Membrane Replacement Procedures

advertisement

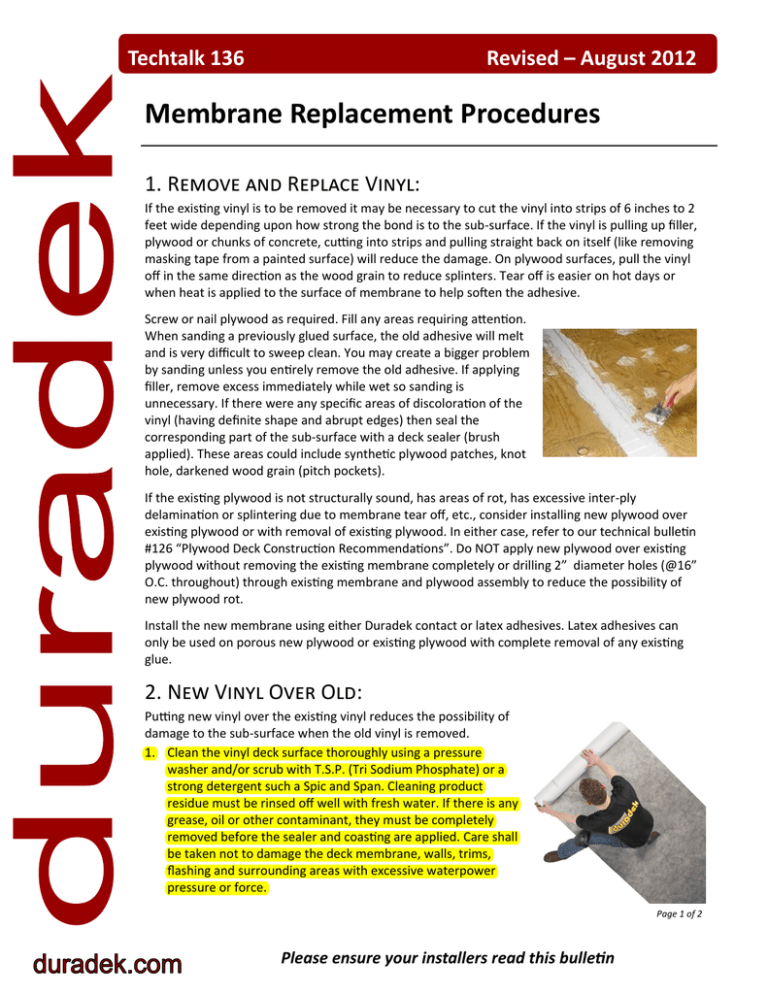

Techtalk 136 Revised – August 2012 Membrane Replacement Procedures 1. Remove and Replace Vinyl: If the existing vinyl is to be removed it may be necessary to cut the vinyl into strips of 6 inches to 2 feet wide depending upon how strong the bond is to the sub-surface. If the vinyl is pulling up filler, plywood or chunks of concrete, cutting into strips and pulling straight back on itself (like removing masking tape from a painted surface) will reduce the damage. On plywood surfaces, pull the vinyl off in the same direction as the wood grain to reduce splinters. Tear off is easier on hot days or when heat is applied to the surface of membrane to help soften the adhesive. Screw or nail plywood as required. Fill any areas requiring attention. When sanding a previously glued surface, the old adhesive will melt and is very difficult to sweep clean. You may create a bigger problem by sanding unless you entirely remove the old adhesive. If applying filler, remove excess immediately while wet so sanding is unnecessary. If there were any specific areas of discoloration of the vinyl (having definite shape and abrupt edges) then seal the corresponding part of the sub-surface with a deck sealer (brush applied). These areas could include synthetic plywood patches, knot hole, darkened wood grain (pitch pockets). If the existing plywood is not structurally sound, has areas of rot, has excessive inter-ply delamination or splintering due to membrane tear off, etc., consider installing new plywood over existing plywood or with removal of existing plywood. In either case, refer to our technical bulletin #126 “Plywood Deck Construction Recommendations”. Do NOT apply new plywood over existing plywood without removing the existing membrane completely or drilling 2” diameter holes (@16” O.C. throughout) through existing membrane and plywood assembly to reduce the possibility of new plywood rot. Install the new membrane using either Duradek contact or latex adhesives. Latex adhesives can only be used on porous new plywood or existing plywood with complete removal of any existing glue. 2. New Vinyl Over Old: Putting new vinyl over the existing vinyl reduces the possibility of damage to the sub-surface when the old vinyl is removed. 1. Clean the vinyl deck surface thoroughly using a pressure washer and/or scrub with T.S.P. (Tri Sodium Phosphate) or a strong detergent such a Spic and Span. Cleaning product residue must be rinsed off well with fresh water. If there is any grease, oil or other contaminant, they must be completely removed before the sealer and coasting are applied. Care shall be taken not to damage the deck membrane, walls, trims, flashing and surrounding areas with excessive waterpower pressure or force. Page 1 of 2 Please ensure your installers read this bulletin Techtalk 136 Revised – August 2012 New Vinyl Over Old, continued: 2. Completely rinse the vinyl deck surface with clean water to remove any cleaning chemical residue. 3. Allow vinyl deck surface to dry completely and check deck for cleanliness. A clean white glove or several randomly placed strips of masking tape applied, removed and examined may assist in the proper clean determination. Repeat step 1 and/or 2 if necessary. 4. The existing seams need to be either flattened out (by sanding or shaving using a sureform tool) or cut out completely. If they are cut out, there are two different ways to proceed: 1) Apply the filler twice (the first layer will shrink). 2) Leave the seam unfilled. Install the new vinyl by aligning the leading edge into the cut out space, then over lap the adjacent piece of vinyl, as shown in Figure 1. The result will be a seam with no bump. 5. Sweep area clean of debris. 6. Application temperature must be at least 50°F (10°C) and rising with no emanate threat of rain. Do not apply during periods of direct sunlight. 7. Apply one coat of Zinsser BIN Shellac Based Primer Sealer evenly over the thoroughly cleaned membrane to seal the entire surface. Do NOT tint primer. Mix the Zinsser very well before using. It should have a very thick even consistency for proper results. Detail perimeters and around posts with a brush and apply the open areas with a roller. Zinsser cures quickly. Coverage should be 400-450 sq. ft. per US gallon (3.785 liters). Allow coat to cure (dry) for 2 hours or longer to assure bond. Minimize exposure to airborne dust, traffic, and debris. Remove the vinyl from the vertical portions of the perimeter i.e. over the edge of the deck and up the wall (unless it is a roof in which case you leave the vinyl up the wall in its waterproof condition.) Install the new vinyl over top with contact adhesive (because it is a non-porous surface). All edges must be mechanically fastened. If turning up a wall, it must be secured with “L” trim or Mini trim over butyl tape to prevent any shrinkage. If turning up a wall over vinyl (in a roofing situation) use “L” trim, butyl tape and some form of secure waterproofing (caulking or counter flashing). 3. For Method of Application of Deck Coating over Duradek Vinyl Membranes, See Techtalk #128 The above-suggested application recommendations for use in conjunction with Duradek vinyl deck membranes are predicated on test and /or historical data believed to be reliable. Since this application and use are beyond the control of Duradek, no guarantee of the results is offered or provided. Duradek will however, guarantee that the Zinsser BIN Shellac Based Primer Sealer will adhere to the vinyl surface. Guarantees for the coatings must come from the manufacturers themselves. Page 2 of 2 Please ensure your installers read this bulletin