CCP Contact Probes Co., Ltd.

advertisement

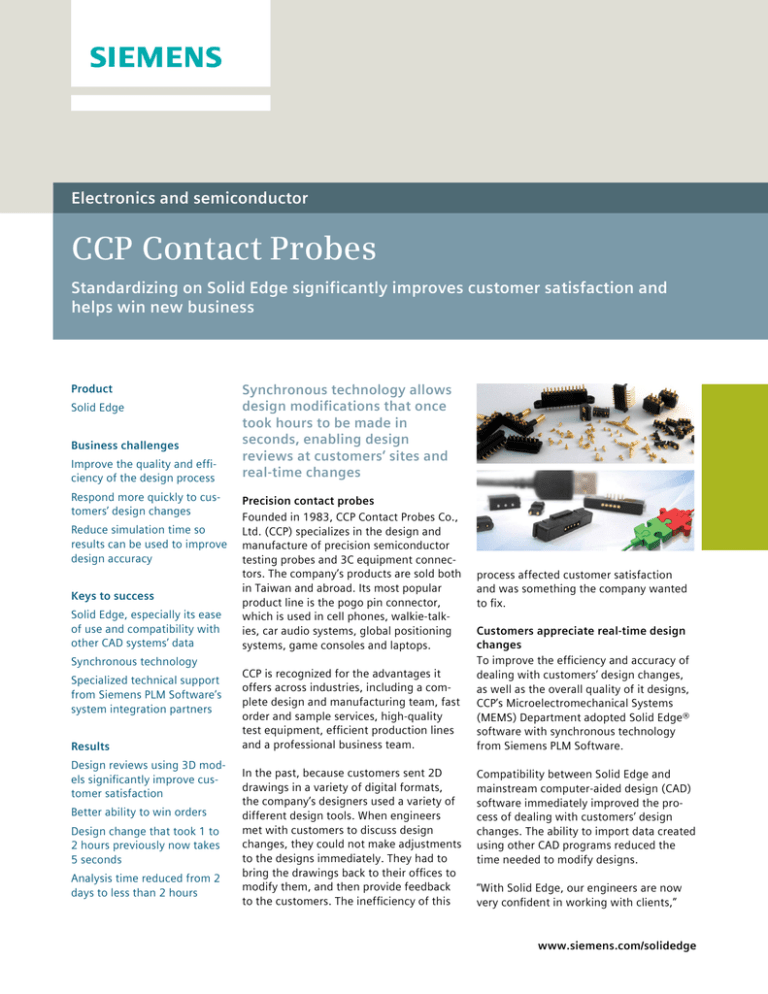

Electronics and semiconductor CCP Contact Probes Standardizing on Solid Edge significantly improves customer satisfaction and helps win new business Product Solid Edge Business challenges Improve the quality and efficiency of the design process Respond more quickly to customers’ design changes Reduce simulation time so results can be used to improve design accuracy Keys to success Solid Edge, especially its ease of use and compatibility with other CAD systems’ data Synchronous technology Specialized technical support from Siemens PLM Software’s system integration partners Results Design reviews using 3D models significantly improve customer satisfaction Better ability to win orders Design change that took 1 to 2 hours previously now takes 5 seconds Analysis time reduced from 2 days to less than 2 hours Synchronous technology allows design modifications that once took hours to be made in seconds, enabling design reviews at customers’ sites and real-time changes Precision contact probes Founded in 1983, CCP Contact Probes Co., Ltd. (CCP) specializes in the design and manufacture of precision semiconductor testing probes and 3C equipment connectors. The company’s products are sold both in Taiwan and abroad. Its most popular product line is the pogo pin connector, which is used in cell phones, walkie-talkies, car audio systems, global positioning systems, game consoles and laptops. CCP is recognized for the advantages it offers across industries, including a complete design and manufacturing team, fast order and sample services, high-quality test equipment, efficient production lines and a professional business team. In the past, because customers sent 2D drawings in a variety of digital formats, the company’s designers used a variety of different design tools. When engineers met with customers to discuss design changes, they could not make adjustments to the designs immediately. They had to bring the drawings back to their offices to modify them, and then provide feedback to the customers. The inefficiency of this process affected customer satisfaction and was something the company wanted to fix. Customers appreciate real-time design changes To improve the efficiency and accuracy of dealing with customers’ design changes, as well as the overall quality of it designs, CCP’s Microelectromechanical Systems (MEMS) Department adopted Solid Edge® software with synchronous technology from Siemens PLM Software. Compatibility between Solid Edge and mainstream computer-aided design (CAD) software immediately improved the process of dealing with customers’ design changes. The ability to import data created using other CAD programs reduced the time needed to modify designs. “With Solid Edge, our engineers are now very confident in working with clients,” www.siemens.com/solidedge “By using Solid Edge with synchronous technology, engineers can design the right products within a shorter time frame.” Dr. XuHoujun FAE and Sales Engineer CCP says Dr. XuHoujun, current FAE and sales engineer in the CCP Business Office, who was responsible for the selection of Solid Edge. “They cannot only discuss a design in depth, but can make any necessary changes to the 3D model, letting customers see their designs just as the actual product will look.” Xu notes that it is a very competitive industry, and suppliers such as CCP typically have only one chance to modify their designs. If there are more errors than that, the company will receive no more opportunities. To maintain these business relationships, modifying designs at the customer’s site and to representatives’ satisfaction, and letting them confirm the changes at that time, is critical. Switching to Solid Edge has dramatically improved the efficiency of both CCP and its customers. Dr. XuHoujun notes, “By using Solid Edge with synchro­nous technology, engineers