Error introduced by the disturbance of the local temperature using

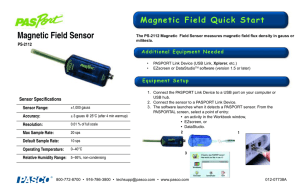

advertisement

Error introduced by the disturbance of the local temperature p using g thermocouples p Heat flux and thin film temperature sensor B. Garnier Lab. Thermocinétique (LTN) UMR CNRS6607 ‐ Polytech’Nantes Advanced Spring School Thermal Measurements&Inverse Techniques - 6th Edition – Domaine de Françon Biarritz, France March 1-6, 2015 Lecture L2 part2/3 / 1 B. Garnier LTN/Polytech’Nantes Outline 1. Error introduced byy the disturbance off the local temperature p usingg thermocouples p - Surface temperature measurement or within a volume - Error E analysis l i andd model d l -Practical consequence and examples - Semi intrinsic thermocouple 2. Heat flux measurement (direct and inverse methods) 3. Thin or thick film temperature sensor 2 Error introduced by the disturbance of the local temperature using thermocouple • Whatever the selected temperature measurement method, one have parasitic effects • Two type of errors : thermometric phenomenon phenomenon + used device for its meas. interaction between sensor, sensor medium and environment which involves a local disturbance of the temperature field. ? 3 Illustration‐ Tutorial T4‐ 4mm 60°C 5mm 5 5 5 1 2 3 7 4 5 6 19,8°C 20°C Fig.1 : instrumented PMMA sample with 0.2mm dia. type K thermocouple *, mm 5 10 15 # 1 2 3 T , °C 49 9 49,9 40,5 31,5 # 4 5 6 T , °C 43 5 43,5 35,4 27,7 # T , °C 7 34,8 Table 3 : steady state temperature measurements T7 - T2 = 5.7°C ! and ΔT = 5.7/(60-20)=14 % Rq: If we use inox sheathed thermocouple‐> it will be larger ! 4 Error analysis and model - Surface temperature measurement Radiation Sensor Bardon 1999, Cassagne 1980 & 1986 Radiation Conduction Radiation Tp: wall temp. Tc: sensor temp. convection Measurement T(t) For an opaque medium: 3 effects •Macroconstriction •Thermal contact resistance •Fin Measurement error : (t) = T(t) - Tc (t) Tp(t) (t) Tc(t) TE 5 -Temperature measurement within a volume Conduction Convection + radiation Radiation dV Measurement Same 3 effects: •Macroconstriction •Thermal contact resistance •Fin Measurement error : (t) = T(t) - Tc (t) 6 - Error model • Steady state surface temperature measurement of an opaque medium 10 yE adiab. TE hE T hE hc hr TE x ,c 2yE hc T f hr To F hE : thermal conductivity a) Macroconstriction effect : T ‐ Tp = rM with 1 rM 4 yE for a disc of radius yE 96% of the T - Tp temperature drop is within an hemisphere of center 0 and radius 10 yE 7 ) Error model b) The contact resistance effect Tp - Tc = rc rc=Rc /S Rc (m ( 2 K W K W‐11 ) c) The fin effect: Tc - TE = rE Measurement error thermocouple assumed as a rod of radius yE rE 1 /( y E 2hE E y E ) =T – Tc ? T - Tp = rM Tp - Tc = rc Tc - TE = rE =T T – Tc=K K (T - TE) T - Tc = (r ( M +rc ) with ih T TE rM rc rE 1 K rE 1 rc rM 8 =T – Tc=K (T - TE) with K 1 rE 1 rc rM Discussion: small if: •T- TE small •K small rE >> rc + rM rM 1 4 yE high thermal conductivity medium rM << rc low thermal conductivity medium rM >> rc 9 Transient surface temperature measurement and K (t) = K(t) [T(t) – TE ] K(0) K() K(0) ? T t<0 0 •If rc 0, K(0)=1, the error is about 100% at t=0 •If rc =0 (perfect contact), contact) the initial error is smaller: t TE b bE TC T TC bE TC TE b (0) T TC t 0 b= c (0) T TC bE (T TE ) b bE bE EbE E bE [(TC T ) (T TE )] b K ( 0) effusivities bE 1 b bE 10 Temperature measurement within a volume h T 2y Temperature measurement p with a cylindrical sensor inside the medium Tc • Same error model but with : • rc= Rc/S 2 Log rM 2 y 1 S 2 y y 11 2.4.3. Practical consequence and examples, semi intrinsic thermocouples • Practical consequences : 1. even for perfect contact