Material Flow Accounting for Metals in Japan

advertisement

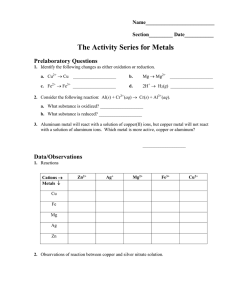

Materials Transactions, Vol. 45, No. 11 (2004) pp. 3184 to 3193 #2004 The Mining and Materials Processing Institute of Japan Material Flow Accounting for Metals in Japan Shinsuke Murakami1 , Megumi Yamanoi2; * , Tsuyoshi Adachi2 , Gento Mogi2 and Jiro Yamatomi2 1 Sustainable Material Cycles Management Section, Research Center for Material Cycles and Waste Management, National Institute of Environmental Studies, Tsukuba 305-8506, Japan 2 Department of Geosystem Engineering, Graduate School of Engineering, The University of Tokyo, Tokyo 113-8656, Japan Planning transition from conventional mass production, mass consumption, and mass disposal society to JUNKANGATA-SHAKAI (recycling-oriented society), requires detailed and accurate information concerning material flows, especially from the viewpoint of dematerialization. However, as is well known, it is nearly impossible to observe every material flow directly. Hence, the importance of Material Flow Accounting model has increased. In this study, a Material Flow Accounting model using input-output technique is developed for Japanese metal flows. Since the model uses the Input-Output framework, it can be easily integrated with the MIOT (Monetary Input-Output Table) for further simulation. However, the scope of this study is limited to static framework, because the primal goal is accuracy. The data for year 2000 is organized with the developed framework, and gives the following results. Firstly, scraps play significant roles already. Second, non-ferrous metals can be grouped into two types. The first group’s destination is mainly construction and machinery and these non-ferrous metals show the similar pattern of destination as iron. This indicates that the flows can be roughly predicted from the iron flows. The other group shows no uniform trend so that the flows are more difficult to predict than the first group. (Received March 17, 2004; Accepted August 19, 2004) Keywords: material flow analysis (MFA), substance flow analysis (SFA), material flow accounting, industrial ecology, Japanese metal flow, input-output table 1. Introduction 1.1 Background and purposes As has often been said,1) anthropogenic activities are major precursors of global environmental change. Material Flow Analysis (MFA) will reveal the relationship between human society and the entire ecosystem from the viewpoint of materials and energies considered in the analysis. These flows are taken as ‘‘Industrial Metabolism’’ and industrial ecologists have been trying to identify. The revealed relationship shows linkages between the two systems, thus clarifying potential environmental problems related to the flows. Moreover, the material and energy intensities of human economies can be derived. Material Flow Analysis always requires the considerable amount of well-organized data from Material Flow Accounting, while such data is not always available. In the case of the metals, the information exists, but lacks consistency. In this paper, we present a framework for Material Flow Accounting for metals in Japan. Then, the analysis with actual data for year 2000 will follow. The proposed framework follows the methodology called Physical Input-Output model (PIOT). The definition of the sectors similar to Monetary Input-Output Table (MIOT),2) so that the model can easily be integrated with MIOT. This will be a huge advantage when the model is expanded into dynamic one. Analysis for the flows in the year 2000 focuses mainly on the flows of ‘‘DOUMYAKU-SANGYOU’’3) and the disposal and reusing are beyond the scope for this time, thus the flows cannot be closed. However, since metal scraps are often used as the substitute inputs for the refineries and cannot be separated from the flows from virgin ores, material recycling *Graduate Student, The University of Tokyo is accounted and analyzed. The information derived from this accounting is essential for the estimation of the completely closed dynamic model. In addition, the estimation process will identify the currently unavailable though necessary data for the complete model. This is one of the main objectives of this paper. Of course, the accounted flows offer significant information to analyze. Amongst the information, the metal contents in the final goods are considered most significant. Using this information combined with the production data, the accumulation of the metal can be estimated and eventually the potential scraps in the emissions can be derived in the completely closed dynamic model. 