Siemens TIASTAR MCC

advertisement

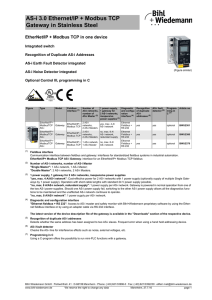

Automation and Drives Siemens TIASTAR MCC Automation and Drives Agenda TIASTAR Evolution Siemens’ MCC Offering TIASTAR Features TIASTAR Plug-in Units TIASTAR Unique Features Options and Accessories Smart MCC Automation and Drives The TIASTAR Evolution System/ 89 Model 95 Plus + TIASTAR = Automation and Drives TIASTAR (tie-star) TIASTAR defines the new MCC as a customer focused product consistent with Siemens’ emphasis on Totally Integrated Automation. Automation and Drives TIASTAR Features Horizontal Wireway: •Available bus ratings: 600A to 2000A •Bus Bracing: 42kA to 100kA •Single piece bus support •Tin or Silver plated Copper (No Aluminum) •Clear Lexan horizontal wireway barrier •Isolates bus from horizontal wireway •Easy visual inspection of bus •Thermal scan without removing components •Strong and flexible barrier that is easy to remove •Max. Temp. rise of 50°C over 40°C ambient Automation and Drives TIASTAR Features Structure Configurations: •Full side sheet and divider sheet structure design •All sections are isolated •Vertical wireway painted white •Front only - 15” or 20” deep •Back-to-back – 21” deep •72” to 144” of total unit space Automation and Drives TIASTAR Unique Features Completely isolated and insulated vertical bus •Isolated - prevents accidental contact •Insulated - sandwiched insulation prevents arcing faults from propagating Automation and Drives TIASTAR Motor Control Centre Structures Feature: Back of vertical wireway painted white Benefit: Provides good visibility on wires routed through the wireway Automation and Drives Auto Shutters Side View High degree of safety Front View Automation and Drives TIASTAR Motor Control Centre Structures Feature: Hinged doors over top horizontal wireway Benefit: Provides fast and convenient access to the top horizontal wireway. Some mcc manufacturers supply bolt down covers Automation and Drives TIASTAR Plug-in Units •Plug-in units through size 5 FVNR breaker and fusible type •Swing out terminal block panel •White interior Automation and Drives TIASTAR Plug-in Units Dual location pilot device panel •Facilitates easy removal of unit •The complete unit may be bench tested •Clear access to unit parts while door mounted Automation and Drives TIASTAR Plug-in Units Racking Lever and Handle •Unit stabs are engaged and disengaged with minimum effort •Racking Lever insures the plugin unit is fully inserted into the unit •Easy insertion and withdrawal •Handle facilitates easy removal and installation of unit Automation and Drives TIASTAR Plug-in Units Test Position / Positive Stop •Unit can be partially withdrawn in order to disconnect stabs from vertical bus •At the positive stop the unit can be locked in place with two padlocks •Positive Stop also prevents the unit from falling out of the structure during removal Automation and Drives TIASTAR Plug-in Units Positive Unit Ground •Unit is grounded at all times while in the structure, even in test position Automation and Drives TIASTAR Plug-in Units Feature: Swing plate mounted terminals Benefit: Terminals are mounted towards the front of the unit for easy access. Swing plate allows terminals to be pivoted into the vertical wireway for wiring and test. Automation and Drives TIASTAR Plug-in Units Feature: Unit operating handle Benefit: Long throw on handle clearly indicates that the disconnect device is closed (ON). Handle clearly indicates when breaker has tripped. Handle clearly indicates when in open (off) position. Automation and Drives TIASTAR Options & Accessories Siemens Solid State Reduced Voltage Starters Siemens Innova Starters NEMA Design Automation and Drives TIASTAR Options & Accessories Siemens ESP 100 Electronic Overload Relays • • • • NEMA Class 10, 20 & 30 Trip Curves Phase loss protection - Trip within 3 seconds +- 2% Repeat Trip accuracy FLA dial adjustment • Manual and Self Reset Versions Automation and Drives “Smart” Motor Control Centre Automation and Drives Communication Solution ASI Cable Profibus Motors, Pumps, Etc Electronic Sensors Automation and Drives Communication Hierarchy Protocols define technical features and functions of the network WAN Enterprise Office Ethernet Data transfer rate AS-I 8 bit max transfer rate Industrial Ethernet Profibus 244 bytes PROFIBUS MCC capability ASAS-I Bus OS Clients, Web Clients, Data Analysis, etc. Controllers, OS Servers, Engineering Servers, Batch & Recipe Managers, etc. Transmitters, Positioners, Distributed I/O, PLC, Vision Systems, Weigh Scales, etc. Sensors, Actuators, Pushbuttons, Solenoid Valves, Contactors, Soft Start MC, Signal Towers, etc. Automation and Drives AS-i Principle of Operation •A single Master system •maximum 62 slaves per master •Constant message lengths •5ms scan time •Unshielded two-wire cable •data transmission