POLARITY AND IMPEDANCE TESTING

advertisement

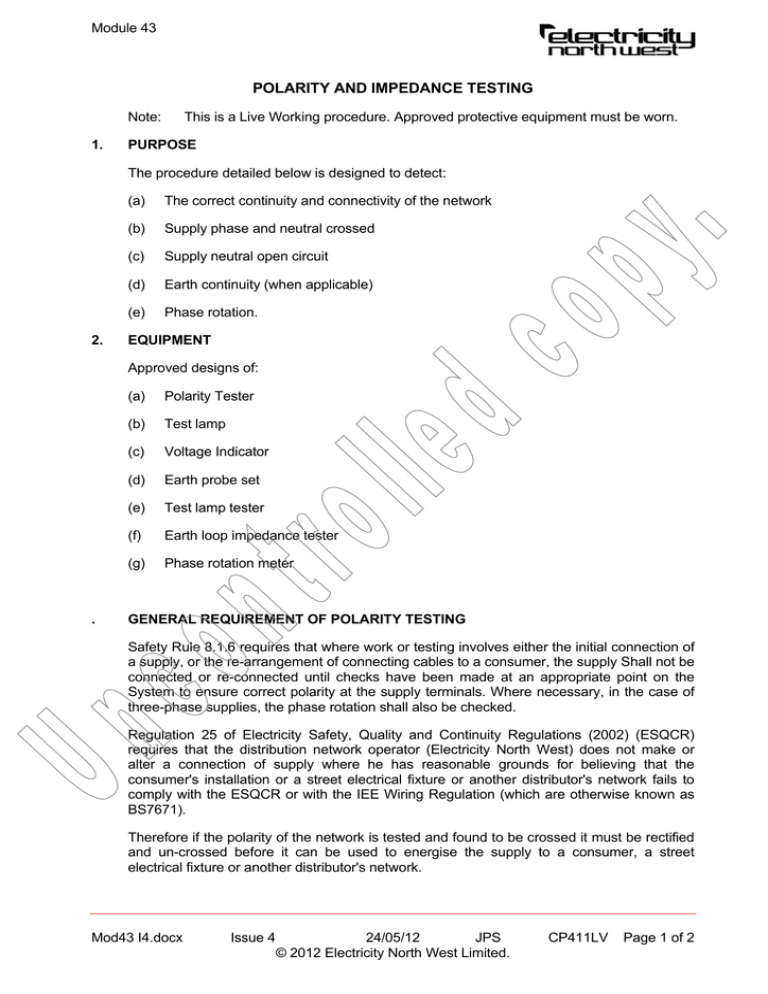

Module 43 POLARITY AND IMPEDANCE TESTING Note: 1. This is a Live Working procedure. Approved protective equipment must be worn. PURPOSE The procedure detailed below is designed to detect: 2. (a) The correct continuity and connectivity of the network (b) Supply phase and neutral crossed (c) Supply neutral open circuit (d) Earth continuity (when applicable) (e) Phase rotation. EQUIPMENT Approved designs of: . (a) Polarity Tester (b) Test lamp (c) Voltage Indicator (d) Earth probe set (e) Test lamp tester (f) Earth loop impedance tester (g) Phase rotation meter GENERAL REQUIREMENT OF POLARITY TESTING Safety Rule 8.1.6 requires that where work or testing involves either the initial connection of a supply, or the re-arrangement of connecting cables to a consumer, the supply Shall not be connected or re-connected until checks have been made at an appropriate point on the System to ensure correct polarity at the supply terminals. Where necessary, in the case of three-phase supplies, the phase rotation shall also be checked. Regulation 25 of Electricity Safety, Quality and Continuity Regulations (2002) (ESQCR) requires that the distribution network operator (Electricity North West) does not make or alter a connection of supply where he has reasonable grounds for believing that the consumer's installation or a street electrical fixture or another distributor's network fails to comply with the ESQCR or with the IEE Wiring Regulation (which are otherwise known as BS7671). Therefore if the polarity of the network is tested and found to be crossed it must be rectified and un-crossed before it can be used to energise the supply to a consumer, a street electrical fixture or another distributor's network. Mod43 I4.docx Issue 4 24/05/12 JPS © 2012 Electricity North West Limited. CP411LV Page 1 of 2 Module 43 3. SINGLE PHASE TERMINATION POLARITY TEST Follow either the procedure detailed in Appendix A or Appendix B. 4. THREE PHASE TERMINATION POLARITY TEST Follow the procedure detailed in Appendix C. 5. IDENTIFICATION AND TESTING OF NEUTRAL OF THE FOUR CORE PILC CABLE 5.1 Initially identify the neutral by the number of the core paper (or by the colour of the paper on older cables). 5.2 Test for supply and confirm neutral core identification using the approved test lamps. 5.3 If the cable is Dead, the neutral shall be correctly identified as set out in CP606, procedure B14. 5.4 In all cases connect the test lamp between the neutral and lead sheath no matter whether the cable is Live or Dead. If even the slightest glow is seen in the test lamp bulb act as follows: (a) Stop the works and keep everyone away from the cable. (b) Notify the Fault Desk. The glow is caused by the presence of an unexplained voltage between the neutral and the cable sheath. This may be due to a number of things such as: Out-of-balanced load Induced voltage A neutral fault Do not restart work until the cause of the voltage has been investigated, identified and the appropriate action has been confirmed. 6. PHASE ROTATION TESTING Follow the procedure detailed in Appendix D. 7. EARTH LOOP IMPEDANCE TESTING Follow the procedure detailed in Appendix E. 8. EARTH ELECTRODE IMPEDANCE TESTING Follow the procedure detailed in Appendix F. Mod43 I4.docx Issue 4 24/05/12 JPS © 2012 Electricity North West Limited. CP411LV Page 2 of 2 Module 43 APPENDIX A TEST FOR CORRECT POLARITY OF A SINGLE PHASE TERMINATION USING A POLARITY TESTER IN PERFORMING THIS TEST: 1. The polarity tester shall be confirmed to be working correctly using approved proving device. 2. If Electricity North West is providing a reliable earth, any Neutral – Earth bonding link in the cutout must be temporarily disconnected, before the polarity test can be carried out. 2 Remove the fuse carrier, identify and temporarily disconnect consumer’s neutral and earth wires - assume that the neutral/earth block is live. 4 Test to identify the live conductors by using polarity tester 5 Confirm the correct polarity by connecting the Polarity tester probe to: 5.1 The lower fuse base terminal (test pen should glow red and the buzzer will sound) 5.2 The neutral block (test pen should not glow red and the buzzer will not sound) 6. Check Polarity Indicator is working by repeating 1. above 7. If the test result indicate correct polarity work should continue to its conclusion. 