1.2 Previous studies Although this area has drawn the increasing interests, the number of studies is still small. Many Substance Flow Analysis (SFA) can be seen for metals, though their objectives are capturing the environmental problems caused by a specific substance studied. One previous study for metals concerning Japan has been made by Kapur et al.4) The study focuses only on copper flows, and Asia is chosen as the geographical boundary. That paper is the outcome of the project called STAF,5) which intends to assess the comprehensive global material cycles. Copper and zinc were chosen as the initial objective for the project, and the paper reports initial findings for copper in the Asian region. Kapur et al. concluded as follows; Asia is net importer of copper, and the rates of both use and discards in Japan are significantly higher than those of the rest of Asian countries. Therefore, the material flow of Japan is worth to be analyzed separately. The Kapur paper is more macroscopic than this paper, though the results of these two papers can be compared. The series of papers from this group1,6–9) are also the outcomes from the projects, focusing on Europe. These papers are more Material Flow Accounting for Metals in Japan converted into E-Table for analysis. In the following section, these two tables and the accounting framework for E-Table are introduced in detail. Earth (Environment) Mining Disposal EOL Goods Ore Manufacturing Extracting Material Recycling Refinery Material Intermediate Goods Parts Reusing Products Reusing Final Products Human Society (Stocks) Fig. 1 3185 The material flows. 2.2 E-Table 2.2.1 The structure of E-Table The estimated E-Table for this paper is shown in Table 1. Since this submodel expresses the smelting processes, inputs for this table are ores and scraps. And the outputs are ‘‘Materials.’’ Originally, the EOL goods was inputs instead of scraps and outputs include parts and products via reusing. However, as repeatedly mentioned, reusing is out of scope for now. All amounts are recorded with the unit of the metals contained and following relationships must be hold. X X AEvij þ AEsij ¼ MI i ; for i ¼ 1 to m1 ð1Þ j X j AEvij þ FEvj þ EXvj IMvj ¼ CTEvj ð2Þ AEsij þ FEsj þ EXsj IMsj ¼ CTEsj ð3Þ i comprehensive and include more expanded analysis using statistical entropy analysis technique.9) The notable conclusion from the analysis is that European copper flows as a whole neither concentrates nor dissipates significantly in the region. 2. Accounting Framework 2.1 Metal material flows Figure 1 shows the metal material flows generally considered in this type of studies. However, in this study, not all flows could be included. Disposal and two types of reusing are out of focus. Mining is ignored, too. Thus, only solid lines in the figure are the flows estimated and the dotted lines are placed outside of the boundary this time. In this accounting framework, ‘‘Materials’’ basically refers the goods produced from smelters. Then, non-ferrous alloys10) are categorized as ‘‘Intermediate Goods’’, not ‘‘Materials,’’ while the metal oxides are ‘‘Materials.’’ In the metal material flows, ‘‘Materials’’ have comprehensive and reliable information so that can be utilized as a fundamental information for the overall accounting. Therefore, the flows are divided into two types, ‘‘Materials’’ extraction flows and manufacturing flows and both are expressed in separated submodels. The submodels are called E-Table and M-Table, respectively. M-Table follows the usual Input-Output table with physical units, whereas ETable is in much simpler framework. However, the simplicity of E-Table makes its estimation more difficult so that another framework is required for accounting purpose. Of course, the advantage of the Input-Output technique lies in the fact that the one model can include everything in the system. Then, excluding extraction flows seems the loss of this advantage. However, the existence of so many byproducts in the smelting flows forced the separation. SNA-style Input-Output (SNAIO) technique is an accounting framework rather than analytical, and allows to include multiple products from one activity. SNAIO can be converted into usual IO table afterwards. Then, smelting processes are once accounted with modified SNAIO technique and then X i This submodel intends to identify the balance of the sources for each material and not easy to be estimated directly. Therefore, all information available are accounted in the framework introduced in the next section, and then converted to the table shown in Table 1. 