PM Series

Decorative, Vetro LED Pendant

Page 1 of 2

Project:

Catalog No:

Mfg:

Location:

Fixture Type:

Qty:

Notes:

Lamps:

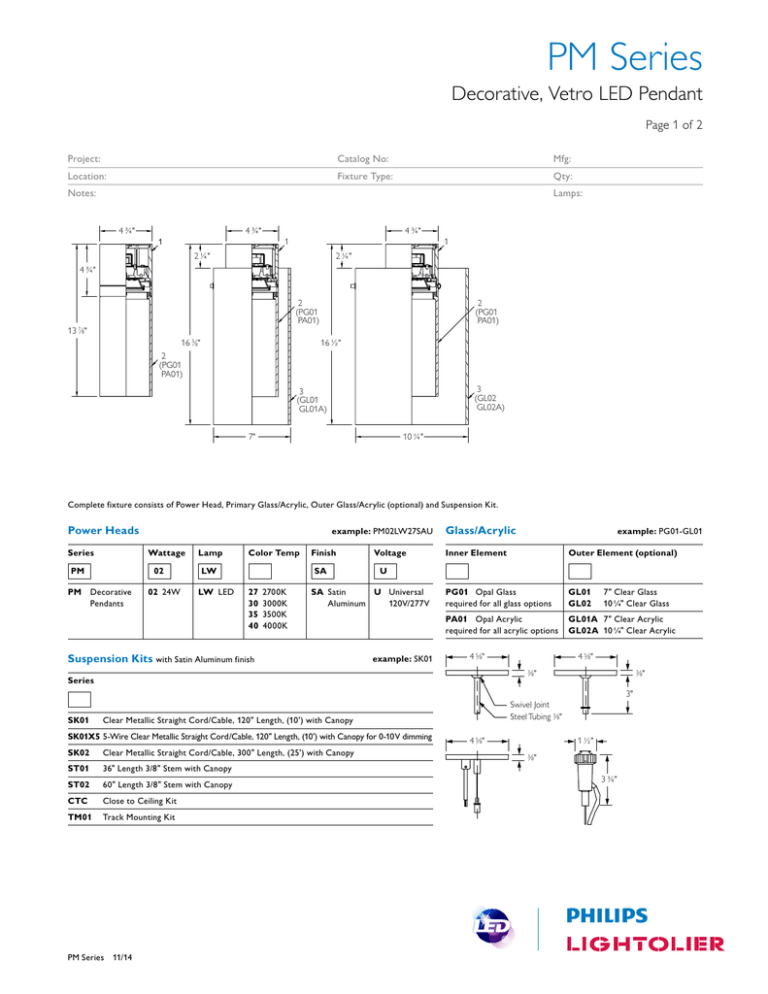

4 ¾"

4 ¾"

1

4 ¾"

1

1

2 ¼"

2 ¼"

4 ¾"

2

(PG01

PA01)

13 78"

16 38"

2

(PG01

PA01)

16 ½"

2

(PG01

PA01)

3

(GL02

GL02A)

3

(GL01

GL01A)

7"

10 ¼"

Complete fixture consists of Power Head, Primary Glass/Acrylic, Outer Glass/Acrylic (optional) and Suspension Kit.