can design the right prod­ucts within a shorter time frame.” Use of Solid Edge has helped CCP increase the accuracy of its molds, while reducing cost penalties caused by inaccuracies in mold designs. Overall, through the 3D modeling capabilities of Solid Edge, CCP has significantly improved customer satisfaction and become more competitive in winning orders. Huge time savings CCP also uses its models created using Solid Edge to support its finite element analysis (FEA) process. “With 3D modeling, finite element models can be analyzed in less time,” Xu adds. Previously, when working in 2D, design engineers had to create each finite element mesh one by one. Now, 3D models can be generated easily using Solid Edge, and these form the basis for the finite element meshes. As a result, analysis time has been reduced Use of Solid Edge has helped CCP increase the accuracy of its molds, while reducing cost penalties caused by inaccuracies in mold designs. Solutions/Services Solid Edge with synchronous technology www.siemens.com/solidedge Customer’s primary business CCP Contact Probes Co., Ltd. designs and manufactures precision semiconductor testing probes and 3C equipment connectors. www.pccp.com.tw Customer location New Taipei City Taiwan Partner CADEX Technology Co., Ltd. www.cadex.com.tw “With Solid Edge, our engineers are now very confident in working with clients. They can not only discuss a design in depth, but can make any necessary changes to the 3D model, letting customers see their designs just as the actual product will look.” Dr. XuHoujun FAE and Sales Engineer CCP from 2 days to less then 2 hours, accelerating the entire design process. The company finds synchronous technology to be another helpful tool in reducing the design cycle. Changing the angle of a pin in a contact probe, for example, used to take 1 to 2 hours using CAD systems with traditional history-based design processes. With the history-free synchronous technology, this change takes only 5 seconds. Technical support accelerated the benefits of Solid Edge During the implementation of Solid Edge, CCP benefited from technical support provided by CADEX Technology, a Siemens PLM Software partner. CADEX Technology provided training courses based on CCP’s own designs, and used TeamViewer® software for screen sharing to provide fast, online technical consultation. The channel partner was also very helpful to CCP during the time when the engineers were still learning the system. “Several deadline-sensitive proposals needed to be submitted to our customers at the time that we were still learning to use Solid Edge,” says Xu. “With help from the experts at CADEX Technology, our engineers were able to complete 6 time-critical proposals within 2 days, and we won those orders. We always hoped that the introduction of new software would not delay on our schedule. The help we got from Siemens PLM Software and CADEX was beyond our expectations.” In the future, CCP intends to expand the use of Solid Edge to other product development departments throughout the enterprise. Changing the angle of a pin in a contact probe, for example, used to take 1 to 2 hours....With the history-free synchronous technology, this change takes only 5 seconds. Siemens PLM Software Americas +1 314 264 8287 Europe +44 (0) 1276 413200 Asia-Pacific +852 2230 3308 www.siemens.com/plm © 2014 Siemens Product Lifecycle Management Software Inc. Siemens and the Siemens logo are registered trademarks of Siemens AG. D-Cubed, Femap, Fibersim, Geolus, GO PLM, I-deas, JT, NX, Parasolid, Quality Planning Environment, Solid Edge, Syncrofit, Teamcenter and Tecnomatix are trademarks or registered trademarks of Siemens Product Lifecycle Management Software Inc. or its subsidiaries in the United States and in other countries. All other logos, trademarks, registered trademarks or service marks belong to their respective holders. Z11 30806 4/14 B