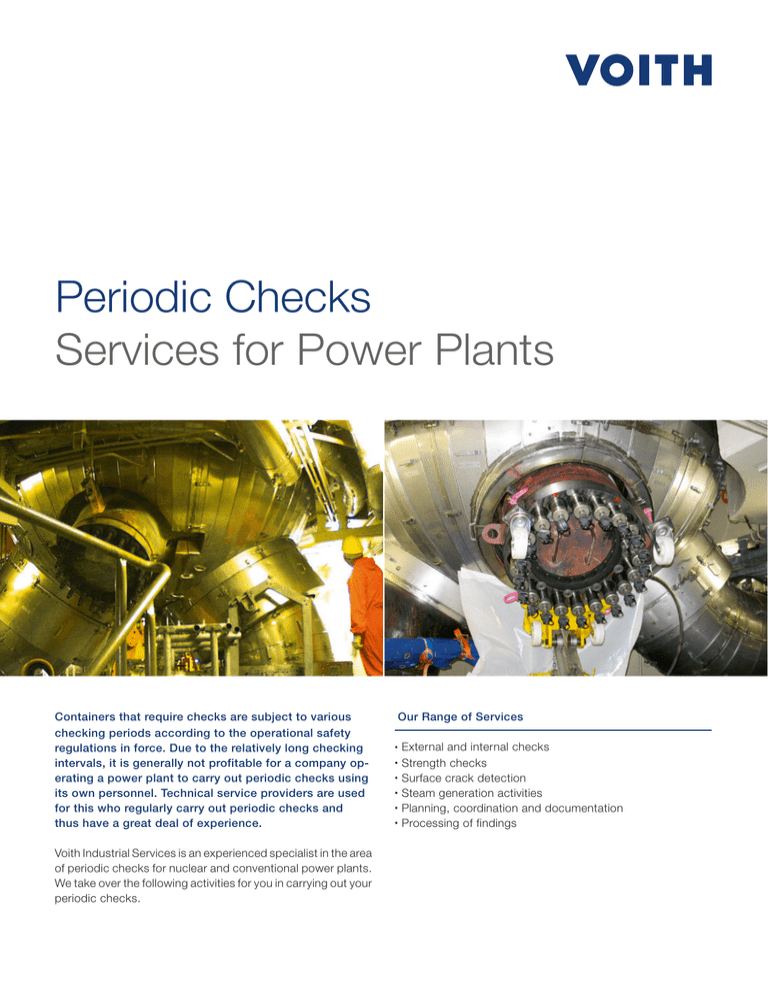

Periodic Checks Services for Power Plants

advertisement

Periodic Checks Services for Power Plants Containers that require checks are subject to various checking periods according to the operational safety regulations in force. Due to the relatively long checking intervals, it is generally not profitable for a company operating a power plant to carry out periodic checks using its own personnel. Technical service providers are used for this who regularly carry out periodic checks and thus have a great deal of experience. Voith Industrial Services is an experienced specialist in the area of periodic checks for nuclear and conventional power plants. We take over the following activities for you in carrying out your periodic checks. Our Range of Services • • • • • • External and internal checks Strength checks Surface crack detection Steam generation activities Planning, coordination and documentation Processing of findings External and Internal Checks Planning, Coordination and documentation The external check includes: • Evaluating the external condition of system parts in pressure systems that are in need of monitoring • Checking the safety-related equipment (presence, condition and functionality) In order to adhere to the schedule of an inspection, a detailed timetable is drawn up in advance. Coordination of documents relevant to comissioning is of enormous importance. Without the documentation being finally concluded, a system cannot be put back into operation. Our services here include: • Drawing up planning lists (on the basis of checking dates and work clearance lists) • Coordination of all sub-sections • Pressure check release • Carrying out checks after clearance • Documentation of checks with the applicable technical inspection body The internal check includes: • Checking the pressurized cladding • Checking compliance of the set-up with the specifications in the checking documents • Opening, cleaning and closing of containers and pressure anks • Execution together with the applicable technical inspection body Strength Checks Processing of Findings The condition of pressure systems in need of monitoring is checked before comissioning and periodically checked during the operating phase. Strength checks are usually static pressure checks for demonstrating the appropriate safety as compared to the permissible operating pressure. The strength check includes the following steps: • Water samples in the case of non-radioactive systems • Production of pressure sample connection for the area that is pressurized • Coordination and execution with the applicable technical inspection body • Documentation Application of checking procedures (VT, PT, FEP, among others) in an inspection can show findings that should be promptly repaired so as not to endanger the course of an inspection. In doing so, provision of tools is important. Voith provides the following services: • Elimination of findings after coordination with the operating company • On-site measurement • Carrying out visual checks Surface Crack Detection Surface crack detections evaluate the quality of manufacturing and repair of welding seams and the reproducibility of periodic checks at operationally stressed welding seams. The following steps are to be carried out: • Visual check before the non-destructive check • Preparation, coordination and execution with the applicable technical inspection body • Cleaning of the checkpoints • Documentation • Production of final condition through conservation Voith Industrial Services GmbH & Co. KG An der Hofweide 7 67346 Speyer, Germany Tel. +49 6232 6768-0 Fax +49 6232 6768-199 Energy-Services@voith.com www.voith.com/EnPC-Energy Contact Tel. Sales +49 6232 6768-101 Tel. Headquaters +49 6232 6768-0 Email Energy-Services@voith.com