Aluminium Tube SoluTionS

advertisement

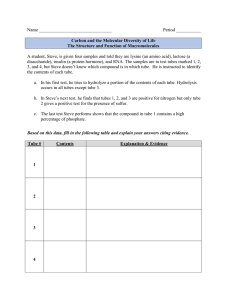

Performance data Increased performances with Hygroove Sapa asked the Danish Technological Institute to measure the heat transfer performances of three of its tubes for fin and tube heat exchangers. The heat transfer coefficient of 9.52mm precision drawn tube, Hygroove tube with straight grooves and Hygroove tube with helical grooves have been measured using a special test set-up1. Based on the tube heat transfer coefficient values, Sapa calculated with a mathematical model the heat transfer coefficient of the overall heat exchanger. Data show that both Hygroove tubes give higher performance results than smooth bore tubes. In particular, compared to precision drawn tube, Hygroove helical tube shows: 1. up to 108% higher heat transfer coefficient of the tube, 2. up to 8% higher heat transfer performances of the overall heat exchanger. Sapa is the world leader in aluminium solutions - a new company that has joined the aluminium extrusion businesses of Sapa and Hydro. Together, we are shaping a lighter future through a global reach and local presence within extrusions, building systems, and precision tubing. We have 23,000 employees in more than 40 countries, and our headquarters are located in Oslo, Norway. ABOUT SAPA’S PRECISION TUBING BUSINESS AREA Overall heat exchanger heat transfer performance Tube heat transfer performance Tube heat transfer coefficient (HTC) at massflux of 200 kg/m2s [W/m2s] Relative improvement compared to PDT [%] Calculated overall heat exchanger heat transfer coefficient [W/m2s] Relative improvement compared to PDT [%] PRECISION DRAWN TUBES 5000 - 576 - HYGROOVE - Straight 6800 +36% 597 +4% HYGROOVE - Helical 10400 +108% 618 +8% 11000 Sapa Precision Tubing is the clear market leader in the field of providing aluminium solutions for heat transfer applications. Our company has 30 years of experience supplying the automotive and the HVAC&R (heating, ventilation, air-conditioning and refrigeration) industries. Beside heat transfer applications, Sapa‘s Precision Tubing Business Area supplies aluminium extruded tubes and welded tubes for gas/ fluid, structural and solar thermal applications. In addition, we also supply niche markets (railway, heavy vehicles, geothermal and other segments) where our technological competence and innovative products can serve our customers. Sapa Precision Tubing has about 2,000 employees at 17 plants and product and process development centers, serving local and global customers all around the world. TEST CHARACTERISTICS 1 Aluminium Tube Solutions Heat transfer coefficient [W/m2K] 10000 (3) Helical Hygroove 9000 • Tubes: OD x WT = 9,52 x 0,6 mm, 6m straight test tube length with refrigerant inside 8000 • (4) Straight Hygroove 7000 6000 (1) Aluminium Smooth 5000 4000 Tube in tube (coaxial) test set up with counter • Refrigerant R410A • Evaporating temperature at 10 ° C • Mass flux between 125 -250 kg/m2s • Inlet vapour quality of 0.1 and outlet vapour • Esther oil: Oil Circulation Rate (OCR) approximately 1% of mass flow 2000 100 150 200 for Fin and Tube Heat Exchangers flow. Water on outer side of test tube quality of 0.9 3000 SALES CONTACT: EUROPE Bjørn Vestergaard T +45 73 71 14 18 E bjorn.vestergaard@sapagroup.com CHINA Shen Yang T +86 512 6283 6368 E yang.shen@sapagroup.com INDIA Sajith Jose T +91 80988 60888 E jose.sajith@sapagroup.com MIDDLE EAST Adil Atiser T +45 73 71 12 21 E adil.atiser@sapagroup.com JAPAN AND KOREA Akira Yamakawa T +86 512 6283 5685 E akira.yamakawa@sapagroup.com NORTH AMERICA Anders Sorensen T +1 321 638 1185 E anders.sorensen@sapagroup.com SOUTH AMERICA Rodolfo Bocato T +55 11 4025 6768 E rodolfo.bocato@sapagroup.com 250 Massflux G [kg/m s] 2 www.sapatubing.com © Sapa 2013 Version 1.1. December 2013 Drop-in solutions for copper replacement why When converting from copper to aluminium or expanding the use of aluminium for additional applications, there are several technical challenges that have to be overcome. Why all-aluminium fin and tube heat exchangers? The heating, ventilation, air conditioning and refrigeration HVAC&R industry has been using mechanically assembled copper tubes and aluminium fin solutions for years. Replacing the copper tubes with aluminium tubes provides tangible benefits: 1. Price per meter 2. Weight per meter The price of aluminium raw material is one-fourth the price of copper1. This will definitely impact your bottom line. Aluminium tubes are 35% lighter than copper, for equivalent burst pressure.2 This improves system weight significantly. 