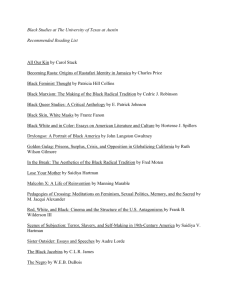

FRANTZ Manufacturing Launches GENII Semi-Precision 1.9

advertisement

FRANTZ Manufacturing Launches GENII® Semi-Precision 1.9” Conveyor Bearing to replace Commercial Unground Series (Sterling, Illinois, USA, October 16, 2012) FRANTZ Manufacturing Company, the respected name in Made in USA rolling components for the material handling industry, announces the introduction of its new 1.9” 16g GENII® 1805 Semi-Precision series conveyor bearing providing increased function at pricing equal to its industry workhorse model, the Commercial Unground 1005 bearing. Inspired by European designs over a decade ago, FRANTZ developed, tested, and introduced a Semi-Precision core bearing dimensionally equivalent to the widely used 6002 ABEC-1 core precision bearing at significantly lower cost. The FRANTZ SemiPrecision core bearing has been used with higher end conveyor bearings and field proven with sales exceeding 17 million units. The core bearing is seeded with genuine FRANTZ Sterling® steel balls manufactured in Sterling, Illinois to strict automotive quality standards. FRANTZ is pleased to introduce this technology to the traditional commercial bearing market. New GENII® 1805 Semi-Precision bearings add superior value compared to Commercial Unground bearings on three dimensions. 1) Noise reduction – 8x quieter, 2) Load rating – 2x heavier, and 3) Speed rating – 3.75x faster. In addition, FRANTZ unique stamped grooved race technology on oiled GENII® 1805 bearings provides a 25% lower starting torque. This feature reduces system costs by; 1) lower conveyor angles on gravity applications and 2) improved energy efficiency and reduced motor capacity on powered applications. In addition, bench testing of the greased GENII® 1805 Semi-Precision bearings lubed with specially formulated FRANTZ 14 grease showed a starting torque 15% lower than comparable ABEC-1 Precision bearings using BEACON™ premium lithium grease. Form and fit of the new GENII ®1805’s are identical to the 1005’s. Customers can easily convert to the GENII® 1805 bearings without any modifications to their shop floor roller manufacturing operations. Several popular bore sizes are available. #### FRANTZ Manufacturing Company’s Bearing Division and ISO/TS-16949:2009 certified Sterling® Steel Ball Division have provided high quality, specialty conveyor solutions for the material handling industry and steel ball solutions for the automotive industry for over 100 years. Based in Sterling, Illinois, USA, since 1909, FRANTZ utilizes a strong combination of domestic manufacturing, effective critical sourcing solutions, and lean production methods to provide industry recognized highest quality products. Additionally, FRANTZ has provided superb category management with a remarkable on time delivery performance in less than container lot sizes, effectively meeting customer’s lean production needs and Return on Investment requirements.