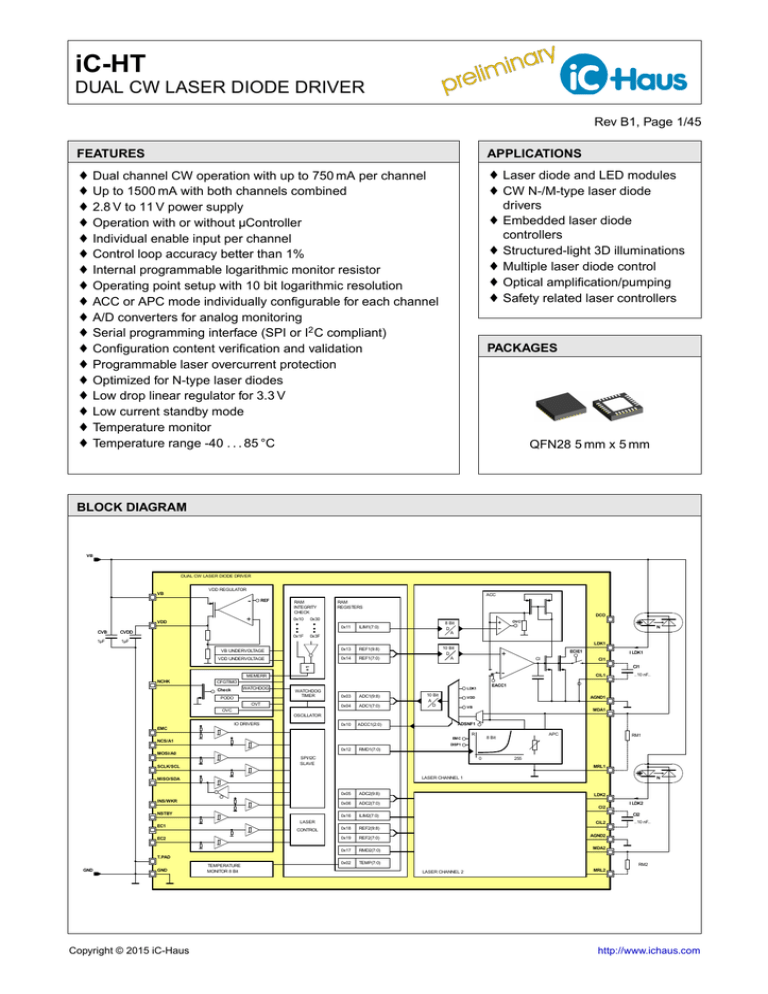

iC-HT Datasheet - iC-Haus

advertisement