Remote Assist systems - Bender-UK

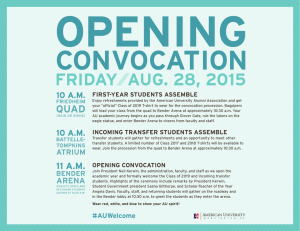

advertisement