8. If the correct indications are not obtained then the situation must be reported to the Fault Desk as a Cross Polarity Incident. The work in hand may then proceed, which must include rectification of the cross polarity. 9. After completing the required rectification on the network or service cable terminations, retesting shall be carried out as necessary. If the correct indications are obtained re connect the consumer’s neutral and earth wires and replace the fuse carrier. Seal the cutout. Mod43 I4.docx Issue 4 24/05/12 JPS © 2012 Electricity North West Limited CP411LV Page A1 of 1 Module 43 APPENDIX B TEST FOR CORRECT POLARITY OF A SINGLE PHASE TERMINATION USING TEST LAMP, VOLTAGE INDICATOR OR VOLTMETER IN PERFORMING THIS TEST: 1. The test lamp, voltage indicator or voltmeter shall be confirmed to be working correctly using approved proving device. 2. If Electricity North West is providing a reliable earth any Neutral – Earth bonding link in the cutout must be temporarily disconnected, before the polarity test can be carried out. 3. Remove the fuse carrier, identify and temporarily disconnect consumer’s neutral and earth wires - assume that the neutral/earth block is live. 4 Test to identify the live conductors by using the test lamp, voltage indicator or voltmeter. OR Mod43 I4.docx Issue 4 24/05/12 JPS © 2012 Electricity North West Limited CP411LV Page B1 of 2 Module 43 5 Confirm the correct polarity by connecting the test lamp, voltage indicator or voltmeter between: 5.1 The lower fuse base terminal and earth (the test lamp and voltage indicator should light or the voltmeter should read 230 volts ± 20volts). 5.2 The neutral block and earth (the test lamp and voltage indicator should not light or the voltmeter should read less than 20volts). 6. Check Polarity Indicator is working by repeating 1. above 7. If the test result indicate correct polarity work should continue to its conclusion. 8. If the correct indications are not obtained then the situation must be reported to the Fault Desk as a Cross Polarity Incident. The work in hand may then proceed, which must include rectification of the cross polarity. 9. After completing the required rectification on the network or service cable terminations, retesting shall be carried out as necessary. If the correct indications are obtained re connect the consumer’s neutral and earth wires and replace the fuse carrier. Re-test the polarity at a socket on the consumer’s installation. Seal the cutout. Mod43 I4.docx Issue 4 24/05/12 JPS © 2012 Electricity North West Limited CP411LV Page B2 of 2 Module 43 APPENDIX C TEST FOR CORRECT POLARITY OF A THREE PHASE TERMINATION USING TEST LAMP, VOLTAGE INDICATOR OR VOLTMETER 1. Remove the fuse carriers. 2. Identify and disconnect the consumer’s neutral and earth wires, (assume that the neutral/earth block and PME link is Live). 3. Disconnect the PME link (when fitted). 4. The test lamp, voltage indicator or voltmeter shall be confirmed to be working correctly using approved proving device. 5. Test for supply and polarity, carrying out tests 1 to 4 in order. Mod43 I4.docx Issue 4 24/05/12 JPS © 2012 Electricity North West Limited CP411LV Page C1 of 2 Module 43 5. Tests 3 and 4 are not applicable to CNE type cables. 6. If the correct indications are not obtained then the situation must be reported to the Fault Desk as a Cross Polarity Incident. The work in hand may then proceed, which must include rectification of the cross polarity. 7. After completing the required work, re-testing shall be carried out as necessary. If the correct indications are obtained re-connect the consumer’s neutral and earth wires and replace the fuse carrier. Re-test the polarity at a socket on the consumer’s installation. Seal the cutout. Mod43 I4.docx Issue 4 24/05/12 JPS © 2012 Electricity North West Limited CP411LV Page C2 of 2 Module 43 APPENDIX D TEST FOR CORRECT PHASE ROTATION 1. TO PROVE CONTINUITY AND TO ASCERTAIN FAULTY LINE IF CONTINUITY IS NOT PROVED. In order to carry out a valid phase rotation test it is necessary to have three phases and a neutral available, with correct polarity. Before commencing any test to indicate the rotation of phases, the