and power distribution •max cable length - 100m without repeater - 300m with repeaters Automation and Drives Profibus-DP Principle of Operation •Utilizes token passing principle with subordinate master/slave •Maximum stations - 126 •Shielded, two-wire cable or fiber-optic cable •max length electrical cable 9.6 Km •max length optic cable 23 Km •Supported by approximately 1200 vendors worldwide Automation and Drives Today’s Conventional Wiring Complex Wiring Limited Flexibility Difficult Troubleshooting Excess space Remote I/O PLC Automation and Drives “Smart” MCC Options Three options available, depending on application •AS-I •Profibus-DP •Combination of Both Automation and Drives AS-i in an MCC An AS-i master and power supply module are installed in MCC •An AS-i slave is installed in each unit •No additional unit space required •Simple twisted pair and pull apart terminals •Facilitates easy removal of buckets PLC Automation and Drives AS-I and PROFIBUS Solution PROFIBUS-DP Connection Offers the most flexibility. DP-ASI Link AS-I Slimline Added protection using SIMOCODE-DP as O/L protection in combination Two Wire AS-I Connection with Profibus communication DP-ASI link allows total communication on one complete system AS-I Slimline VFD with PROFIBUS AS-I Slimline SIMOCODE-DP AS-I Slimline AS-I Slimline AS-I Slimline AS-I Slimline AS-I Slimline AS-I Slimline AS-I Slimline SIMOCODE-DP SIMOCODE-DP AS-I Slimline SIMOCODE-DP AS-I Slimline AS-I Slimline AS-I Slimline AS-I Slimline AS-I Slimline Automation and Drives AS-i Components Slim Line Module •22.5 mm width 4I/O •45 mm width 8I/O •I/O located in individual mcc units •Minimum unit space •All I/O connected with 2 wires •Simple troubleshooting •Easily interfaced with external AS-I devices •Easily interfaced with higher lever PROFIBUS-DP Networks Automation and Drives “Smart MCC” Actuator Sensor Interface Automation and Drives Profibus-DP in an MCC •A communications capable slave in each unit •No additional space required •Standard Profibus cable is daisy chained through the MCC •Starter unit removal facilitated by detachable connector Automation and Drives SIMOCODE - DP Advanced motor protection (overload, current assemmetry, jam, loss of load, ground fault and PTC thermister input) Communication of statistical data via PROFIBUS-DP (motor current in amps and percent, number of starts, running hours, current at last trip, etc.) Onboard I/O (Four digital input and four digital output points on base module expandable to 12 input and eight output) Self contained logic functions (timers, counters, truth tables, etc.) Multiple operating voltages (24VDC, 115VAC and 230VAC) Remote programming via PROFIBUS-DP Network Automation and Drives SIMOCODE-DP Automation and Drives Diagnosis, Detailed information for operation and service Current data during operation, e.g. : Current in amps and percent On, Off,Forward, Reverse, Fast, Slow, Run time Switch-status of the motor derived from the current Manual / automatic operation Cooling time Detection of incipient problems, e.g. : Overload warning Current limit exceeded Asymmetry of phases Thermistor warning Short-circuit in thermistor wire Automation and Drives Diagnosis, Detailed information for operation and service Fast diagnostics in the event of errors (up to 30 single messages) Tripping/warning because: Overload Thermistor motor protection Stall protection Current limit exceeded Ground fault Phase failure Preventive maintenance based on statistical data, e.g. : Number of start-ups Number of times overloads have been triggered Operating hours Automation and Drives SIMOCODE-DP Areas of application Chemical, oil and gas industry incl. offshore / onshore-systems Paper, cement Mining industry / mine operations Water and waste water industry Food industry Power stations Automation and Drives Basic Unit 3UF50 Survey of Design Current range Width 0.25/1.25...100 A 50...205 A 70 mm 120 mm push-through technique 125...500 A 145 mm flat-bar terminal 200...820 A 230 mm Automation and Drives Profibus-DP Components CB15 Profibus-DP adapter for VFD’s •Access to internal parameter set •Allows high speed cyclical communication •125 inverters maximum •Easy installation Automation and Drives Both AS-i and Profibus-DP in an MCC •AS-I or Profibus-DP slave selection based on individual unit application •Highest degree of customization •Cost effective •Only relevant information transfer Automation and Drives Highlights of Benefits •More efficient use of space •Simple daisy chained wiring •Economical communication capability •Built in diagnostics •Flexible expandability •Reduced startup time Automation and Drives SMART MCC Project List Circuit Foil America (CFA) Noranda White Rose Dofasco Budweiser Tidewater Marine Arizona Chemical Manufacturing Mining Oil & Gas Steel Mill Food & Beverage Oil & Gas Chemical