rc = 0 there is an error which depends on the ratio rM /rE. 2. For high thermal conductivity material, rM << rc Thus, one must take care that rc is small ll andd remains i stable. t bl The Th contact t t pressure will ill have h to t be b high hi h andd constant, t t surface will have to be plane without waviness, the interstitial medium with the highest possible thermal conductivity (welding, grease…). In addition, one should avoid oxide films as well as mechanical shocks and vibrations which can modify considerably rc and consequently the measurement error. 3. For low thermal conductivity material , rM >>> rc. One can reduce macroconstriction effect by increasing the radius of the sensitive element without increasing the section of the connections A contact disc of high thermal conductivity material will be used. y D E 12 4. Whatever the type of measurement, the fin thermal resistance rE should be as high as possible. The transversal area, the conductivity, the heat transfer coefficient have to be chosen the smallest possible. One also should have low emissivity surface, connection protected from high temperature fluids movements or radiation, TE being modified in those situations. 5. Finally, the error is all the more small as TE should be as close as possible to the temperature T to measure . At the price of a technological complication, one can add an external heat source on the connection so that its temperature p TE is controlled in order to stay a close as possible as T “compensated heat flux sensors”. However for correct measurement, the thermal resistance rE should stay high in order to prevent the compensation heating from disturbing the temperature field in the medium. 13 with contact disc • Application -for steady state temperature measurement using a thermocouple with and without a contact disc thermocouple unique rod with a radius yB = 0.5 mm, an infinite length, B = 15 W.m-1.K-1 and hB = 5 W.m-2K-1. rE ? rE = rB rE rB + rB without ith t contact t t disc, di 1 4 y B D with contact disc hB D 1 y B 2hB y B B yB B contact disc 14 Tab 1. Effect of the thermal conductivities of the medium and of the disc on rM, rc, rE and K rM (K.W-1) Rc (K.W-1m2) rc(K.W-11) rE (K.W-1) K Low thermal conductivity =10-1 W.m-1.K-1 without ith t disc di with ith disc di 5000 250 10-3 10-3 1270 3,18 1700 1733 0.786 0.127 hB D yB High thermal conductivity =100 W.m-1.K-1 without ith t disc di with ith disc di 5 0.25 10-4 10-4 125 0.31 1700 1733 0.072 0.0003 =T – Tc=K (T - TE) with ih B K contact disc 1 rE 1 rc rM 15 • Temperature measurement with semi intrinsic thermocouple Medium M itself (presumately electrically conducting) is used as one wire of the thermocouple it it has only one connection wire instead of two, thus rE is twice larger the measured temperature T is intermediate between Tp and Tc T Tp T Tp A T M eA M M Tc i M A Tc TE 16 i T - T K i ( T TE ) Semi intrinsic thermocouple Tp T p T A T Tc M Semi intrinsic T i T Ki Traditionnal thermoc. A rM rc A M Tc TE rM rc rE rM rc K rM rc rE Ki < K • Error is considerably lower than with a traditional thermocouple (2 to 5 times) but the calibration of the semi intrinsic thermocouple is almost always required. 