Compressed Air Systems

advertisement

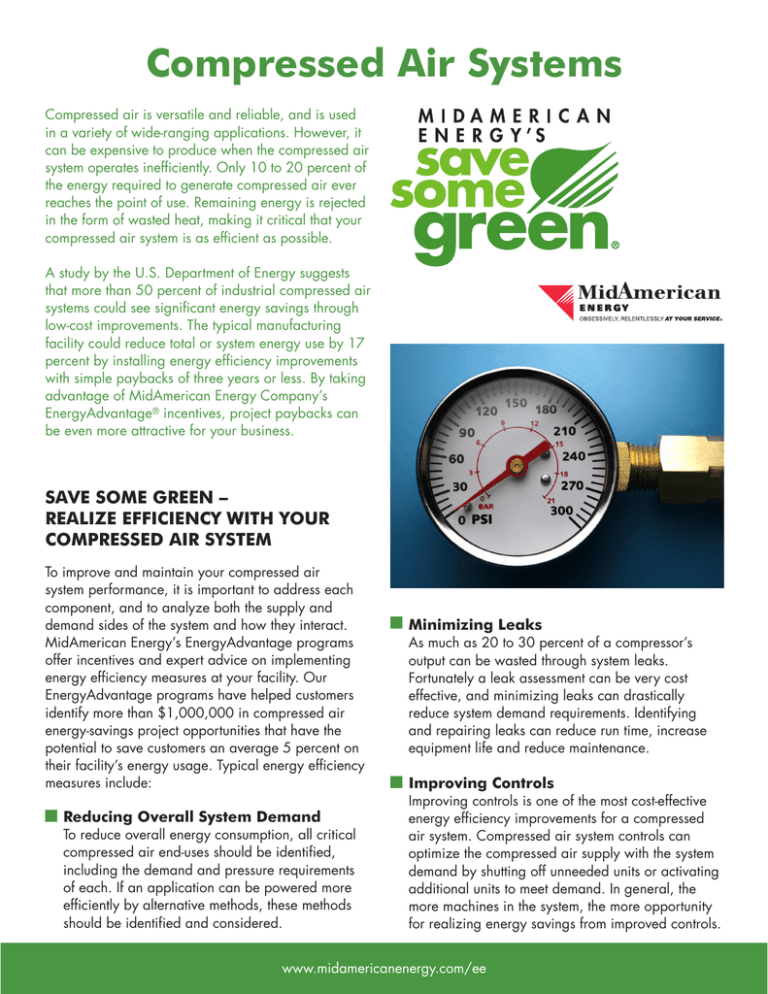

Compressed Air Systems Compressed air is versatile and reliable, and is used in a variety of wide-ranging applications. However, it can be expensive to produce when the compressed air system operates inefficiently. Only 10 to 20 percent of the energy required to generate compressed air ever reaches the point of use. Remaining energy is rejected in the form of wasted heat, making it critical that your compressed air system is as efficient as possible. A study by the U.S. Department of Energy suggests that more than 50 percent of industrial compressed air systems could see significant energy savings through low-cost improvements. The typical manufacturing facility could reduce total or system energy use by 17 percent by installing energy efficiency improvements with simple paybacks of three years or less. By taking advantage of MidAmerican Energy Company’s EnergyAdvantage® incentives, project paybacks can be even more attractive for your business. SAVE SOME GREEN – REALIZE EFFICIENCY WITH YOUR COMPRESSED AIR SYSTEM To improve and maintain your compressed air system performance, it is important to address each component, and to analyze both the supply and demand sides of the system and how they interact. MidAmerican Energy’s EnergyAdvantage programs offer incentives and expert advice on implementing energy efficiency measures at your facility. Our EnergyAdvantage programs have helped customers identify more than $1,000,000 in compressed air energy-savings project opportunities that have the potential to save customers an average 5 percent on their facility’s energy usage. Typical energy efficiency measures include: Reducing Overall System Demand To reduce overall energy consumption, all critical compressed air end-uses should be identified, including the demand and pressure requirements of each. If an application can be powered more efficiently by alternative methods, these methods should be identified and considered. Minimizing Leaks As much as 20 to 30 percent of a compressor’s output can be wasted through system leaks. Fortunately a leak assessment can be very cost effective, and minimizing leaks can drastically reduce system demand requirements. Identifying and repairing leaks can reduce run time, increase equipment life and reduce maintenance. Improving Controls Improving controls is one of the most cost-effective energy efficiency improvements for a compressed air system. Compressed air system controls can optimize the compressed air supply with the system demand by shutting off unneeded units or activating additional units to meet demand. In general, the more machines in the system, the more opportunity for realizing energy savings from improved controls. www.midamericanenergy.com/ee Optimizing System Pressure Setpoint Using more pressure than is required to run equipment increases energy consumption and compressed air costs. Reducing the system supply pressure in small increments can determine if a system’s pressure is set higher than optimal. For every 2-psig reduction in compressor discharge pressure, compressor energy use can be reduced by 1 percent. Installing High-Efficiency Air Nozzles High-efficiency air nozzles can reduce compressed air consumption by projecting a precise jet of air for blow-off applications. Installing high-efficiency air nozzles can reduce compressed air application demand by 50 percent or more and also can reduce perceived noise levels. Nonresidential Energy Savings MidAmerican Energy’s customers who have completed energy efficiency measures through the EnergyAdvantage nonresidential programs have seen favorable paybacks and savings. The energy efficiency measure savings have been up to $20,000, with paybacks as shown in the table below. Paybacks are shown without incentives, and incentive eligibility for these measures may vary. Contact MidAmerican Energy for details. Energy Efficiency Measure Paybacks Less Than Repairing leaks* 1.5 years Improving controls 3 years Optimizing pressure setpoint 2 years Installing No-Loss Condensate Drains Installing high-efficiency air nozzles 1 years Removing condensate is important for maintaining the appropriate air quality level. However, significant energy can be wasted if condensate removal is done with timer drains or cracked-open valves. By installing a no-loss condensate drain, compressed air is saved and air quality levels are improved. Installing no-loss condensate drains 1 years NEXT STEPS AND AVAILABLE FINANCIAL INCENTIVES MidAmerican Energy’s EnergyAdvantage programs are designed to put the power of energy efficiency in the hands of our residential and business customers. For business customers interested in increasing the efficiency of their compressed air systems, the Nonresidential Custom Systems and Nonresidential Energy Analysis programs are available. To learn more about MidAmerican Energy’s EnergyAdvantage savings or energy efficiency improvements, call your MidAmerican Energy representative at 800-894-9599 or visit www.midamericanenergy.com/ee. * Repairing leaks is an extremely cost-effective energy efficiency measure; EnergyAdvantage incentives are not available for this measure. RESOURCES The Advanced Manufacturing Office www.eere.energy.gov/industry/bestpractices AIRMaster+ www1.eere.energy.gov/manufacturing/tech_ deployment/software_airmaster.html U.S. DOE Compressed Air Tip Sheets www1.eere.energy.gov/manufacturing/tech_ deployment/compressed_air.html The Compressed Air Challenge www.compressedairchallenge.org QUESTIONS? Call MidAmerican Energy at 800-894-9599 with questions about application procedures, qualifying projects, incentives or verification procedures. www.midamericanenergy.com/ee