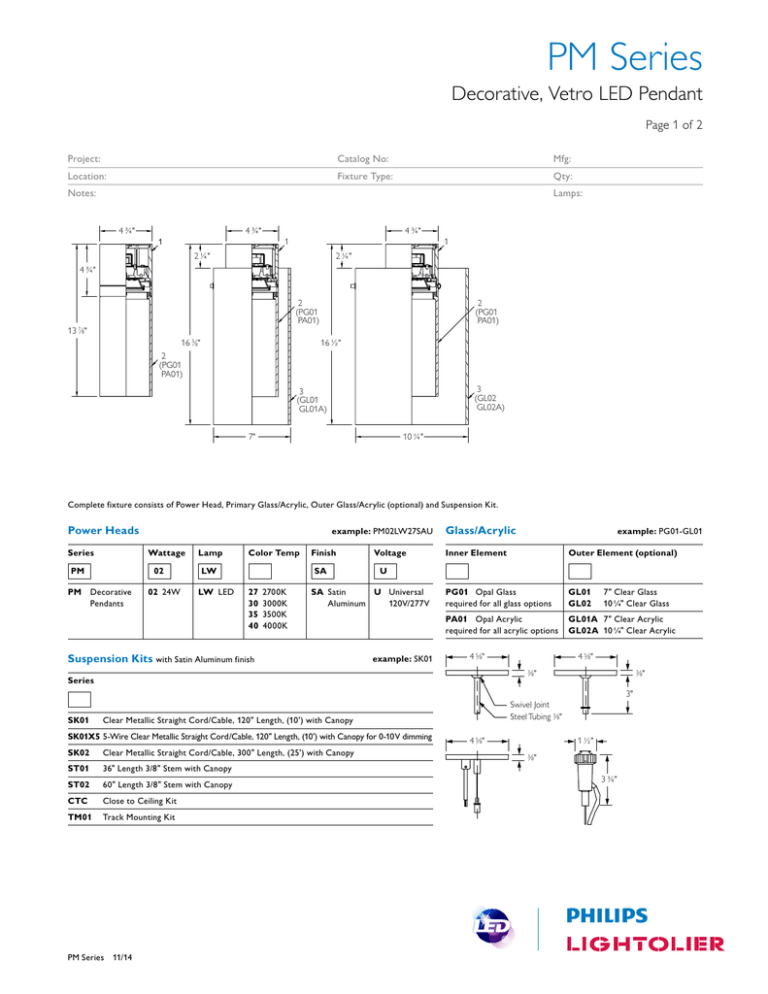

Power Heads

Series

example: PM02LW27SAU

Wattage

PM

02

PM

Decorative

Pendants

02 24W

Lamp

Color Temp

LW

LWLED

Finish

SA

27 2700K

30 3000K

35 3500K

40 4000K

Voltage

Inner Element

Outer Element (optional)

PG01 Opal Glass

required for all glass options

GL01

GL02

PA01 Opal Acrylic

required for all acrylic options

GL01A 7" Clear Acrylic

GL02A 10 ¼" Clear Acrylic

example: SK01

4 58"

7" Clear Glass

10 ¼" Clear Glass

4 58"

"

"

38

Series

SK01

example: PG01-GL01

U

SA Satin

UUniversal

Aluminum

120V/277V

Suspension Kits with Satin Aluminum finish

Glass/Acrylic

SK02

Clear Metallic Straight Cord/Cable, 300" Length, (25') with Canopy

ST01

36" Length 3/8" Stem with Canopy

ST02

60" Length 3/8" Stem with Canopy

CTC

Close to Ceiling Kit

TM01 Track Mounting Kit

PM Series 11/14 3"

Swivel Joint

Steel Tubing 38"

Clear Metallic Straight Cord/Cable, 120" Length, (10') with Canopy

SK01X55-Wire Clear Metallic Straight Cord /Cable, 120" Length, (10') with Canopy for 0-10 V dimming

38

4 58"

1 ½"

"

38

3 ¾"

PM Series

Decorative, Vetro LED Pendant

Page 2 of 2

Features

Electrical

1. Power Head: Die cast and extruded aluminum components.

Brushed and clear lacquer finish.

2. Primary Diffuser: (PG01) Triplex hand blown glass or (PA01) opal

acrylic.

3. Outer Glass/Acrylic Assembly: (GL01) A 7” diameter straight section

of clear extruded glass with polished edges, (GL02) a 10 1/4” diameter

straight section of clear extruded glass with polished edges, (GL01A) a 7”

diameter straight section of clear acrylic, or (GL02A) a 10 1/4” diameter

straight section of clear acrylic. All outer assemblies come with a die cast

aluminum holder ring with stainless steel support pins.