17 Conclusion for the errors due to thermal disturbance Error model and recommandations for correct implementation of thermocouples = ( rM , rc rE , T-TE ) Thermocouples should be implemented along isothermal lines ( 100 ) 100 Thermocouples disturbance hemisphere of radius 10 (/2) 20 Thermocouples should not be too close 18 Heat flux measurement: direct and inverse methods -Heat flux sensor HFS with gradient Principles : measurement of the temperature difference or by covering the medium with a polymer film with thin film sensors Tangential Normal V T2 T1 V wall A B A B wall It works whatever the heat flux direction with steady state or for slowly variable temperature. Normal gradient HFS Omega : 8 to 10 % ‐Khaled 2009‐ Rq: it can be more …. Omega Rdf Captec Vatell Hukseflux Wuntronic 19 -Inertia heat flux sensor and heat flux sensor with electric dissipation (zero method) P=UI wall wall T(t) Inertia heat flux sensor works for heat flux coming from the environment T T=0 0 T heat flux sensor with electric dissipation works only for heat flux leaving the wall and for steady state or slowly variable temperature temperature. 20 -Enthalpic heat flux sensor Tp TF wall T=0 TE-S It works for heat flux coming from the surrounding 21 Heat flux sensor with indirect measurement Inverse method ! thermocouple (50m 50m ) • With wire thermocouple ( P t t JP Bardon Patent B d 1994 3 thermocouples t) ? T1 T2 T3 6 mm IHCP t) ? 5 mm 2 thermocouples Heat flux sensor with thermocouples (type K 50m) (F Bouloc, (F. B l B. B Bourouga B 2007) Exhaust pipe 5% ( th. type K 50m) B Azerou et al. 2013 t) ? Hot junctions • criteria for correct locations of thermocouples Tutorial T4 22 m m m m 5 6 •With thin film heat flux sensor (HFS) HFS with wire th. 30 µm r1 r2 R(T) 20 mm • Much accurate locations of the sensors (2 to 3 m) • Easier HFS mass production HFS mass production 23 • Comparison wire thermocoples and thin film heat flux sensors • Measured temperature 28 TR1 TR2 TR3 TR4 26 Température ((°C) HFS with wire thermocouples(TH) HFS with thin film sensors (TR) ((copper pp RTD)) 24 22 20 18 Heat exchanger 0 25 50 75 100 125 150 175 200 Temps (s) • Measured heat flux (function specification Beck 1985) HFS with wire thermocouples Thermocouples HFS with thin film RTD Heater copper etched foil Azerou B. et al. , J. Phys. CS 2012 elec Results • Comparaison with elec (heating device): HFS with wire thermocouples : 5,3% / elec HFS with thin films : 2,2% / elec • Same time constant tr ( 0,3 to 1% ; tr 175 s) • HFS with thin film: easy mass production 24 Thin or thick film temperature sensor The smallest wire thermocouple has a of 12 m (Lab FEMTO 5m) How to make them smaller ? (less ( invasive)) Thin film ( thick.100 nm) or thick ( ) films (thick.a few m) ( ) • Temperature measurement bias • Time constant ‐> s but Need surface with high quality (low surface roughness) Sensitivity V/°C ou /°C ‐> calibration is required TTake k care about connections : b i columnar structure Table1 : F.e.m F e m constantan (0,4 (0 4 Ni 0,6 0 6 Cu) evaporated on quartz in vacuum Thickness (nm) Elaboration F.e.m. at 20°C (V/K) 40 evaporated ‐30 100 evaporated ‐34 250 evaporated ‐38 ‐‐> bulk ‐42 25 How to realize thin or thick film temperature sensors ? 30m Thin film deposition film deposition (PVD,CVD…) (PVD CVD ) (a) borosilicate 150m PDMS x (b) Thick 85nm gold 2D heat flux sensor Hamadi et al. 2010 et al. 2010 Electrolytic or galvanic or galvanic deposition 1D heat flux sensor Azerou et al. 2012 Thick 9m copper + tin Serigraphy 26 Glass temperature measurement during grinding Spray! Sintered diamond composite with g tungsten Thermocouple junctions 40 9 layers Fi Figure 46 46 : Vue de dessous de la plaque du verre (Nickel pulvérisé). V d d d l l d (Ni k l l é i é) 6 layerss 25 20 Thickness of 4 to 12 m Take care about increased oxydation 15 9 layers 10 An annealing process at 400°C might be necessary to stabilize to stabilize electrical prop. prop 5 0 Nickel Glass l 30 Voltage ((mV) Figure 45 : Vue de dessus de la plaque du verre (Cuivre pulvérisé). Copper Nickel Calibration 35 Copper 0 50 100 150 200 250 300 350 400 450 500 Temperature (°C) annealing=« recuit » 27 Thanks for your for your attention! Nantes 28