2.2.2 Estimation framework of E-Table E-Table shown in Table 1 can identify the relationship between the produced material and its source. For example, the row vector of gold metal contains values both in gold and copper ores columns, and these numbers are unknowns. Thus, another framework for accounting is developed and then converted into E-Table. The developed framework largely owes to SNAIO table. This technique has one obvious advantage over usual IO technique in accounting: this allows to contain multiple products from one industry, that is joint production. For more details of SNAIO and its analytical techniques, see Fujikawa (1999).11) Goods and industries are distinguished in SNAIO technique, whereas in usual IO technique these two are equivalent with the assumption of one activity-one products. Usual IO table consists of one square matrix of goods-goods, or industries-industries. However, SNAIO table has two rectangular matrices of goods-industries, and industries-goods. A matrix of goods-industries is called use table (U-Table) and its column vectors show which industry purchases which goods in what amount. Another matrix of industries-goods is called make table (V-Table) and its row vectors tell which industry produces which goods in what amount. It is obvious that this V-Table can contain multiple products from one industry and does not require the previous assumption. In this study, ‘‘Industries’’ in SNAIO are replaced with ‘‘Processes’’ of smelting. The proposed framework is shown in Table 2. This submodel describes smelting industry. Both natural resources and scraps are inputs from outside the system and can be treated like as primary inputs. Then, primary inputs vector of usual SNAIO is replaced by the vector of natural resources and scraps inputs. Similarly, final 3186 S. Murakami, M. Yamanoi, T. Adachi, G. Mogi and J. Yamatomi Table 1 Estimated E-Table in 2000. Inputs Scraps Materials production Total amount extracted Virgin ores AEv : m × v MI : m × 1 Parts reusing AEs2=0 0 PRU=0 Products reusing AEs3=0 0 RU=0 FEs=0 FEv : 1 × v Exports EXs : 1 × ns EXv : 1 × v Imports IMs : 1 × ns IMv : 1 × v CTEs : 1 × ns CTEv : 1 × v Outputs (i) AEs1 : m × ns Metals not extracted Total amount domestically inputted Table 2 Detailed submodel for estimation. Goods Im. R. & S. Mat. Processes Goods: n' Resource & Scraps : (v+ns) U: n' × n use table Material :m Inputs from outside Total supply Total demand 0 Intermediate goods Processes: n Final outputs 0 q: n' × 1 total demand MI: m × 1 material outputs x: n × 1 production V: n × n' make table CTEv, CTEs 1 × (v+ns) 0 qt: 1 × n' total supply 0 xt: 1 × n cost Material Flow Accounting for Metals in Japan demands vector is replaced by material production vector, MI. All numbers are accounted in the amount of metal contained and no additional values exist. U-Table contains the amount of goods used by each process, and the outputs from each process are accounted in V-Table. Only but not negligible problem left is the fact that all amounts should be captured by the amount of the metals contained, because that Material Flow Accounting is based on the universal law of mass conservation. These data is not available directly, thus should be estimated. The estimation requires the composition of all goods, however the compositions are not stable. In this study, the values from previous studies are used. Ideally, the compositions should be updated every time the table is estimated. With these compositions, the table can be filled. Then, the conversion to E-Table follows. This conversion requires one assumption concerning joint production. There are two alternative assumptions used when SNAIO is converted