Wired Together – Engaging Your Employees with Visual Systems

advertisement

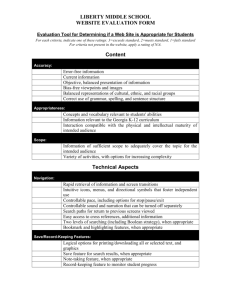

Wired Together – Engaging Your Employees with Visual Systems Tom Lacey Manufacturing Manager, Manchester NH Outline for Today’s Discussion • A bit of our history in Manchester…for context • Visual Displays and Visual Controls • How to Use Visuals to Enhance your Business • Adding instructions & poke-yokes • Engagement, Culture and Visual Systems • Case study – using visual tools to achieve business results Company Profile No. 405 EUROPE & AFRICA REGION AMERICAS REGION ASIA PACIFIC REGION 4,800 Employees 12 Manufacturing Locations 1,800 Employees 10 Manufacturing Locations 8,000 Employees 35 Manufacturing Locations PUBLICLY TRADED 57 MANUFACTURING LOCATIONS IN 26 COUNTRIES 09 TECHNOLOGY CENTERS 13 ALUMINUM & COPPER ROD MILLS 3 rd SALES LARGEST GLOBAL REPRESENTATION & WIRE & CABLE DISTRIBUTION MANUFACTURER WORLDWIDE Manufacturing in a facility built over 100 years ago. View of Jefferson Mill from General Cable Aerial view – General Cable Manchester Coolidge Mill, 345 McGregor Street Main entry, from parking lot Why “Go Visual”? • A common language for your organization to communicate with. • Reduce risk of mistakes (poke-yoke/“errorproofing”). • Puts “control” and “decision-making” in the hands of the people that are performing the tasks. • Improves interaction, engagement, alignment. • Reduces learning and training time. • Improves standard work. Visual Displays vs. Visual Controls • Displays share information. • Controls influence behavior. Visual Displays • Displays communicate or share information. …familiar examples include scoreboards and road signage. Displays can serve many purposes, and they are important - - but they do not directly influence behavior Displays communicate the state, condition, or status to the organization. Visual Displays in Industry From simple signage… …to complex process maps showing relationships between operations Visual Controls • Controls influence behavior. What are the rules of the system? How do you know? Visuals, like language, require interpretation. Red means ? Yellow means ? Green means ? Common language requires commonly accepted definitions. Visual Controls in Manchester For everything from Safety - Scheduling and workflow systems Work in process (WIP) controls Lighting systems to trigger Demand and Replenishment Sign Card-based Replenishment Systems Card out signal Re-Order card Front Back Back Point-of-Use storage with Visual Controls. Spec Define: * Copper • partials Schedule * Copper & Compound return to stock Compound Color concentrate Tips & dies * Hot & Cold welders • Crimpers • Ceramics • Sandpaper Measure: E-12 Primary Extrusion Finished primary wire to cabling Pay-off tools •Allen keys •Collars Reduce “lost time” • Waiting for materials • Searching for needed tools. * = focus items Improve & Controls: * Copper Partials * Copper Return to Stock * Incoming Copper Improve & Controls: * Features Compounds • Blue “returns tag“ = visual signal to remove to basement • Incoming • Return to Stock * Features * Hot & Cold welders Crimpers • 6 tools, labeled by size/OD Features • Ready to use, within reach. A Visual System for Colors Product & level indicators 13 colors, with a Visual Control System An additional example of controls Define: Copper Spec Compound Nylon Color concentrate Schedule Labels Plastic Return to stock Finished wire E-3/E-13 Tips & dies Butt-welder & supplies Pay-off tools * = focus Spools/reels Boxes Contact Printer Ink Jet printers * Controls: * Ink Jet printers Visual Poke-yokes: • Black Printer = Right hand orientation, White Printer = left hand orientation • Printer carts & spaces labeled with colored tape • Cell-specific • All items labeled with “LP number” – designate components to system Control “poke-yokes”: Ink (top shelf) Solvent (bottom shelf) Dedicated wash bottles , labeled & located. Shelf label Clear = white printer Green = black printer Controls – The Visual Standard: This is one of the Keys to Sustain… (reference for “here’s how it should look”). Take 10 seconds… • Write down the top 3 priorities that you wish your employees were 100% committed to and engaged with in your business. Business leaders, what keeps you awake at night? If we surveyed all of your employees, what would they say were the top 3 focus priorities for your business? Manchester’s Scoreboard Wednesday, May 20, 2015 Safety Quality Injuries Customer Returns Internal MRB areas Near Misses Plant Scrap 692 Days Injury Free $2,383 This month CCP $ 5.2% This month Scrap (Target = 4.5%) H-Cord E4, BW E3/E13 - $11.2k - 1/2 day Productivity Plant Volume Service & Delivery First Aid Events Work Order Delivery $ ahead/behind ($1,000) Days ahead/behind Bottleneck Throughput 94.0% 90.0% 92.9% Month-to-Date Last Week Line Fill, MTD DC E15 H-AWG E5, BUC E7/E8, L-Cord E11, L-AWG E2 Spare Dots Creating engagement Monday, October 05, 2015 Safety Injuries First Aid Events Near Misses 830 Days Injury Free • Let your visuals generate emotional attachment. • Celebrate the successes! Would our results be different if we did not• Inject passion? Talk about the details? Celebrate our success every day? Continually reinforce safety first? Can visuals impact Beliefs & Values? Be Kind Please Rewind Visual Information can be a powerful tool for sharing an organization’s values and beliefs. Key points to visual systems • Interpretation of visuals must be clear. • Define the “who” is expected to do “what”, involve fully. • Poke-yoke (reduce chance of errors). • Place the controls in the hands of those who use the system (operator-led process control). • Celebrate the “Are We Winning”. There’s always room for improvement (a simpler, better way). Fully involving the “who” – people. As designed As practiced Simple Is Usually Best We post everything in our value streams – now that’s visual! Q: How do you measure success? A1 – The more, the better. A2 - The critical few. Sometimes, less is more. • Pick the critical few - avoid “wallpaper” • Easier to maintain. Case Study • January 2015 – Manchester, NH • Several incidents of “mixed materials”. • Conditions/States Present: • New associates, training. • Remote location. • Rushing, mind not on task. A kaizen team applies their skills & gets results. The Basement Material (boxes) stored this side of aisle. 4 bays 4 bins Material consumed this side of aisle. Forktruck Aisle Material Storage Area. Material Consumption Area. Sign Surge Bin Boxes (gaylords) stored between columns (bays). Tipper Instructions for forktruck operator: 1. Store correct gaylords in bays opposite tippers 2. Remove empty gaylords from tippers, dispose of properly 3. Move full gaylord across the aisle onto tipper, load material 4” 1” X 3 labels 13-digit part number Tipper 13-digit part number Surge Bin The findings… “It’s simple. Just read the part numbers.” • Did you happen to notice a part number disconnect on the previous slide? Let’s look again… The analysis 1. Poor Lighting in the area – difficult to read. 2. Forktruck drivers must exit the truck to read the 4” x 6” labels. 3. Several part numbers have only 1 digit of differentiation. 4. Bins and signage not consistent or correct in all instances (bin #18 listed part number for 8205 grey). 5. Operator was not aware that he crossed aisleway 1 bay up with the gaylord, and loaded it onto the wrong tipper. Improvement Team starts working - • Added lighting – BIG difference • Remove debris (5S, 5S, 5S…) • Power clean flooring Mistake-proofing • Material-specific color-coding • Added color-coded signage • Color coded tippers, surge bins, and lines Prevention and Detection Poke-yokes Storage Bay sign • Poke-yoke (red) part number highlights. • Circled what to look for. Tipper & Surge Bin sign • Size & shape of compound. • Part number highlights The end product • Column signage 6-months later… • Sustaining. • Adding 1 more bay/surge bin. Visual Systems & ROI (return on investment) • What is the value of a customer to your business? • What is the administrative cost to “fix” or manage the follow-on activity when a mistake happens? The Leader and Standard Work The Power of One Critical mass needed = 1 to trigger change. Influential Leaders vs. Positional Leaders • • Who best can work 1x1 with your associates to introduce change? Early adopters/passive sustainers/aggressive resistors Standard work yields more time to lead change. Do people in your organization know how & what they contribute to the business? Do they also know what is most important to your business? Thoughts on where to start • What three things are vital to your business? • How should we communicate the status of these three things to everyone in our business? • “Business Critical” area • • A “bottleneck” or a constraint Select an area historically challenged with mistakes, misses, upset conditions. • Confidence-builder (low-risk) to foster teamwork. Thank You! Please complete the session survey at: www.ame.org/survey Session: TP/18 Engaging Your Employees with Visual Systems Tom Lacey tlacey@generalcable.com