Lab Manual

advertisement

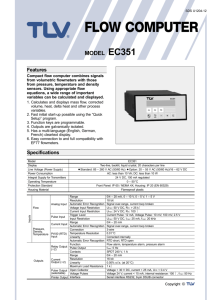

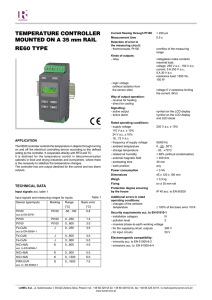

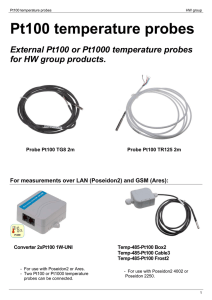

Lab Manual RTD PT-100 Platinum Resistance Temperature Detector - 100 Ohm at 0oC Prepared by Tam Hai-Dang Nguyen ElectroMechanical Energy Laboratory April 2013 1 Contents 1. Introduction ...............................................................................3 2. Circuit board .............................................................................4 3. Data acquisition system ............................................................8 4. Procedure ................................................................................10 Appendix - PT100 Temperature / Resistance Table ...................13 2 1. Introduction This manual will introduce you to the PT100 and describe its function so you can make the best use of your new instrument. Product specification: 1. Body is ceramic 2. Temperature range: -200 oC to 350 oC 3. Size: Ф1.5 x 16(L) mm 4. Order: http://shop.cpu.com.tw/product/8798/info/ Figure 1 Circuit Schematic: Figure 2 3 2. Circuit board Simulation of the circuit in Proteus software: LM324 Pin7 Voutput RVA RVB Figure 3 Varistors RVA and RVB are used to control the output voltage at pin 7 of LM324. Using negative feedback (non-inverting amplifier) Figure 4 Vout Rf ≈ Vin 1 + Rg (1) 4 The output voltage of the circuit equals: (Tam figured out by experiment) Voutput = (VPT 100 − VRA ) × k RB (2) The linear properties of RTD PT100: Figure 5 Calibration: by adjusting the varistors RVA RVB (see figure 3), we can make the voltage line pass through desired values (0.25V at 25oC, 0.9V at 90oC). Then, reading temperature (T) of PT100 will correspond to the output voltage (Vout): T = 100*Vout Figure 6 5 The completed circuit board in cover box: Power LED RB RA PT100 Figure 7 PT100 Power LED Power (+) Power (-) 6 mm power jack Figure 8 Output (+) Output (-) BNC adapter 6 Specification: 1. Power supply: 7-15 V plug in 6 mm jack or power jacks (+)/(–) 2. Power LED indicator 3. 2 output ways: outputs (+)/(–) or BNC adapter The construction of a ceramic PT100: PT100 Object Figure 9 Measuring temperature by PT100’s body is better than by its tip. To get the accurate temperature of the object, there should be a layer of thermal grease (also called thermal paste, thermal compound) between PT100’s body and object’s surface. Figure 10 7 3. Data acquisition system DAQ software: LabVIEW with NI-9234 card (4-Channel, ±5 V, 24-Bit, IEPE and AC/DC Analog Input Module) Figure 11 DAQ system: Figure 12 8 The user interface in LabVIEW: The block diagram: Figure 13 Figure 14 Measure temperature of 3 channels. DAQ assistant block reads voltages from 3 PT100 boxes, plots them in graph and writes to 3 data files (temp1.lvm, temp2.lvm, temp3.lvm) in the same folder. Temperature T [oC] = 100*Vchannel 9 4. Procedure 1. Connect PT100 boxes to NI-9234 (see figure 8 on page 6). - option 1: using output(+) and output(–). - option 2: using BNC connection. 2. Use USB communication between NI-9234 card and computer. 3. Start LabVIEW program, configure DAQ assistant block (config. steps in the following). 4. Run the program: 2 options - normal run: collect data, plot graph and write to files (*.lvm). - run continuously: for testing. Configuration steps: 1. Add a voltage channel, select an analog input from ai0 to ai3. Voltage 10 ai0 to ai3 Coupling mode Signal range Rate (Hz) Acquisition mode Samples to read 2. Signal input range is ±5 V. 3. Coupling mode is DC. 4. Acquisition mode is N samples. 5. Rate (Hz) equals 10k. 6. Samples to read equals running time x rate (set 10k if 1s run). 11 Timeout (s) 7. Advanced Timing tab: set timeout value ≥ running time. 12 Testing reading temperature of hot water with 3 PT-100: 1. Pour hot water into a cup. 2. Use reading temperature of IR camera as reference (72.5oC). 3. Do all procedure steps, normal run, sampling time equals 12s. 4. Temperature T [oC] = 100*Vchannel = 100* 0.73 = 73 13 Appendix - PT100 Temperature / Resistance Table 14 15