Allowable CT Secondeary Lead Lenghts for Automatic Power

advertisement

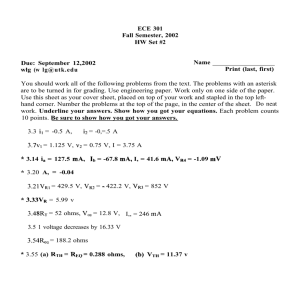

Allowable CT Secondary Lead Lengths for Automatic Capacitor Bank and Harmonic Filter Bank Controllers Introduction Current Transformers utilized with automatic capacitor banks and harmonic filter banks need to be placed within a limited range of the capacitor bank’s control system for proper and accurate operation. This technote provides a basis for determining the allowable CT secondary conductor length for ANSI metering class and relay class current transformers. The tables and figures provided in this technote assume the following: • The CT metering and relay class are based on ANSI C57.13 – ANSI/IEEE Standard Requirements for Instrument Transformers • A typical control system burden of 0.1 ohms. This is typical of systems provided by Northeast Power Systems, Inc. • Current transformer secondary conductors are Copper. Table 1 – Resistance and Reactance for CT Secondary Conductors Copper Conductor Size Resistance (Ohms/1,000 Feet) Reactance (Ohms/1,000 Feet) #6 #8 #10 #12 #14 0.98 1.56 2.4 4.0 6.2 0.102 0.104 0.100 0.108 0.116 Definitions Burden: That property of the circuit connected to the secondary winding of the current transformer that determines its active and reactive power requirement. The burden is normally expressed either as total ohms impedance with the effective resistance and reactance components, or as the total volt-amperes and power factor at the specified value of current or voltage, and frequency. Ratio Correction Factor (RCF): Is defined as the factor by which the marked ratio must be multiplied in order to obtain the true ratio. Transformer Correction Factor (TCF): Is defined as the factor by which a wattmeter reading or similar device must be multiplied to correct for the effect of instrument transformer RCF and phase-angle error. Metering Class Current Transformers Current transformers manufactured and rated in accordance with ANSI C57.13 are rated and name plated with a Metering Accuracy Classification and Standard Burden. Standard Burdens per the ANSI standard include the following: B-0.1, B-0.2, B-0.5, B-0.9, B-1.8. The burden value is the allowable maximum secondary impedance value in ohms for which the CT accuracy classification is based on. The accuracy classification for metering is based on the requirement that the current transformer correction factor is within specified limits when the power factor of the metered load has any value from 0.6 to 1.0 at the CT rated primary current. ANSI has three standard classifications, 0.3, 0.6, and 1.2. The accuracy classifications are based on the current transformers ratio correction factor (RCF) and transformer correction factor (TCF). In the most simplistic terms, the accuracy classification can be thought of as the percent error of the CT at a specific burden. For power factor correction, the lowest accuracy classification of 1.2% is adequate. Table 2 below provides the allowable CT conductor lengths for various standard burden ratings. As an example, a 600/5 current transformer with an accuracy rating of 1.2% and a burden rating of B-0.5 could be placed as far as 507’ away from the power factor control system when a #6 Copper conductor is utilized. Table 2 – Allowable CT Secondary Conductor Lengths for Various Sized Copper Conductors (in feet) Burden Rating Wire Gauge #6 #8 #10 #12 #14 B-0.1 101 64 41 24 15 B-0.2 203 128 83 50 32 B-0.5 507 320 208 124 80 B-0.9 913 576 374 224 144 B-1.8 1826 1153 749 449 289 Note: Above values based on a control system with a burden of 0.1 ohms. When lower accuracy ratings are acceptable, the allowable CT secondary conductor length can be considerably greater. Using the example above, the 600/5 current transformer could be placed as far as 1800 conductor feet away from the power factor controller and still have accuracy near 2%. The calculation of CT accuracy outside of the highest ANSI metering class accuracy rating of 1.2% is accomplished utilizing the current transformer secondary saturation curves as published by the CT manufacturer. The procedure for doing these calculations are as presented below for ANSI relay class current transformers. Relay Class Current Transformers ANSI C57.13 has standardized on the accuracy classes and the conditions under which the standard accuracy of relay class current transformers apply. These ratings are on the basis of the standard secondary terminal voltage a transformer will deliver at 20 times rated secondary amperes without exceeding 10 percent ratio error. Thus, a transformer classified with a C100 or T200 will deliver 200 volts at 20 times rated secondary current without exceeding 10 percent ratio error. Standard secondary voltage ratings include: 10, 20, 50, 100, 200, 400, and 800. These correspond to standard relay burden ratings of 0.1, 0.2, 0.5, 1.0, 2.0, 4.0, and 8.0 respectively. The ratio error must not exceed 10 percent at any current from 1 to 20 times rated current at any lesser burden ohms. To determine the ratio accuracy of a Relay Class Current Transformer for a specific application, the following are required: • The secondary excitation curve for the current transformer as shown in Figure 1 below. These curves are normally provided by the CT manufacturer. • The current transformer’s secondary winding resistance. This value is normally provided by the CT manufacturer. • The total secondary burden impedance of the control system and secondary conductors. Normally the burden impedance of a typical NEPSI control system can be taken as 0.1 ohms. By way of example, this technote will calculate in four easy steps the ratio error associated with a 600/5 current transformer having a saturation curve as shown in Figure 1. The distance between the power factor control system and the current transformer is 792 conductor feet. The design calls for a #10 Copper conductor. 1. Calculate the total secondary burden impedance: The total secondary burden impedance of the current transformer consists of the conductor impedance, CT secondary winding resistance, and the control and protection system impedance. The CT winding resistance from Figure 1 is 0.116 ohms. The control and protection system has an impedance is 0.1 ohms. The conductor impedance from table 1 is 2.4 ohms/1000’ X 743’=1.78 ohms. The total secondary impedance is equal to the control and protection system impedance, CT secondary winding resistance, and the conductor impedance (0.1 ohms + 1.78 ohms, 0.116 ohms = 1.996 ohms). 2. Calculate the CT Secondary Excitation Voltage: The CT secondary excitation voltage is calculated by multiplying the total secondary burden impedance by the nominal CT secondary current of 5 Amps. (5 amps x 2.0 Ohms = 10 Volts). 3. Obtain the Secondary Excitation Current: From Figure 1, the excitation current with 10 volts of excitation voltage for the 600/5 CT is 0.1 amps. 4. Calculate the turns ratio error: The turns ratio error is calculated by multiplying the ratio of the exciting current, 0.1 amps, to the assumed secondary current of 5 amps by 100. The error for this example was calculated to be 2%. This error would be considered acceptable. Figure 1 – Typical CT Secondary Excitation Curve. The Excitation Current Associated with a 600/5 Current Transformer Operating with a Secondary Voltage of 10 Volts is 0.1 Amps. Conclusion This technote provided a basis for determining the allowable CT secondary conductor length for ANSI metering class and relay class current transformers. This technote focused on current transformers dedicated for the power factor correction control system. When a CT is to supply, or be shared with multiple devices, the burden impedance of all connected devices must be considered. In addition, proper operation of secondary connected devises for the full operating range of the CT must be considered. For example, CT’s used for relaying should remain accurate through the maximum expected secondary current during faults. Northeast Power Systems, Inc. 66 Carey Road Queensbury, New York 12804 Phone: 518-792-4776 Fax: 518-792-5767 E-mail: sales@nepsi.com Website: www.nepsi.com Copyright © 1999 - 2012 Northeast Power Systems, Inc.