Using Performance Standards to Specify Exterior Side

advertisement

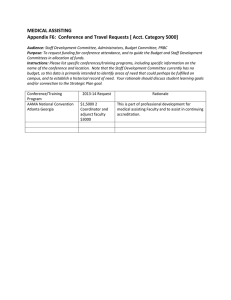

1 Using Performance St d d tto S Standards Specify if Exterior Side-Hinged g Doors 2 The American Architectural Manufacturers Association (AAMA) is a Registered Provider with The American Institute of Architects Continuing Education Systems. Credit earned on completion of this program will be reported to CES Records for AIA members. Certificates of Completion for non-AIA non AIA members are available on request request. This program is registered with the AIA/CES for continuing professional education. As such, it does not include content that may be deemed or construed to be an approval or endorsement by the AIA of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product. Questions related to specific materials, methods, and services will be addressed at the conclusion of this presentation. presentation 3 Copyright Materials This presentation is protected by U.S. and International copyright laws. Reproduction, distribution, display and use of the presentation without written permission of the speaker is prohibited. © American Architectural Manufacturers Association 2008 Using Performance Standards to Specify Exterior Side-Hinged Doors L Learning i Objectives: Obj ti Fenestration Standards and Code References Use The Standard To Specify Product Type, Performance Level and Key Performance Attributes Analyze Special Requirements for Door Types Examine Materials and Glazing g Requirements q Learn To Use the Short Form Specification 4 5 AAMA/WDMA/CSA 101/I.S. 2/A440-05 6 Getting to 101-05 101 05 1947 The first Guide Specification for Aluminum Windows was released released. 1985 AAMA “101” standard for aluminum windows and doors was released released. 1988 AAMA “101” standard for aluminum windows and doors is updated from 1985 document and released. 1950 Performance levels for different applications were first defined. 1962 AAMA 302 aluminum window standard was released. 1993 AAMA “101” standards for aluminum and vinyl windows and doors combined and released. 1986 AAMA “101” standard for vinyl windows and doors was released. 1994 AAMA and NWWDA begin work to consolidate the two major U.S. standards for windows and glass doors. 1997 ANSI/AAMA/NWWDA 101/I.S. 2-97 was released, encompassing products made of aluminum, vinyl, fiberglass or wood, as well as those with aluminum- or vinyl-clad wood framing members. 2002 ANSI/AAMA/WDMA 101/I 101/I.S. S 2/NAFS - 02, 02 was released, released which incorporates skylights, sidelites and transoms for the first time. 2005 AAMA/WDMA/CSA 101/I.S. 2/A440-05 was issued, fully consolidating U.S. and Canadian standards and adding four more operator types, eight additional materials and requirements for side-hinged doors. 7 Key y Features of AAMA/WDMA/CSA 101/I S 2/A440–05 101/I.S. 2/A440 05 Performance Based 8 Key y Features of AAMA/WDMA/CSA 101/I S 2/A440–05 101/I.S. 2/A440 05 Performance Based Material Neutral 9 Key y Features of AAMA/WDMA/CSA 101/I S 2/A440–05 101/I.S. 2/A440 05 Performance Based Material Neutral Required by IBC and IRC (An alternative to the IBC & IRC requirements is the ASTM E 330.) 10 Key y Features of AAMA/WDMA/CSA 101/I S 2/A440–05 101/I.S. 2/A440 05 Performance Based Material Neutral Required by IBC and IRC Multinational in Scope 11 Using 101/I.S. 101/I S 2/A440-05 What type of product? What application? Performance level? 12 What Type of Product? 13 Product Types 30 product types are identified in the 2005 Standard by Specific Letter Codes Codes. 14 Application: What Kind of Building? 