into usual IO table; industry technology assumption, or commodity technology assumption. A input coefficient matrix B are defined as follows. ( ) Uij B ¼ bij ¼ t ð4Þ xj Industry technology assumption is that inputs coefficients of B is stable no matter how the outputs from the industries vary. On the other hand, commodity technology assumption is that the inputs for one product is unchanged no matter which industry produced. Both assumptions seems strong. However, in the case of this study, commodity technology assumption is unacceptable. For example, the gold produced as main products from gold ore must be produced from same inputs as the gold metal as by-product from copper ore under the assumption. So, the industry technology assumption is adopted. Now, another coefficient matrix D, which is often called industry mix in SNAIO, is defined as follows. Then, the following relationship must be kept. q m ¼ B Dðq mÞ þ f Vij where D ¼ dij ¼ ðqj mj Þ ð8Þ should be held. In this estimation, MI is exogenously given to the model from some data source. Also, m is given. Thus, AEv and AEs1 matrices are only unknowns left in E-Table. From the eq. (8), 2 3 0 0 AEv; AEs1 6 7 0 ð9Þ 40 0 5 0 0 0 ¼ IMðB DðI ðI IMÞB DÞ1 ðI þ IM B DÞf^ þ f^ Þ: Using this equation, E-Table will be estimated from the accounting model of Table 2. 2.3 M-Table M-Table includes all manufacturing processes other than mining and refinery processes. Then, ‘‘Materials’’ are not allowed produced in this model. All ‘‘Materials’’ production processes, which are refining processes, are described in E-Table, and ‘‘Materials’’ are inputted into M-Table like as domestic imports. M-Table is shown in Table 3. Except for the existence of a column vector, DIM, this table is basically same as usual IO Table. And the following relationships must be held for keeping mass balance. CTm ¼ AM þ EX þ FD DIM IM X where AMi ¼ AM i ð10Þ j 2.4 Metal material contained Identifying the amount of ‘‘Materials’’ contained in each product is one analytical goal of this study. The methodology is introduced here. The material balance of the table introduced in the previous section can be rewritten as the following eq. (11). If E-Table contains the information concerning reusing, DIM2 vector is not zero vector. However, this is zero in this study. where 0 ð5Þ MI 1 B C DIM1 ¼ @ 0 A ð6Þ Using this IM matrix, the eq. (5) is q m ¼ ðI ðI IMÞB DÞ1 ðI þ IM B DÞf: m ¼ IMðB DðI ðI IMÞB DÞ1 ðI þ IM B DÞf þ fÞ ¼ AM þ EX þ FD DIM1 DIM2 IM Then, since any processes in this submodel does not produce any natural resources nor scraps, m ¼ ðB Dðq mÞ þ fÞ IMðB Dðq mÞ þ fÞ 2 3 I 0 0 6 7 where IM ¼ 4 0 0 0 5: 0 0 0 Thus, CTm ¼ AM þ EX þ FD DIM IM m ¼ ½CTEv; CTEs; 0 . . . . . . ; 0: 2 3 0 6 7 f¼4 0 5 MI 3187 ð7Þ AMi ¼ X 0 and 0 1 B C DIM2 ¼ @ PRU A ¼ 0 0 ð11Þ RU AM i j n . o Am ¼ Amij ¼ AM ij CTmtj ‘‘Import,’’ ‘‘Export,’’ and ‘‘Final Demand’’ can be treated as exogenous. However, ‘‘MI’’ should be able to be derived endogenously. Let F1 denote everything other than intermediate demands and MI. MMI is the matrix, which has same the dimension as AM. Since no goods belonging to ‘‘Material’’ should be produced inside ‘‘Manufacturing Table’’, then the following 3188 S. Murakami, M. Yamanoi, T. Adachi, G. Mogi and J. Yamatomi Table 3 M-Table. N×N N×1 ð12Þ 0 Using this equation, eq. (11) will be CTm ¼ AM þ F1 MMIðAM þ F1Þ ¼ Am CTm þ F1 MMIðAm CTm þ F1Þ ð13Þ 1 ¼ ½I ðI MMIÞAm ðI MMIÞF1 With this eq. (13), we can derive CTm from F1. Then, substituting this into eq. (12), DIM can be derived. DIM1 ¼ MMIðAmf½I ðI MMIÞAm1 ðI MMIÞF1g þ F1Þ ð14Þ With this eq. (14), the repercussion effect from the increase in the final demand sector onto the material inputs can be derived. Assuming one unit increase in F1 of a final product, MI will be derived. This is the one of the most important characteristics of this model. The meaning of the derived MI for one unit of F1 of one specific final product is the metal contained in one unit of the final product. Hence, substituting an identity matrix into F1 of eq. (14), MC matrix will be derived. This MC matrix has same dimension as MMI or Am. MC ¼ MMIðAmf½I ðI MMIÞAm1 ðI MMIÞIg þ IÞ 2 3 2 3 I MCI MCF MC2 6 7 6 7 MC ¼ 4 0 0 0 5¼4 0 5 0 0 0 0 EX FD CTm N×1 N×1 N×1 N×1 RU DIM1 ¼ MMIðAM þ F1Þ ¼ MMIðAm CTm þ F1Þ 0 