!

Festo is a leading global manufacturer of pneumatic and electromechanical systems, components and controls for industrial automation,

with more than 12,000 employees in 56 national headquarters serving more than 180 countries. For more than 80 years, Festo has

continuously elevated the state of manufacturing with innovations and optimized motion control solutions that deliver higher performing,

more profitable automated manufacturing and processing equipment. Our dedication to the advancement of automation extends beyond

technology to the education and development of current and future automation and robotics designers with simulation tools, teaching

programs, and on-site services.

Quality Assurance, ISO 9001 and ISO 14001 Certifications

Festo Corporation is committed to supply all Festo products and services that will meet or exceed

our customers’ requirements in product quality, delivery, customer service and satisfaction.

To meet this commitment, we strive to ensure a consistent, integrated, and systematic approach

to management that will meet or exceed the requirements of the ISO 9001 standard for Quality

Management and the ISO 14001 standard for Environmental Management.

© Copyright 2008, Festo Corporation. While every effort is made to ensure that all dimensions and specifications are correct, Festo cannot guarantee that

publications are completely free of any error, in particular typing or printing errors. Accordingly, Festo cannot be held responsible for the same. For Liability and

Warranty conditions, refer to our “Terms and Conditions of Sale”, available from your local Festo office. All rights reserved. No part of this publication may be

reproduced, distributed, or transmitted in any form or by any means, electronic, mechanical, photocopying or otherwise, without the prior written permission of

Festo. All technical data subject to change according to technical update.

Printed on recycled paper at New Horizon Graphic, Inc., FSC certified as an environmentally friendly printing plant.

Festo North America

United States

Customer Resource Center

502 Earth City Expy., Suite 125

Earth City, MO 63045

Design and Manufacturing Operations

For ordering assistance, or to find

your nearest Festo Distributor,

Call:

1.800.99.FESTO

Fax:

1.800.96.FESTO

Email: customer.service@us.festo.com

For technical support,

Call:

1.866.GO.FESTO

Fax:

1.800.96.FESTO

Email: product.support@us.festo.com

Headquarters

Festo Corporation

395 Moreland Road

P.O. Box 18023

Hauppauge, NY 11788

www.festo.com/us

East: 395 Moreland Road, Hauppauge, NY 11788

Sales Offices

Appleton

N. 922 Tower View Drive, Suite N

Greenville, WI 54942

Boston

120 Presidential Way, Suite 330

Woburn, MA 01801

Chicago

1441 East Business Center Drive

Mt. Prospect, IL 60056

Central: 1441 East Business Center Drive, Mt. Prospect, IL 60056

Dallas

1825 Lakeway Drive, Suite 600

Lewisville, TX 75057

Detroit - Automotive Engineering Center

2601 Cambridge Court, Suite 320

Auburn Hills, MI 48326

New York

395 Moreland Road

Hauppauge, NY 11788

Silicon Valley

4935 Southfront Road, Suite F

Livermore, CA 94550

West: 4935 Southfront Road, Suite F, Livermore, CA 94550

Mexico

Canada

Headquarters

Festo Pneumatic, S.A.

Av. Ceylán 3, Col. Tequesquinahuac

54020 Tlalnepantla, Edo. de México

Call:

011 52 [55] 53 21 66 00

Fax:

011 52 [55] 53 21 66 65

Email:

festo.mexico@mx.festo.com

www.festo.com/mx

Headquarters

Festo Inc.

5300 Explorer Drive

Mississauga, Ontario L4W 5G4

Call:

1.905.624.9000

Fax:

1.905.624.9001

Email:

info.ca@ca.festo.com

www.festo.com/ca

Festo Worldwide

Argentina Australia Austria Belarus Belgium Brazil Bulgaria Canada Chile China Colombia Croatia Czech Republic Denmark

Estonia Finland France Germany Great Britain Greece Hong Kong Hungary India Indonesia Iran Ireland Israel Italy Japan

Latvia Lithuania Malaysia Mexico Netherlands New Zealand Norway Peru Philippines Poland Romania Russia Serbia Singapore

Slovakia Slovenia South Africa South Korea Spain Sweden Switzerland Taiwan Thailand Turkey Ukraine United States Venezuela

www.festo.com