15 Performance Class R LC C HC AW 16 Door Performance Grades Product Performance Class Minimum Performance Grade Minimum Design Pressure (Pa/psf) Wind Speed (mph) R 15 720 (15.0) 77 LC 25 1200 (25.0) 100 C 30 1440 (30.0) 109 HC 40 1920 (40.0) 126 AW 40 1920 (40.0) 126 17 Product Designation System SHD – LC 25 – 36 x 80 PRODUCT KEY A = Product (Operator) Type: Side‐Hinged Door (SHD) B = Performance Class: LC C = Performance Grade: Design Pressure = 25 psf D = Maximum Size Tested: Width x Height (36 x 80) 18 AAMA Label 19 Basic Performance Requirements Force to latch Resistance to air infiltration Resistance to water penetration Structural adequacy to withstand design wind loads Resistance to forced entry 20 Force to Latch 21 Force to Latch Test method based on ANSI/BHMA procedure Incorporates unique criteria for maximum closing force to accommodate: Strike latch load Resistance of the weatherstrip Resistance of the door sweep 22 ASCE Design Wind Load Map Map reprinted with permission of ASCE. 23 Design Wind Load Table (psf) Mean Roof Height (ft.) Positive Pressure All Areas Negative Pressure Area 4 Area 5 BASIC WIND SPEED – 70 MPH 15 16.6 -17.6 -22.6 20 18.0 -19.1 -24.6 25 19.2 -20.4 -26.2 30 20.3 -21.5 -27.7 40 21.9 -23.3 -29.9 50 23.4 -24.8 -31.9 60 24.6 -26.1 -33.6 70 25.7 -27.2 -35.0 80 26 7 26.7 -28 28.3 3 -36 36.4 4 90 27.7 -29.4 -37.8 Excerpt from ASCE-7 24 Performance Considerations Related to Design Pressure Performance Grade = Design Pressure Structural Test Pressure = 1.5 x Design Pressure Water Resistance Test Pressure = 0.15 x Design Pressure for R, LC, C and HC 0.20 x Design Pressure for AW 25 Air Leakage Air Infiltration Control Panel 26 Air Leakage Test Pressure FOR VARIOUS PERFORMANCE CLASSES 7 6.2 6.2 6 5 4 3 2 1.6 1.6 1.6 psf p 1 0 R LC C HC AW 27 Maximum Air Leakage FOR VARIOUS PERFORMANCE CLASSES AND GRADES Field air infiltration is permitted to be 1 1.5 5 times values shown below below. 0.35 cfm/sq. q ft. 0.3 0.25 0.1 cfm/sq. ft for all ft. compression seal products 02 0.2 0.15 01 0.1 0.05 0 R LC C HC AW 28 Water Penetration 29 Water Test Pressure FOR VARIOUS PRODUCT CLASSES AND GRADES Recommended 12 psf Maximum Optional Water Test Pressure, 15 psf in Canada. 30 Why a Water Test Pressure Cap? A water test pressure of 12 psf corresponds to a Design Pressure of 80 psf, which equates to a sustained wind velocity of 177 mph The test water spray equates to rainfall at 8 inches per hour, which has never been recorded in U.S. history 31 Limited Water (LW) Performance f Side-Hinged for Sid Hi d Doors D Due p primarily y to accessibility/egress y g demands,, allowance is made for SHD to be tested to less than the minimum Water Resistance Test Pressure. Pressure If this option is chosen chosen, SHD is listed and labeled “LW” with the test pressure that was achieved. a pe S SHD-R20-LW10 0 0 Example: 32 Minimum Performance R Requirements i t Listed Li t d by b Class Cl Door Classes Water Design Structural Resistance Pressure Test Pressure Test Pressure (psf) (psf) (psf) Required Percentage For Water Testing R 15 22.5 2.9 * LC 25 37.5 3.8 15% C 30 45.0 4.5 15% HC 40 60.0 6.0 15% AW 40 60.0 8.0 20% * R15 products are tested at 2.9 psf, which is higher than the 15% of design pressure, as required for other higher ratings within the R class. 