polarity test as set out in Appendix C shall be carried out. Any discrepancy with the polarity of the connection must be corrected before continuing with the phase rotation test. 2. TO ASCERTAIN THE SEQUENCE OF PHASE ROTATION. Connect the phase rotation meter using approved fused test leads. These will include at least one of the test probes being fitted with a crocodile clip to ensure safety whist handling the remaining leads. Additional detachable crocodile clips should be fitted to the other leads, as appropriate, in order to be able to make safe connection to the terminals under test, whilst operating and reading the instrument. The direction of rotation should be noted. 3. TO PROVE CONSISTENCY OF PHASING ACROSS THE NETWORK. Connect the leads to the terminals at a known and trusted reference point elsewhere on the distribution network and note the rotation. This can then be compared to the results of a test at the incoming terminals of the cutout, or elsewhere. If there is correct continuity without a cross then the direction of rotation will be the same. Caution: Crossed phasing should not be confused with crossed polarity. Crossed phasing does not present an electrically unsafe situation. The phases may have been crossed deliberately to ensure the correct operation of three phase equipment connected further down the circuit or within a specific premise. No attempt to should be made to alter the connections and rotation without further investigation, which shall involve making sufficient checks with the consumer to confirm correct operation of their equipment. 4. TO PROVE CONSISTENT ROTATION AT THE CONSUMER’S PREMISES. Where consumers operate rotating machinery checks should be made to check that the machinery is operating correctly, i.e. correct rotation of motors, etc. If connection need to be broken and re-made in the course of work these checks must be made before and after to ensure no change to the phasing has occurred Mod43 I4.docx Issue 4 24/05/12 JPS © 2012 Electricity North West Limited CP411LV Page D1 of 1 Module 43 APPENDIX E TEST TO DETERMINE THE EARTH LOOP IMPEDANCE Note: This is a Live procedure, 1000V rubber gloves must be worn. (a) Connect the dual test lead socket to the recessed plug in the instrument. (b) Set the slider switch to the appropriate range (TN). (c) Connect the black prod to the earth terminal. (d) Connect the red prod to the phase. (e) Check that the ‘P-E’ neon light illuminates. (If result is not displayed, repeat the test by disconnecting and then reconnecting one of the probes.) (f) Wait approximately 4 seconds and read displayed result. (If result is not displayed, repeat the test by disconnecting and then reconnecting one of the probes.) (g) Compare the result obtained with Table 1 below:If the result is greater than the worse case figure, report this to the Supervisor. Table 1 Mod43 I4.docx System Worse Case Reading TNS (separate earth) 0.8 TN-C-S (PME) 0.35 Issue 4 24/05/12 JPS © 2012 Electricity North West Limited CP411LV Page E1 of 1 Module 43 APPENDIX F EARTH ELECTRODE TESTING USING THE DET 3/2 MEGGER DIGITAL EARTH TESTER Note: Approved protective equipment must be worn (See Section 2) FALL OF POTENTIAL METHOD WITH SHORT ‘E’ LEAD Make connections to the earth electrodes ‘E’, ‘P’ and ‘C2’. Press the button labelled ‘C1-P1’ (‘E-ES’) to automatically connect these two terminals internally. This should only be done if the test lead can be kept short because resistance will be included in the measure measurement. Note: Earth Electrode test lead resistance can be determined separately. First remove it from the electrode ‘E’ and connect it to the ‘C2’ and ‘P2’ (or ‘H’ and ‘S’) terminals joined together, then measure its resistance in the normal way. This lead resistance can then be deducted from the earth resistance measurements. This procedure is not, of course, necessary if the ‘C1’ and ‘P1’ (or ‘E’ and ‘S’) terminals are connected by separate test leads. 15m to 25m 15m to 25m 3m 3m E C2 P2 Electrode under test 200 2k 20 E ES S H C1 P1 P2 C2 20k Off Rev/min Lo E C1 ES P1 Test RP Figure 11 Mod43 I4.docx Issue 4 Noise Bruit RP Rc max MEGGER DET 3/2 Earth Tester Fall of Potential method using single lead to the earth electrode 24/05/12 JPS © 2012 Electricity North West Limited CP411LV Page F1 of 1