3. Corrosion resistance 4. Performance Corrosion can manifest itself in two ways. First, it can lead to reduced performance of the system, due to galvanic corrosion between tube and fin. In allaluminium heat exchangers, due to a closer galvanic balance between fin and tube, this will occur far later than in a mixed metal - copper tubes and aluminium fins - unit. Of course, care has to be taken in aluminium alloy selection, so that the tube will be more noble than the fin material. Second, corrosion can lead to tube leakages. With proper alloy selection, tube failures will not occur. However for all-aluminium heat exchangers in outside units, Sapa recommends zinc coating of the tubes as extra protection against the possible effects of aggressive environments. In an all-aluminium fin and tube heat exchanger, the tubes have the same thermal expansion coefficient as aluminium fin stock. The bond between tube and fin will be constant regardless of temperature, thus ensuring better heat transfer. In addition, aluminium has less spring-back effect than copper, meaning a better bond between the tube and fin during expansion. Precision drawn tubes straight inner grooved tubes Hygroove Sapa has 30 years of experience supplying the automotive and the HVAC&R industries with solutions and our Applications & Development engineers will support you in every step of the project. From selecting the right dimensions and alloys for your application to providing in-depth knowledge of metallurgy, joining methods and brazing, Sapa has the experience and capability to be your partner. helical inner grooved tubes Hygroove The standard drop-in solution for copper replacement Improved heat transfer with inner grooves The highest performance in heat transfer Precision drawn tubes are the light solution for standard heat exchangers manufactured with mechanically expanded round or oval tubes. The manufacturing process, which includes extrusion, drawing and annealing, guarantees narrow tolerance and a superior surface finish of the tubes. Precision drawn tubes represent an economic alternative to copper. Hygroove is an internally enhanced aluminium tube for high-fin density condensers and evaporators. The inner grooves improve heat transfer, offering higher efficiency by more compact design. Additional Zinc coating layers are available to further increase corrosion resistance, which makes this product a high performing tube. Different grooves depth and geometry satisfy the specific regional requirements and refrigerants in use. The inner grooves are following a helical pattern and have been optimized to improve heat transfer. The improvement in heat transfer coefficient of the tube is two times what can be achieved with traditional smooth bore tubes3. This increased efficiency can help achieve a more compact design of the heat exchangers and a reduction in refrigerant load. Different grooves depth and geometry satisfy the specific regional requirements and refrigerants in use. 3 Choosing aluminium solutions from Sapa is more than choosing the price tag. Sapa provides more than the metal: processability in the customers process and performance in the field are also part of what you get with Sapa as your supplier. Additionally Sapa‘s Research and Development department ensures you will remain at the forefront of technology and continue having the most cost efficient and effective solutions in the market. Refer to the performance data on the backside of this brochure Our tube range at a glance 5. Recyclability Aluminium recycling is important for resource preservation. There is no need to separate different materials in an all-aluminium heat exchanger, thus making recycling easier. Based on avergae LME price from January 1 to November 29, 2013. Primary aluminium, 3-months buyer 1.854 $/kg. Copper grade A, 3-months buyer 7.332 $/kg. Ratio copper/aluminium price=3.96. 4 BURST PRESSURE 4 [PSI] GROOVES DEPTH [mm] NUMBER OF GROOVES GROOVES ANGLE [°] COATINGS KEY FEATURES AVAILABILITY ALLOYS Precision drawn tube Precision drawn tube with smooth inner surface • Easy to form and bend • Low cost and weight • Level wound coils • Cut to length HA3003, HA9158, HA9134M Standard range: 5 to 22 Other OD upon request Standard range: 0.35 to 2 Other WT upon request - - - - - Zinc coating Hygroove straight grooves Precision drawn tube with inner grooved surface • High heat transfer efficiency • Easy to form and bend • Low cost and weight • Level wound coils • Cut to length HA9158, HA9134M 7 7.1 7 9.52 9.52 0.47 0.50 0.50 0.70 0.50 130 145 147 152 106 1900 2000 2100 2150 1500 0.28 0.25 0.30 0.30 0.30 45 40 38 50 50 - Zinc coating HA9158, HA9134M 7 7 7 9.52 9.525 10 0.47 0.50 0.45 0.68 0.50 0.70 130 147 131 147 106 144 1900 2100 1900 2100 1500 2000 0.16 0.16 0.23 0.30 0.18 0.25 48 55 48 40 40 40 18 25 20 20 18 20 NA Hygroove helical grooves For outside diameter of 9.52mm and burst pressure of 123 bar, aluminum tube weight is 46g/m (tube WT=0.6mm, density=2.73g cm3). Copper tube weight is 72g/m (tube WT=0.28mm, density= 8.9g/cm3). OUTER DIAMETER [mm] BURST PRESSURE 4 [bars] PRODUCT DESCRIPTION 1 2 Zinc coating and clad layers for round tubes WALL THICKNESS [mm] Precision drawn tube with inner grooved surface Calculated values for alloy HA9158. Temper O • Very high heat transfer efficiency • Easy to form and bend • Low cost and weight • Level wound coils • Cut to length For heat exchangers operating in aggressive environments, Sapa strongly recommends the addition of a zinc coating to the tubes. This additional layer will provide the tubes with increased corrosion protection and will improve lifetime compared to the equivalent bare tube. This zinc coating is available on smooth bore tubes, and straight inner grooved tubes.