Control totals: Domestic production DIM= PRU relationship must be hold. 0 Domestic final demand 0 where F1 ¼ FD þ EX IM DIM2 0 1 I 0 0 B C MMI ¼ @ 0 0 0 A IMP MI 0 Final goods Exports AM= Intermediate goods Domestic inputs: from E−Table Final goods 0 Imports Inputs (i) Materials Intermediate goods Materials Outputs (j) ð15Þ This MC2 matrix should have same dimension as AEs1 in the Extraction table. With this calculation, the metal materials contained in per unit goods are derived in the form of the matrix, MC2. In order to make further analyses, another conversion matrix, MCM (Metal Contained in Material) is required. This matrix has the dimension of ‘‘the number of the metals studied the number of materials’’. This MCM matrix will be known by the materials definitions. For most materials studied, their compositions are defined by industrial standards, like as JIS (Japan Industrial Standard).12) The composition may vary a little. In this study, the composition defined by JIS is used for this MCM matrix and also as the estimation foundation in E-Table. These MC and MCM matrix will be used in order to convert the goods flows to materials, or metal flows. If one unit of automobile is produced, multiplying the automobile column vector of MC matrix with one, provides the amount of each material used. Then, multiplying these amounts of materials with MCM matrix, we will know how much metals contained in one unit of automobile. 2.5 Accounting procedures The outline of the accounting is follows. Firstly, data for natural resources and scraps inputted to E-Table as inputs is collected. Also, the production of the materials are captured from both governmental and private statistics. Since the compositions for the materials are available from industrial standards, like JIS (Japan Industrial Standards), the metals contained in the materials can be estimated. With these information, E-Table can be estimated. Next, the production of materials, MI, are inserted in MTable. It will be distributed to each direction. Only thing worth to emphasize here is the following; since this model is intended to describe the material transformations, the change of ownership is not the issue of concern. The estimation of M-Table sometimes utilizes information of MIOT, however, the goods and services must be strictly distinguished. For example, transportation sector purchases automobiles. Of Material Flow Accounting for Metals in Japan course, automobiles cannot be transformed into the goods named ‘‘transportation,’’ but they are simply purchased as the transporter. Hence, this difference is of vital importance, and this is the reason why PIOT cannot be estimated automatically from MIOT. All values must be accounted in the amount of the metal contained. However, considering application later, the amounts had better be accounted not only in the metal amount but also in the appropriate unit. For example, let’s assume the followings; electric wires are demanded 100 meters domestically, and 20 meters for exporting. However, 30 meters of cables are imported. On the other hand, preceding estimation says 2700 kilograms of copper and 900 kilograms of aluminum are used in the production of electric wires. Then, domestic production of the electric wires are expressed as 3600 kilograms of metals contained. Then, the amount of imports should be expressed as 1200 kilograms of metals contained. In this case, 3600 kilograms of metal is accounted as the domestic production of the ‘‘electric wire.’’ However, if 100 meters are also recorded, this plays huge role in further expansion of the model, like as dynamic expansion. In the estimation, inconsistency might occur, that the summation of the rows and columns are not equivalent, and of course it is not acceptable. Then, in order to make the matrix balanced, RAS13) methodology is applied as necessary. In the next chapter, the Japanese metal material flows for year 2000 will be accounted and analyzed with this framework. The primal purpose is analyzing the metal material flows for year 2000 in Japan, but deriving accurate MC matrix is the another significant purpose. 