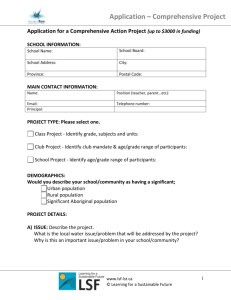

Circular duct SR SR

advertisement

lindab | safe Circular duct SR Dimensions 1 t l Ød 2 3 t l Ød* 4 5 6 Description Circular duct. 7 Ducts are always produced locally and can therefore have different thicknesses and other specifications per country. 8 The ducts can be produced both with and without click function (notches). Please specify when ordering. 9 10 11 12 13 14 15 16 Ordering example SR 17 18 Product Dimension Ød Length l Type 200 3000 CLIC Ød std nom 63 80 100 112 125 140 150 160 180 200 224 250 * 280 300 * 315 * 355 * 400 * 450 * 500 * 560 * 600 * 630 * 710 * 800 * 900 * 1000 * 1120 * 1250 * 1400 * 1500 * 1600 * O πd m 0,198 0,251 0,314 0,352 0,393 0,440 0,471 0,503 0,565 0,628 0,704 0,785 0,880 0,942 0,990 1,115 1,257 1,414 1,571 1,759 1,885 1,979 2,231 2,513 2,827 3,142 3,519 3,927 4,398 4,712 5,027 A πd²/4 m2 0,003 0,005 0,008 0,010 0,012 0,015 0,018 0,020 0,025 0,031 0,039 0,049 0,062 0,071 0,078 0,099 0,126 0,159 0,196 0,246 0,283 0,312 0,396 0,503 0,636 0,785 0,985 1,227 1,539 1,767 2,011 t std mm 0,5 0,45 0,45 0,5 0,45 0,5 0,5 0,5 0,5 0,5 0,6 0,5 0,55 0,55 0,55 0,55 0,55 0,7 0,7 0,8 0,7 0,7 0,8 0,8 0,9 0,9 0,9 0,9 1,25 1,25 1,25 * With outturned stiffening corrugation. 56 We reserve the right to make changes without prior notice l std mm 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 2400 2400 2400 ml std kg/m 0,89 0,91 1,14 1,42 1,41 1,76 1,89 2,02 2,26 2,56 3,42 3,18 3,92 4,20 4,41 4,96 6,01 8,60 9,54 12,2 13,1 12,0 15,5 17,4 21,7 24,1 27,0 30,2 48,0 51,4 54,8 lin dab | safe Circular duct SR Technical data 1 [Pa/m] 200 0 0 0 4 50 5 12 10 00 80 0 0 5 4 3 Δpt 63 40 0 ] 5 5 3 [mm 50 10 31 25 20 0 0 5 16 12 10 10 ød v[ m /s ] 50 80 20 15 63 2 100 2 1 6 0.5 7 0.1 8 0.05 0.02 5 10 10 50 50 100 100 500 500 1000 1000 5000 10000 5000 10000 q 9 50000 [l/s] 50000 100000 [m3/h] 10 11 12 13 14 15 16 17 18 We reserve the right to make changes without prior notice 57 lindab | safe Circular duct SR Technical data 1 2 3 4 5 Special versions Strength We can supply ducts with the following special designs: • In intermediate dimensions, see page 15. • Extra tight, with nitrile rubber seal in the lock seam • In other sheet metal thicknesses Positive pressure in case of high positive pressure, the seal moulding lips will first start to whistle. At considerably higher pressure, the joints between the ducts will be forced apart. If you manage to fix the connections very well, the ducts will burst at their seams at even higher pressure. The high pressures needed for this to happen are not relevant to ventilation installations. Extra tight, with seam seal When extremely good sealing is required in the spiral seam, the ducts can also be supplied with a special rubber seal in the seam. 7 Other sheet metal thicknesses If extra stability is needed in ducts, because of high negative pressure etc., they can be supplied with thicker sheet metal than standard. Remember that the thickness increase always reduces the inner diameter. Fittings for such special ducts must be specified separately and sometimes have to be made specially. 8 Reinforcement corrugations Ducts of Ø250 mm and above are normally given stiffening corrugations to increase radial stiffness. 6 Negative pressure In installations with high negative pressure, there is a risk that the ducts could collapse. This seal is very effective at stopping leakage of vegetable oils and greases, and most petroleum products including white spirit. This phenomenon is referred to as buckling, and can suddenly happen at the weakest point in the system. Buckling wanders along the duct, which can be completely flattened. The weakest point is frequently a "transport dent" on a duct. For this reason, only use undamaged ducts in systems which are close to the critical pressure! Sealing The ability of the seal moulding to seal is different from these pressures, and is noted on page 45. 9 10 11 12 Collapsing pressure Diameter Sheet metal thickness standard t 63 80 100 125 160 200 250 315 400 500 630 800 0,5 0,45 0,45 0,45 0,5 0,5 0,5 0,55 0,55 0,7 0,7 0,8 0,9 -1,0 -0,8 0 -10 14 0,9 With stiffening corrugations Without stiffening corrugations 13 1000 1250 -7,2 Negative pressure -4,3 -4,8 -3,0 -3,5 -3,0 -3,2 400 500 630 800 -11,7 -20 -17,0 -21,4 -30 15 -40 -40,4 * 16 -50 -47,0 * * Collapse not achieved 17 [kPa] -60 63 80 100 125 160 200 250 315 18 58 We reserve the right to make changes without prior notice 1000 1250