Cut-off Frequency Enhanced Hybrid Electromagnetic Bandgap (EBG

advertisement

Cut-off Frequency Enhanced Hybrid Electromagnetic Bandgap (EBG)

Structures with Wideband Noise Suppression Characteristics

Ki Hyuk Kim, Pavle Milosevic, and José E. Schutt-Ainé

Department of Electrical and Computer Engineering, University of Illinois,

Urbana, IL 61801 USA

E-mail: {khkim, pavle, jschutt}@emlab.uiuc.edu

Abstract: A cut-off frequency characteristic enhanced hybrid EBG structure is proposed. In the

proposed EBG structure, inductive bridges between neighboring metal patches are designed

using lumped chip inductors instead of conventional microstrip lines. From 75 MHz to 4830

MHz a stopband bandwidth of 4.755 GHz is achieved at a -30 dB noise suppression level.

Introduction

Due to continuous increase of CMOS device cut-off frequencies (fTs) single

chip integrations of high speed mixed-signal systems are widely researched. One

of the design and testing issues of such high speed mixed-signal designs is the

simultaneous switching noise (SSN) coupling through solid power/ground plane

pairs. The increased operating speed of digital blocks results in large SSN, which

degrades not only the noise margins of digital circuits, but also the performance of

analog circuits. At PCB/package level, the generated SSN can propagate through

parallel plate waveguides which are formed by the solid power/ground plane pairs.

In order to suppress the noise coupling at the PCB/package level, Wu et al.

used a uniplanar EBG structure in the design of the power/ground plane pairs [1].

The uniplanar EBG structure consists of a 2-dimensional array of metal patches

and microstrip line bridges between the neighboring patches. Wu’s EBG structure

showed a wideband noise suppression characteristic with a 3 GHz stopband

bandwidth, however, due to low inductance of the bridges the stopband cut-off

frequency of the EBG structure was around 1 GHz. In order to reduce the cut-off

frequency, several high inductance microstrip line bridges are proposed [2], [3].

However, the lowest cut-off frequency of the previously reported EBG structures

is around 300 MHz, which is still higher than the clock frequencies of current

mixed-signal systems.

In this work, an EBG structure with VHF-band cut-off frequency is proposed

by replacing the microstrip line bridges with lumped chip inductors. A onedimensional analysis model is developed to provide the mathematical foundation

for the use of lumped chip inductors in the EBG structure design.

One-Dimensional Analysis of Planar EBG Structure

Fig. 1 shows a one-dimensional equivalent circuit of the planar EBG

structure, where a and g are the center-to-center distance and the gap size between

1-4244-0878-4/07/$20.00 ©2007 IEEE

2913

(i-1)th Cell

(i+1)th Cell

ith Cell

Cgap

b

LP/2

LP/2

CP/2

CP/2

LL

Cparasitics

b

LP/2

CP/2

g

d

a

ith Patch

Bridge

εr

(i+1)th Patch

Fig. 1. One-dimensional Equivalent Circuits of the EBG structure

two neighboring patches, respectively, b is the width of the rectangular patches,

and d is the height of the dielectric substrate. LP and CP are the inductance and the

capacitance of each square metal patch, respectively, LL is the inductance of the

bridge, and CT is the series parasitic capacitance between two patches including

the gap capacitance (Cgap) and the parasitic capacitance of the bridge (Cparasitics).

LP, CP, and Cgap can be calculated using published quasi-static models [4].

Cparasitics varies depending on the physical implementation of the bridges, and

typical values of Cparasitics for lumped chip inductors are less than 0.24 pF [5]. Cgap

is larger than Cparasitics under the condition that b⋅(1+εr) is larger than

Cparasitics⋅(118.6e+12) mm for the EBG structures with g=0.1⋅a. For the 0.24 pF

series parasitic capacitance, the calculated value of Cparasitics⋅(118.6e+12) is 28.5

mm, which is only 22.6 % of the calculated values of b⋅(1+εr) using parameters of

the previous EBG structures [1–3]. The capacitances ratio Cgap/CP is very small

for typical PCB/package structures, since the values of b are much larger than

those of d. The typical value of d is in the range of 0.4 – 1.6 mm, and the width of

the patches is around 30 mm [1–3].

By applying the image parameter method [4] and the above two capacitance

ratios, the lower (flower) and upper (fupper) cut-off frequencies of Fig. 1 can be

derived as

[

f lower = π C P (LP + LL )

[

]

−1

f upper = 2π CT C P LP (4CT + C P )

(1)

]

−1

.

(2)

flower and fupper are not related to CT and LL, respectively. That is, although

lumped chip inductors have low self resonant frequencies (SRFs) due to their

series parasitic capacitances, the cut-off frequency of the EBG structure can be

lowered by using the high inductance chip inductors as the bridges. And the

replacements cause no degradation of the other high frequency characteristics.