3. Analysis of the Flows for Year 2000 3.1 Findings from E-Table From this section, the Japanese metal material flows for year 2000 will be presented and analyzed. Firstly, the findings from E-Table is introduced. Nineteen metals are chosen for the analysis, mainly because of the availability of data. However, the higher data availability can be considered to reflect its importance in the economy and thus appropriate standard for the choice. Gold, silver, copper, lead, zinc, aluminum, nickel, chromium, cobalt, molybdenum, manganese, iron, magnesium tungsten, antimony, platinum, palladium, titanium, and tin are chosen for this study. And the amount of these metals contained in the flows are estimated. Even though some data concerning reusing are not available and excluded from the estimation, data for scraps collected for recycling is available, hence the table was successfully estimated. 23 types virgin resources and 13 scraps are input sources of this table, and 60 types of materials are outputs. In principle, the goods called ‘‘Material’’ in this model are not alloys and should consist of single metal. Though, pig irons and ferroalloys are exceptions. In addition, some scraps directly appears as materials and they are sometimes alloys. So many joint productions are found in the E-Table. Especially, copper, lead, and zinc concentrates are significant 3189 sources for Japanese smelting. Originally, smelting industry is highly horizontally integrated. Thus, the residues from a smelting process is often inputted to another metal’s refining process. As for copper, lead, and zinc, the number of materials, which depend more than 20 percents of their sources on these three concentrates, are 5, 7, and 3 respectively. For example, lead and copper smelting processes are often related with silver refining process. From the residues of silver electro refining, gold, and the platinum groups metals are recovered. Then, these materials heavily depend on copper and lead concentrates. Japan has a gold mine, HISHIKARI-mine, which produces high grade ores. However, even the ores mined in HISHIKARI are refined in the company’s copper smelting process. These fact supports the idea that E-Table should be able to describe joint productions. 3.2 Metals in each product As mentioned in the previous sector, ‘‘Materials’’ were divided into 60 types, although the number of the metals concerned is 19. Then, ‘‘Intermediate Goods,’’ which sometimes go directly to final consumption, were divided into 66. The number of ‘‘Final Goods’’ are 52. Unfortunately, data were far from abundant and statistics from different sources were utilized. In addition, the interview survey played significant role in data acquisition. Still, as mentioned before, the data for reuse was not available this time. After the data collected as much as possible, each component of this table were adjusted to make the matrix balanced. With the methodology introduced in 2.4, the ratio of metal materials included in each goods, MC is estimated. Multiplying the composition of each material, MCM, this MC matrix can be converted into the matrix of metal contained, MMC. The result is shown in Fig. 2. Obviously, almost all final goods depend heavily on iron. ‘‘Rechargeable Batteries’’ is a rare exception, in which predominates other metals. Titanium appearing in some sector is mainly pigments. Most of the titanium used as alloys is exported and not much left in Japan. Construction and automobile industries use about 60 percent of domestically used non-ferrous metals in weight. 45 percent of the whole metal including iron goes to constructions. Zinc, nickel and chromium used in construction industry are used as ingredients of steels. 3.3 Destinations for each metal Although Fig. 2 shows a lot of implications, the detailed characteristics are hardly seen, as base metals occupy the huge amount in weight. Thus, from here, the each metal’s destination is analyzed respectively. The destinations for each metal are shown in the Fig. 3. Gold: Large part of gold goes to various manufacturing goods through electric devices. Also, metal products is another huge destination. Very roughly speaking, gold is used as points for electric devices, or simply kept as metal. Silver: Large part of silver goes to chemical industry. These silver is used as ‘‘Nitrate for Sensitizer’’ mainly for photographs. Tungsten: Tungsten is used as the ingredients of ferro- 3190 S. Murakami, M. Yamanoi, T. Adachi, G. Mogi and J. Yamatomi Fig. 2 Metal contained in each product. tungsten. However, superalloys are another destination and it will be used as the material for the machineries. Platinum: Platinum goes to chemicals or ‘‘Other machineries.’’ The former are as catalysts, and the latter are the parts for electric devices. Palladium: The destination of palladium varies. The fact that platinum and palladium rarely go to construction makes these two metals distinguishable from base metals. Titanium: One strong characteristics of titanium is the amount used for papers and publishing. Even though titanium is often used as alloys, they are rarely left inside Japan. The large part of titanium destination are pigments. Tin: The reason why large part of tin is consumed for electric devices is that the tin is a major component of solder. Other than solder, tin is used as the ingredients of so many alloys so that the destination varies. Antimony: Antimony shows completely different trends. This is mainly used for chemicals, though its final destination varies. Lead: Huge part of lead is consumed as rechargeable batteries and the batteries are used for automobiles. Copper: Copper’s destinations varies. Copper is used as brass or electric wire. Main difference from other non-ferrous base metals is that the large part of copper is used for constructions. Aluminum and Manganese: Comparing other base metals, the ratio for automobiles is slightly larger than other metals, in the case of aluminum. Since large part of manganese is used as the ingredients for aluminum alloys, its destination is similar to that of aluminum. Zinc: Zinc is consumed as castings. However, huge part of zinc is used as the ingredients of alloys like as brass, or aluminum. Also zinc plating on steel is popular. Considering these applications, the fact that its destinations varies seems rational. Iron, Cobalt, Magnesium, Nickel, Molybdenum, and Chromium: Large part of these non-ferrous metals are used as the ingredients of ferroalloys. Thus, the destinations of these metals show similar trend as iron. 3.4 Total material flow balance As usual in material flow analysis, the total metal material flow is analyzed. The results are shown in Fig. 4. As expected, Japan is obviously a resources importing country. It heavily depends on imports for its virgin metal resources, which occupies about 70 percent of its resources. Domestically produced ore is only 0.15 percent of its total resources. On the other hand, scrap fills the remaining 30 Material Flow Accounting for Metals in Japan 3191 Fig. 3 Destinations for each metal. Imported Resource 85,199,246 Imported Material 6,051,533 Imported Intermed. Goods 5,878,594 Imported Final Products 5,011,793 Domestic Final Demand 90,259,489 Domestic Resources 176,757 Recyclable Scraps Domestically Consumed 37,562,600 Fig. 4 Material Export 980,565 Intermed. Goods Export 31,993,045 Final Products Export 16,647,424 Aggregated material flows [tons]. percent. Aluminum and iron (including both steel and pig irons) are large part of this. However, other scraps are not small. Metals contained in ferroalloys can be considered recovered as part of steel scraps. In later stages of the flows, still, ‘‘Materials’’ import is larger than its export. However, exports exceed imports for the stage of intermediate goods and final goods. As is usually considered, from the viewpoint of metal material consumption, Japan is a resources importing and products exporting country. Material flow balance for each metal is shown in Fig. 5. Left hand side of this bar graph shows the ratio of metal inputs into Japan, and the right hand side shows the output. The metals are placed in order of the amount of domestic virgin source plus scraps. As for inputs, copper, zinc, iron, lead, manganese, nickel, silver, gold, tungsten, antimony and titanium are supplied as virgin resources imported. Aluminum, chromium, molybdenum, tin, palladium, cobalt, platinum and magnesium are supplied through materials imported. For all metals, imports as ‘‘Intermediate Goods’’ and ‘‘Final Goods’’ are very small. Another thing should be mentioned here is that the domestic productions of gold and silver are largely as byproducts from copper smelting. Even though this cannot be 3192 S. Murakami, M. Yamanoi, T. Adachi, G. Mogi and J. Yamatomi Fig. 5 Input output balance for each metal. read from these graphics, this is an important information for further simulation analysis. As for outputs, though Japan is products exporting country, still main destination for almost all metals are domestic final demand. Only exception here is cobalt. Cobalt is used as parts for rechargeable batteries and Japan is a large exporting country for these batteries. Only palladium, platinum, and titanium are exported as materials in significant amount. Other than these three, metals are exported mainly as intermediate goods or final goods. 