4. Optical Mixing Chamber: Remote phosphor technology provides

increased efficiency and color stability. Phosphor lens assembly positioned

in front of LED array converts blue light to white and produces a wide

even pattern of diffused light without bright spots created by individual

LEDs. Uniform phosphor coating provides consistent, stable color with

a shift of no more than +/-100K over life. Mixing chamber redirects

scattered light back out through the emitting aperture.

5. Thermal Management: Heat sink design maintains junction

temperature for consistent, reliable performance and 50,000 hour lifetime

at 70% lumen maintenance.

LED Board: Array of high brightness white LEDs.

Electronic Power Supply: 120 or 277V, 50/60Hz, encased, overload and short

circuit protected, thermal regulation to protect against overheating, sound rating

“A”, -20° C minimum starting temp, 40° C maximum operating temp.

Dimming Capability: 0-10 V, see suspension options.

Input

Voltage

Input

Frequency

LED Drive

Current

Input

Power

THD

Power

Factor

120V

277V

50/60Hz

50/60Hz

350mA

350mA

24W*

24W*

<5%

<10%

>0.9

>0.8

*+/-5%

Labels

cULus for damp locations.

PM01LW35SAU

Report No.: 202GFR

Total Fixture Lumens: 1051 lm

Color Temp: 3500K

Input Watts: 24.3W

Luminaire Efficacy: 43.3 lm/w

CRI: 80 min.

0

200

60°

400

Zonal Lumens and Percentages

Zone

Lumens

%Fixt

600

800

30°

0-30

0-40

0-60

0-90

90-180

0-180

195

254

396

659

392

1051

19

24

38

63

37

100

Candela Array

Angle Mean CP

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

736

754

746

143

147

130

106

94

89

86

85

84

85

85

85

84

84

82

Vertical Angles

Angle Mean CP

90

95

100

105

110

115

120

125

130

135

140

145

150

155

160

165

170

175

81

82

81

79

77

74

69

65

60

55

50

43

37

30

23

15

5

1

Coefficients Of Utilization - Zonal Cavity Method

Effective Floor Cavity Reflectance 0.20

RC

80

70

50

RW 70 50 30 70 50 30 50 30 10

0

101 101 101 103 103 103 90 90 90

1

98 92 87 91 86 82 75 72 68

2

88 80 72 82 75 68 65 60 55

3

81 70 62 75 66 58 57 52 47

4

74 63 54 69 59 51 52 46 41

5

69 56 48 64 53 45 47 40 36

6

64 51 43 59 48 40 43 36 32

7

59 47 38 55 44 37 39 33 29

8

56 43 35 52 41 33 36 30 26

9

52 40 32 49 38 31 34 28 24

10

49 37 30 46 35 28 32 26 22

Effective Floor Cavity Reflectance 0.20

0

0

63

47

38

32

29

25

23

21

19

18

17

Power head tested using absolute photometry as specified in LM79: IESNA

IESNA approved method for the electrical and photometric

Approved Method for the Electrical and Photometric Measurements of Solid-State measurements of solid-state lighting products.

Lighting Products. Luminaire with glass tested by relative photometric method.

© 2014 Koninklijke Philips N.V. All rights reserved.

Philips reserves the right to make changes in specifications

and/or to discontinue any product at any time without notice

or obligation and will not be liable for any consequences

resulting from the use of this publication.

PM Series 11/14 page 2 of 2 philips.com/luminaires

Philips Lighting,

North America Corporation

200 Franklin Square Drive,

Somerset, NJ 08873

Tel. 855-486-2216

Imported by: Philips Lighting,

A division of Philips Electronics Ltd.

281 Hillmount Rd, Markham, ON,

Canada L6C 2S3

Tel. 800-668-9008