2914

Design and Experimental Verification of Proposed Hybrid EBG Structure

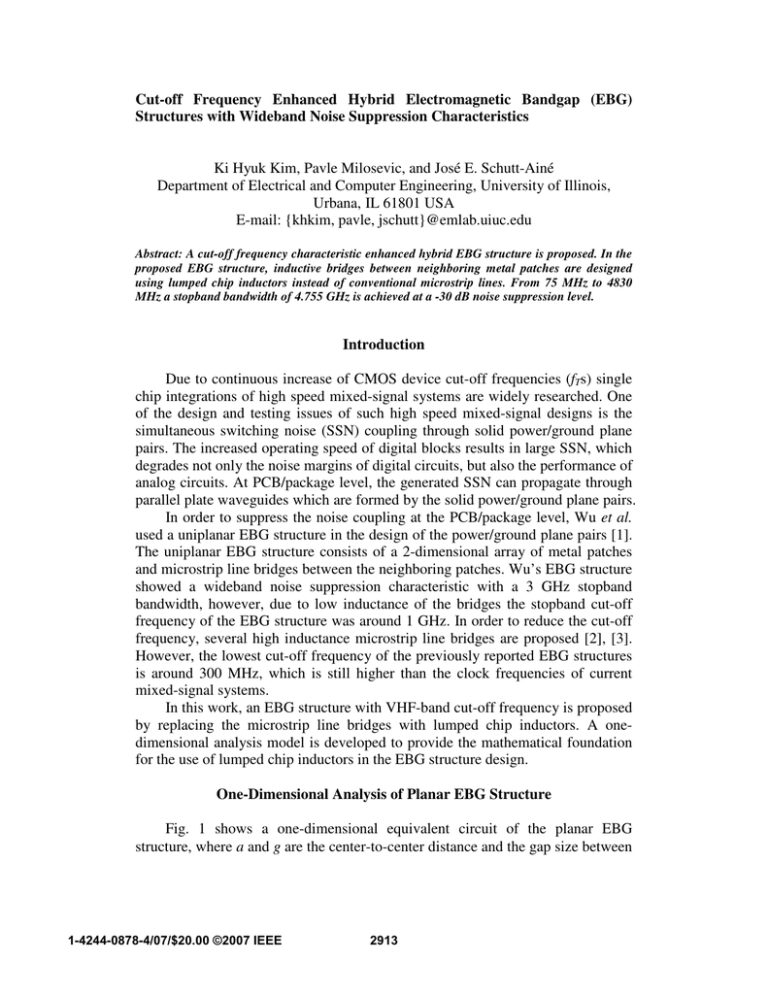

Fig. 2 (a) shows the fabricated hybrid EBG structure. In order to directly

compare the noise suppression performances, physical dimensions and port

locations of the proposed EBG structure are the same with those of reference [2],

and captioned in the figure. The thickness and the dielectric constant of the

substrate are 0.4 mm and 4.4, respectively, and Coilcraft, Inc., 0603LS-561X 560

nH chip inductors are used as the bridges instead of the microstrip lines.

(a)

(b)

y [mm]

x [mm]

(c)

Var

Eqn

12×12 array of T-models

L

L1

L=lp_2

R=

(74, 74)

Inductor

bridge

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X1

X2

X5

X8

X9

X12

X13

X16

X17

X20

X21

X24

Port 2

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X3

X4

X6

X7

X10

X11

X14

X15

X18

X19

X22

X23

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X28

X25

X29

X32

X33

X36

X37

X40

X41

X44

X45

X48

(46, 45) (74, 45)

Port 1 Port 3

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X27

X26

X30

X31

X34

X35

X38

X39

X42

X43

X46

X47

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X76

X73

X77

X80

X81

X84

X85

X88

X89

X92

X93

X96

VAR

VAR1

cp=.55339e-12

lp_2=.25133e-9

rp_2=8.6207e-4

L

L2

L=lp_2

R=

Port

P1

Num=1

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X75

X74

X78

X79

X82

X83

X86

X87

X90

X91

X94

X95

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X51

X50

X54

X55

X58

X1323

X62

X63

X66

X67

X70

X71

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X123

X122

X126

X127

X130

X131

X134

X135

X138

X139

X142

X143

Port

P3

Num=3

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X100

X97

X101

X104

X105

X108

X109

X112

X113

X116

X117

X120

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X99

X98

X102

X103

X106

X107

X110

X111

X114

X115

X118

X119

C

C87

C=cgap

C

C88

C=cgap

R

R3

R=rp_2

Port

P2

Num=2

C

C89

C=cgap

T-model

(e) 1st order LC model

(d) 12-section distributed capacitance models

C

C86

C=cgap

L

L3

L=lp_2

R=

Y1P_Eqn

Y1P1

Y[1,1]=freq*cp*tan(0.02)

