Spot Welding Machine SF - WAHLENMEIER SCHWEISSTECHNIK

advertisement

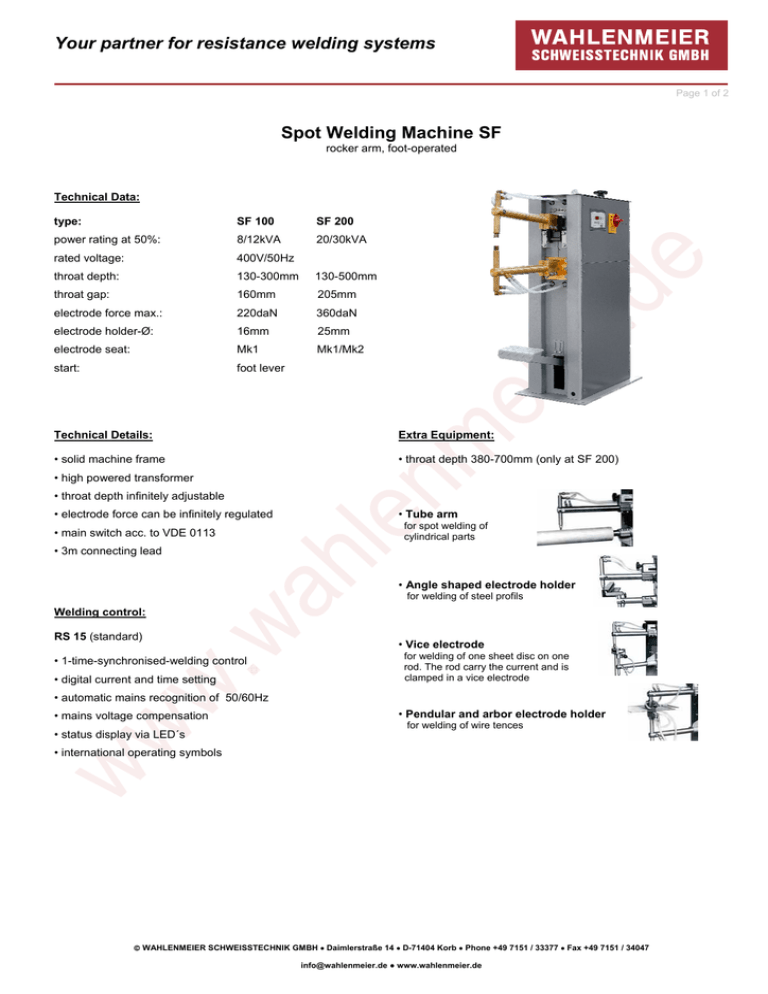

Your partner for resistance welding systems Page 1 of 2 Spot Welding Machine SF rocker arm, foot-operated Technical Data: type: SF 100 SF 200 power rating at 50%: 8/12kVA 20/30kVA rated voltage: 400V/50Hz throat depth: 130-300mm 130-500mm throat gap: 160mm 205mm electrode force max.: 220daN 360daN electrode holder-Ø: 16mm 25mm electrode seat: Mk1 Mk1/Mk2 start: foot lever Technical Details: Extra Equipment: • solid machine frame • throat depth 380-700mm (only at SF 200) • high powered transformer • throat depth infinitely adjustable • electrode force can be infinitely regulated • main switch acc. to VDE 0113 • Tube arm for spot welding of cylindrical parts • 3m connecting lead • Angle shaped electrode holder for welding of steel profils Welding control: RS 15 (standard) • 1-time-synchronised-welding control • digital current and time setting • Vice electrode for welding of one sheet disc on one rod. The rod carry the current and is clamped in a vice electrode • automatic mains recognition of 50/60Hz • mains voltage compensation • status display via LED´s • Pendular and arbor electrode holder for welding of wire tences • international operating symbols © WAHLENMEIER SCHWEISSTECHNIK GMBH • Daimlerstraße 14 • D-71404 Korb • Phone +49 7151 / 33377 • Fax +49 7151 / 34047 info@wahlenmeier.de ● www.wahlenmeier.de Your partner for resistance welding systems Page 2 of 2 Spot Welding Machine SF 102/104 + SF 202/204 technical data acc. to DIN 44753 / ISO 669 Type Article-no. Throat depth Machine power Machine voltage Mains connection Secondary current mm kVA kVA kVA kVA V Power rating (50%) Continuous output Maximum short-circuit power Maximum welding power Secondary idling voltage Number of regulation Stepps Rated primary voltage Rated frequency Supply power Fusing (carrier) Wire range (cable length < 15m) Rated operating current Permanent current Short-circuit-current Highest welding current Permit. Duty cycle at highest weld cur. Spot mounting Cooling water Machine measurements Power stage Welding values Electrode stroke max. Electrode force max. Throat gap Electrode arm-Ø Electrode holder-Ø Spot electrode seat Pipe connection in / out Operating pressure max. Entry temperature Consumption at max. loading Width x depth x height Weight Thyristor power stage Steel sheet (C-content ≤ 0,2%) CrNi sheet Round steel-Ø (C-content ≤ 0,2%) V Hz kVA A mm² kA kA kA kA % mm daN mm mm mm bar °C l/min mm kg mm mm mm SF 102 11-101-102 130-300 8 5,65 22,7 18,2 2,6 0 400 50/60 13,65 63/25 2,5 1,75 1,24 9,1 7,3 2,88 50 220 160 32 16 Mk1 NG 8 / G ¼“ 5 18 4 360 x 785 1150 115 RS_15_LS 1,5+1,5 0,75+0,75 max. 6+6 SF 104 11-101-104 12 8,48 36 28,8 3,2 21,6 63/25 2,5 3,79 2,68 11,2 8,9 9,07 122 3+3 0,75+0,75 max. 8+8 SF 202 11-101-130 130-500 20 14,1 SF 204 11-101-150 30 21,2 3,7 5,2 30 63/25 6 5,4 3,8 15 12 10 50 360 205 45 25 Mk1/Mk2 NG 8 / G ¼“ 5 18 4 430 x 1190 x 1260 180 RS_15_LS 4+4 1+1 max. 12+12 55,2 63/63 10 5,8 4,1 20 16 6,5 196 5+5 1+1 max. 17+17 Technical alterations reserved. The table contents refer to standard models. Water recooling units: Air-Water Recooler cooling to no more than 5-8°C above the ambient temperatures Cooling-Water Recooler with a fully-hermetic motor compressor and electronic thermostat with LCD display Type Article-no. LWK 17 40-186-017 Type Article-no. IK-V 07/B 40-186-072 Cooling power Rated voltage Pump power Water tank capacity 2kW 230V/50Hz 0,25kW 10l Cooling power Rated voltage Pump power Water tank capacity 0,9kW 230V/50Hz 0,25kW 6l © WAHLENMEIER SCHWEISSTECHNIK GMBH • Daimlerstraße 14 • D-71404 Korb • Telefon +49 (0) 7151 / 33377 • Telefax +49 (0) 7151 / 34047 info@wahlenmeier.de ● www.wahlenmeier.de