4. Concluding Remarks In this paper, the framework for the metal material flow accounting and some analytical technique was proposed, and then the flows for year 2000 is accounted utilizing the information mainly from existing statistics and analyzed. The proposed framework consists of two submodels, called ETable and M-Table, respectively. With the introduction of E- Table, which is specified for the smelting and refining processes, joint productions in smelting processes can be well described and also many existing analytical methodology for Input - Output analysis can be utilized with some adjustment. The well known fact that Japan is resources importing and products exporting country is confirmed from the viewpoint of metal material flow. This result is consistent with Kapur et al.4) The importance of domestic scraps as source is confirmed, too. Since non-ferrous alloys and steels dominate the flow in weight, the destinations for the metals, which used as ingredients of the alloys and steels, are similar to those for iron and other non-ferrous base metals. Data for reusing cannot be collected with sufficient quality for the accounting. Also, the exports of secondhand goods cannot be captured. Even the model is expanded into dynamic and closed, the lack of data for these two is unacceptable. If either of these is acquired, another can be estimated as difference. Material Flow Accounting for Metals in Japan The proposed framework can be easily expanded into dynamic, and connected with MIOT. With the expansion, the emission from the human society can be modeled and thus further analysis will be made possible. However, this is out of scope of this paper, and left untouched as future work. The primal purpose of the proposed framework is to account the domestic metal material flows in detail. Of course, the framework itself can be applied to other materials. However, the definition of sectors depends on the target materials. As long as possible, the flows should be traced over the boundaries. In order to make international studies, the flows of other nations should be accounted with the same framework and connected so that the more detailed analysis will be possible. This remains as the future work. 4) 5) 6) 7) 8) 9) 10) 11) REFERENCES 1) T. E. Graedel: Eco. Econ. 42 (2002) 5–7. 2) Known as SANGYO RENKANHYO in Japanese. 3) ‘‘DOUMYAKU’’ is the Japanese word meaning ‘‘artery’’ and 12) 13) 3193 ‘‘SANGYO’’ means industry. This word refers traditional manufacturing industries and the antonym for ‘‘JOUMYAKU (vein)-SANGYO,’’ which refers industries concerning disposal, recycling, and reusing. This metaphor comes from the analogy between material cycles and blood circulatory systems. A. Kapur, T. Bertram, S. Spatari, K. Fuse and T. E. Graedel: J. Mater. Cycles Waste Manag. 5 (2003) 143–156. Stocks and Flow Project at the Center for Industrial Ecology, Yale University. T. E. Graedel, M. Bertram, K. Fuse, R. B. Gordon, R. Lifset, H. Rechberger and S. Spatari: Eco. Econ. 42 (2002) 9–26. S. Spatari, M. Bertram, K. Fuse, T. E. Graedel and H. Rechberger: Eco. Econ. 42 (2002) 27–42. M. Bertram, T. E. Graedel, H. Rechberger and S. Spatari: Eco. Econ. 42 (2002) 43–57. H. Rechberger and T. E. Graedel: Eco. Econ. 42 (2002) 59–72. Ferro alloys are categorized as ‘‘Materials,’’ since pig iron is ‘‘Material’’ and exists in the same stage of the steel making cycle. K. Fujikawa: Input-Output Analysis of Global Economy, (Sohbun-Sha, Tokyo, 1999). Japan Industrial Standards are defined by Japan Standard Association. As for RAS method, see M. Kuroda, K. Shinpo, K. Nomura and N. Kobayashi: KEO Database, (Keio University Economic Observatory, 1996) pp. 95–99.