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X124

X121

X125

X128

X129

X132

X133

X136

X137

X140

X141

X144

b=28.7mm

C

C85

C=cgap

L

L4

L=lp_2

R=

C

C1

C=cp

R

R2

R=rp_2

Tmodel_1cellTmodel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTmodel_1cellTm odel_1cellTm odel_1cellTmodel_1cellTmodel_1cellTmodel_1cell

X52

X49

X53

X56

X57

X60

X61

X64

X65

X68

X69

X72

g=1.3mm a=30mm

R

R1

R=rp_2

Port

P4

Num=4

R

R4

R=rp_2

C

inductor_symb_560nH

C

C

C90

X1312

C91

C92

C=cgap

C=cgap

C=cgap

C

C93

C=cgap

C

C94

C=cgap

C

C95

C=cgap

C

C96

C=cgap

Port

P1

Num=1

C

C1

C=0.16 pF

Port

P2

Num=2

L

L1

L=560 nH

Fig. 2. Schematic of Proposed EBG PDN and corresponding ADS simulation models

Fig. 2 (b) to (e) show the ADS simulation models for the patches, the gaps,

and the lumped chip inductors, respectively. The 2-dimensional array of

distributed RLCG element method [6] is used to model the patches. 12-section

distributed C models and 1st-order parallel LC models are used to model the gap

capacitances and the lumped chip inductors, respectively. Parasitic series

capacitances of the chip inductors are calculated from the self resonant

frequencies (SFRs) of the lumped chip inductors in datasheets [5].

Fig. 3 shows simulated and measured insertion loss responses of the

proposed and the reference EBG structures [2]. An Agilent E8358A PNA Series

Network Analyzer is used to measure the S-parameters, and for brevity of figure

only |S21| responses are plotted. The open circles represent the measured |S21|

response of a structure without the EBG structure, while open and solid rectangles

represent simulated and measured |S21| responses of the proposed EBG structure,

respectively. The reference EBG structure [2] is simulated using Ansoft HFSS,

and the solid circles represent simulated |S21| responses. The calculated,

simulated and measured cut-off frequencies of the proposed structure are 47.5,

49.2 and 47.2 MHz, respectively. The measured stopband bandwidth of the

proposed EBG structure at the -30 dB noise suppression level is 4755 MHz (75 –

4830 MHz), while the simulated stopband bandwidth of the reference EBG

structure is only 4325 MHz (555 – 4875 MHz).

2915

Conclusions

In this work, a hybrid EBG structure with a cut-off frequency of 47.2 MHz

and a noise suppression bandwidth of 4.755 GHz is proposed by using lumped

chip inductors instead of microstrip lines. The stopband bandwidth is enhanced by

more than 430 MHz and the enhancement can be further increased by using

higher values of chip inductors. The 1-dimensional analysis model and the ADS

circuit level simulation models are also developed for the proposed EBG structure.

The simulated and measured |S21| responses of the proposed EBG structure are in

substantial agreement with each other.

Measurement:

Solid Plane

HFSS Simulation: ref. [2] EBG

ADS Simulation: Proposed EBG

Measurement: Proposed EBG

Insertion Loss [dB]

0

-20

Stopband bandwidth

(-30 dB suppression)

-40

Enhanced

Suppression BW

-60

-80

0

1

2

3

4

5

Frequency [GHz]

Fig. 3. |S21| Insertion Loss Characteristics of the Proposed EBG Structure

References:

[1] T.-L. Wu, et al., “A novel Power Planes with Low Radiation and Broadband Suppression of

Ground Bounce Noise using Photonic Bandgap Structures,” IEEE Microw. Wireless Comp.

Lett, vol. 14, no. 7, July 2004.

[2] T.-L.Wu, et al., “A novel power plane with super-wideband elimination of ground bounce

noise on high speed circuits,” IEEE Microw. Wireless Comp. Lett., vol. 15, no. 3, pp. 174–176,

Mar. 2005.

[3] X.-H. Wang, et al., “A Novel Uniplanar Compact Photonic Bandgap Power Plane with UltraBroadband Suppression of Ground Bounce Noise,” IEEE Microw. Wireless Comp. Lett., vol.

16, no. 5, May 2006.

[4] Jinwoo Choi, “Noise Suppression and Isolation in Mixed-Signal Systems using Alternating

Impedance Electromagnetic Bandgap (AI-EBG) Structure,” Ph. D. dissertation, School of

Electrical and Computer Engineering, Georgia Institute of Technology, Dec. 2005.

[5] Coil Craft, Inc., Datasheets, [Online] Available: http://www.coilcraft.com, 2007.

[6] Larry D. Smith et al., “Power Plane SPICE Models and Simulated Performance for Materials

and Geometries,” IEEE Trans. Adv., Packag., vol. 24, pp. 277-287, Aug. 2001.

2916