33 Structural Loading 34 Uniform U if L Load d Deflection D fl ti Test at the Design Pressure A minimum uniform design pressure load is applied to the test specimen specimen, first to the exterior surface (positive) and then to the interior surface (negative) Deflection at design g pressure is reported for all products. For HC and AW products, the deflection must not exceed d L/175 35 Minimum Structural Performance Requirements by Class Door Classes Design Pressure (psf) Structural Test Pressure (psf) R 15 22 5 22.5 LC 25 37.5 C 30 45.0 HC 40 60.0 AW 40 60.0 36 Structural Load Requirements Uniform Load Structural Test (150% of Performance Grade) There can be no permanent deformation of any mainframe, leaf or threshold/sill in excess of 0.4% of its span for R, LC class products, 0.3% of its span for f C and d HC class l products, d t or 0 0.2% 2% off itits span for AW class products 0.4%, 0.3% or 0.2% 37 Resistance to Forced Entry ASTM F 842 – Sliding Doors AAMA 1304 – Side-Hinged Doors 38 AAMA Label 39 Side-Hinged Side Hinged Door Testing 40 Minimum Test Size Requirements T t Sample Test S l Requirements R i t Side-Hinged Door 2005 Minimum Designation Frame Size SHD-R15 900 mm (36”) x 2000 mm (79”) SHD-LC25 900 mm (36”) x 2100 mm (83”) SHD-C30 1000 mm (40”) x 2100 mm (83”) SHD-HC40 1000 mm (40”) x 2100 mm (83”) SHD-AW40 1200 mm (48”) x 2400 mm (95”) 41 Minimum Test Sizes Largest Width Must include all intermediate members to be qualified. Largest g Height 42 Maximum Size Tested 43 Higher Performance G d ? Grades? 44 Optional Performance Grades Optional Applicable Performance Product g Grade Designation Design Pressure Structural Test Pressure Water Resistance Test Pressure R, LC, C and HC AW psf (Pa) psf (Pa) psf (Pa) psf (Pa) 20 R 20.0 (960) 30.0 (1440) 3.00 (150) - - 25 R 25.0 (1200) 37.5 (1800) 3.75 (180) - - 30 R,LC 30.0 (1440) 45.0 (2160) 4.50 (220) - - 35 R,LC,C 35.0 (1680) 52.5 (2520) 5.25 (260) - - 40 R LC C R,LC,C 40 0 40.0 (1920) 60 0 60.0 (2880) 6 00 6.00 (290) 45.0 (2160) 67.5 (3240) 6.75 (330) 9.00 (440) 50.0 (2400) 75.0 (3600) 7.50 (360) 10.00 (480) 55.0 (2640) 82.5 (3960) 8.25 (400) 11.00 (530) 60.0 (2880) 90.0 (4320) 9.00 (440) 12.00 (580) 45 50 55 60 R,LC,C, HC,AW R,LC,C, HC AW HC,AW R,LC,C, HC,AW R,LC,C, HC,AW Optional Performance Grades higher than those shown on the table may be used in increments of 5 psf. Water resistance test pressures are capped at 15 psf in the 2002 version of the standard. Ratings are capped at the entry level plus 60 psf in the 2002 & 2005 version of the standard, except for the AW class. 45 Optional Performance Grades (cont'd) Optional Applicable Performance Product g Grade Designation Design Pressure Structural Test Pressure Water Resistance Test Pressure R, LC, C and HC AW psf Pa psf Pa psf Pa psf Pa 65.0 3120 97.5 4680 9.75 470 12.00 580 R,LC,C, HC,AW R,LC,C, HC AW HC,AW R,LC,C, HC,AW LC,C, HC,AW LC C LC,C, HC,AW 70.0 3360 105.0 5040 10.50 510 12.00 580 75.0 3600 112.5 5400 11.25 540 12.00 580 80.0 3840 120.0 5760 12.00 580 12.00 580 85.0 4080 127.5 6120 12.00 580 12.00 580 90 C, HC,AW 90.0 4320 135.0 6480 12.00 580 12.00 580 95 HC,AW 95.0 4560 142.5 6840 12.00 580 12.00 580 100 HC,AW 100.0 4800 150.0 7200 12.00 580 12.00 580 65 70 75 80 85 Optional Performance Grades higher than those shown on the table may be used in increments of 5 psf. Water resistance test pressures are capped at 15 psf in the 2002 version of the standard. Ratings are capped at the entry level plus 60 psf in the 2002 & 2005 version of the standard, except for the AW class. 46 Optional O ti l Performance Grades Must meet ALL minimum gateway t performance f requirements before testing at optional higher grades. 47 Supplemental Requirements for Sid Hi Side-Hinged d Doors? D ? 