304ta datasheet

advertisement

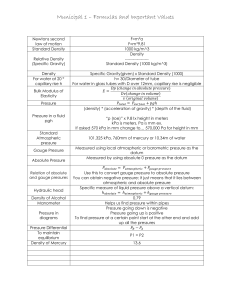

Datum 304 HTA • A precision 304 Stainless thin foil for applications where flatness and uniform gauge are critical. • Exceptional shape control when laser cutting and etching. • Wide range of dimensions and rapid delivery options. The TA Advantage Wide Range of Dimensions Tension annealing (TA) is a specialized process to relieve internal stress while the strip is under tension creating the mechanical properties of a hard temper without the rolling stresses typically induced into a material to produce these properties. This results in a hard material that can be laser cut and etched without shape deformation. Gauge • 0.02mm – 0.50mm (0.8mil – 20mil) • Includes intermediate sizes such as 0.03mm, 0.04mm, 0.06mm, 0.07mm, 0.09mm, 0.11mm, 0.12mm Rapid Turnaround For urgent orders we offer same day shipping. Orders of stock items are shipped within 48 hours. Chemical Composition* Width • <0.35mm (0.14mil): up to 610mm (24”) • >0.35mm (0.14mil): up to 500mm (19.7”) • 0.10, 0.13. 0.15mm (4, 5, 6 mil): up to 690mm (27.2”) Can be slit to required width Length • Sheets up to 2000mm (79”) long 2% Gauge Accuracy Guarantee We deliver certainty on the material gauge far beyond other suppliers Carbon % Max 0.08 Manganese % Max 2.00 Sulfur % Max 0.03 Phosphorous % Max 0.05 Thickness Max Min Max Min Max Min Silicon % Max 1.00 0.08 0.084 0.076 0.083 0.077 0.082 0.078 Chromium % 18.0-20.0 0.09 0.095 0.086 0.094 0.086 0.092 0.088 Nickel % 8.0-10.5 0.10 0.105 0.095 0.104 0.096 0.102 0.098 Nitrogen % Max N/A 0.11 0.116 0.105 0.114 0.106 0.112 0.108 0.12 0.126 0.114 0.125 0.115 0.122 0.118 0.13 0.137 0.124 0.135 0.125 0.133 0.127 5.0% Mechanical Properties* Tensile Strength N/mm2 Min 1130 Yield Strength (0.2% offset) N/mm2 Min 880 % Elongation % Min Hardness VH Surface Roughness (Ra) µm Physical Properties - 7.93 Density g/cm3 370 Young’s Modulus at 68°F (20°C) kg/mm2 19,700 <0.15 Specific Heat (0-100°C) cal/g/°C 0.12 Thermal Conductivity (100°C) cal/sec/cm/°C Electrical Resistivity at 68°F (20°C) mΩ.cm 72 Thermal Expansion Co-efficient (0-100°C) 10 /°C 17.3 *Material produced to JIS standard G 4313 for 304 H. All materials are quality controlled and supplied with certificate of specification © Datum Alloys Ltd 2016 2.0% 4.0% The data says yes -6 0.039 www.datumalloys.com