48 Additional Side-Hinged D Door R Requirements i t Operating O i Cycle C l Performance P f (AAMA 920) Vertical Loading Resistance (AAMA 925) Mulled Assemblies (AAMA 450) 49 Operating Cycle Performance 50 Operating Cycle P f Performance Performance Class Number of Cycles R 25 000 25,000 LC 100,000 C 250,000 HC (except architectural terrace doors) 500,000 AW (except architectural terrace doors) 1 000 000 1,000,000 AW (architectural terrace doors) 25,000 51 Vertical Loading Resistance 52 Vertical Loading Resistance Rating g Applied pp Load R LC R, 675 N (150 lbf) C, HC 1115 N (250 lbf) AW 2230 (500 lbf) 53 Mulled Assemblies 54 Mullions or Other Structural Members Products assembled at the factory are tested as a single complete unit per the 2005 standard or its predecessors Products stacked or combined in the field must be tested for mullion integrity per AAMA 450 55 Mullions and Other Structural Members Must withstand the full design load for the project site Deflection for all AW and HC products cannot exceed 1/175 of the span length in the 2005 version Evidence of compliance may be by structural analysis by a Professional Engineer or by AAMA 450 56 Materials Requirements 57 Framing Material Requirements PVC extrusions, where used as a structural member, must comply with AAMA 303 Wood parts Must be kiln kiln-dried dried to a moisture content no greater than 12% Surface Su ace must ust be suitable su tab e for o a an opaque finish 58 Framing Material Requirements Other materials Cellular PVC, Fiberglass, Steel, Cellulosic Composites Composites, Fiber Reinforced PVC & ABS Plastic were added to the 2002 standard References to other polymers were included in the 2005 standard 59 Glass & Glazing Materials Safety glazing materials must conform to ANSI Z97.1 or CPSC 16 CFR 1201 Tempered glass must conform to ASTM C 1048 (Kind FT) (Glass doors must have safety glazing) Sealed insulating glass must conform to ASTM E 774 Level A or E2190 60 Glass and Glazing Materials ASTM E 1300-07e1 1300 07e1 “Standard Standard Practice For Determining Load Resistance of Glass in Buildings” Buildings Glass furnished by the manufacturer must meet the values g given in ASTM E 1300 for the design pressure rating of the product 61 Short Form Specification All (doors) shall conform to the ________ voluntary specification(s) in AAMA/WDMA/CSA 101/I.S. 101/I S 2/A440-05, 2/A440 05 be labeled with the AAMA, CSA or WDMA label have the sash arrangement(s) label, arrangement(s), leaf arrangement(s), or sliding door panel arrangement(s) and be of the size(s) shown on the drawings and be as manufactured by ________ or approved equal. 62 Short Form Specification All (doors) shall conform to the SHD-LC25 voluntary specification(s) in AAMA/WDMA/CSA 101/I.S. 101/I S 2/A440-05, 2/A440 05 be labeled with the AAMA, CSA or WDMA label have the sash arrangement(s) label, arrangement(s), leaf arrangement(s), or sliding door panel arrangement(s) and be of the size(s) shown on the drawings and be as manufactured by XYZ Doors or approved equal. 63 AAMA/WDMA/CSA 101/I.S. 2/A440-05 64 Door-Related Changes 2008 vs. 2005 Performance Classifications – Reduced from 5 to 4 – Elimination of C and HC – Addition of CW Performance P f G Grade d Caps C – Increased to 100 psf for R and LC products Operation/Cycling O ti /C li – AW (except ATD) reduced to 500,000 – Cycle C l rate t off 12 tto 24 cpm (R class l products) d t ) 65 Door-Related Changes 2005 vs. 2008 Force to Latch – Test and record only Glazing Exception – Heaviest glazing must be tested C Clarification a cat o o of tthe e Design es g Pressure essu e ((DP)) a and d Performance Grade (PG) Revision of Primary Designators for DP, PG and size tested Prescriptive Requirements Identified for Use of Secondary Designator 66 Using Performance St d d tto S Standards Specify if Exterior Side-Hinged g Doors 67 Seminar Evaluation Please take a moment to complete p the evaluation form. Thank You.