PI Manual Logger

advertisement

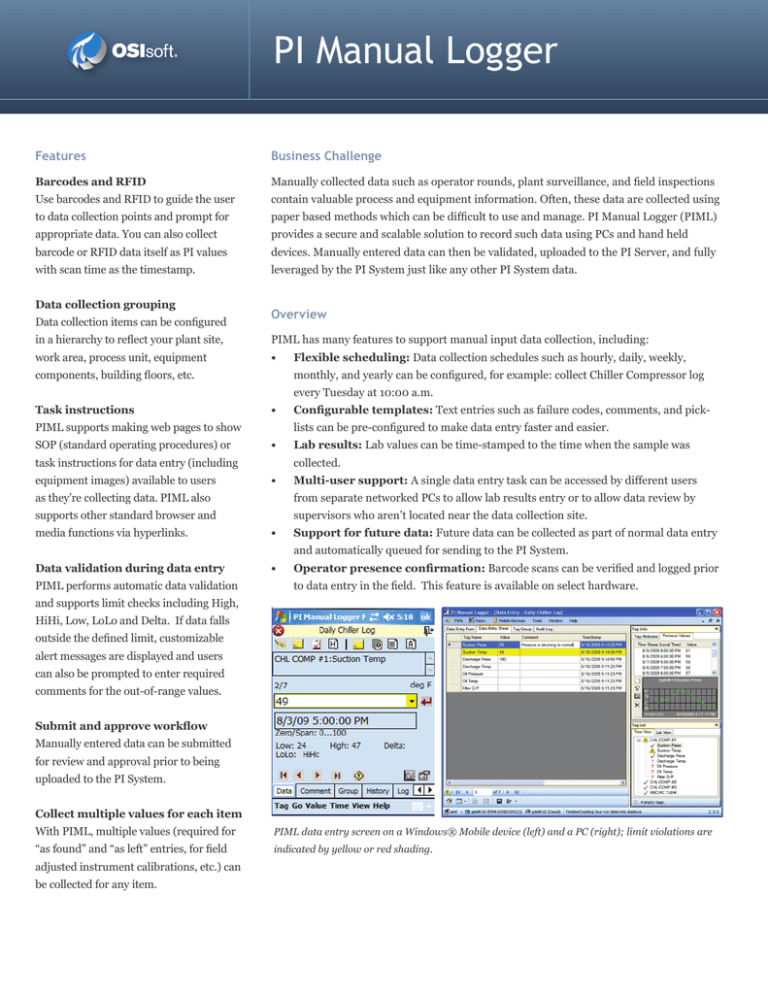

PI Manual Logger Features Business Challenge Barcodes and RFID Manually collected data such as operator rounds, plant surveillance, and field inspections Use barcodes and RFID to guide the user contain valuable process and equipment information. Often, these data are collected using to data collection points and prompt for paper based methods which can be difficult to use and manage. PI Manual Logger (PIML) appropriate data. You can also collect provides a secure and scalable solution to record such data using PCs and hand held barcode or RFID data itself as PI values devices. Manually entered data can then be validated, uploaded to the PI Server, and fully with scan time as the timestamp. leveraged by the PI System just like any other PI System data. Data collection grouping Data collection items can be configured Overview in a hierarchy to reflect your plant site, PIML has many features to support manual input data collection, including: work area, process unit, equipment • Flexible scheduling: Data collection schedules such as hourly, daily, weekly, monthly, and yearly can be configured, for example: collect Chiller Compressor log components, building floors, etc. every Tuesday at 10:00 a.m. Task instructions • lists can be pre-configured to make data entry faster and easier. PIML supports making web pages to show SOP (standard operating procedures) or • Lab results: Lab values can be time-stamped to the time when the sample was collected. task instructions for data entry (including equipment images) available to users Configurable templates: Text entries such as failure codes, comments, and pick- • Multi-user support: A single data entry task can be accessed by different users as they’re collecting data. PIML also from separate networked PCs to allow lab results entry or to allow data review by supports other standard browser and supervisors who aren’t located near the data collection site. media functions via hyperlinks. • Support for future data: Future data can be collected as part of normal data entry and automatically queued for sending to the PI System. Data validation during data entry PIML performs automatic data validation • Operator presence confirmation: Barcode scans can be verified and logged prior to data entry in the field. This feature is available on select hardware. and supports limit checks including High, HiHi, Low, LoLo and Delta. If data falls outside the defined limit, customizable alert messages are displayed and users can also be prompted to enter required comments for the out-of-range values. Submit and approve workflow Manually entered data can be submitted for review and approval prior to being uploaded to the PI System. Collect multiple values for each item With PIML, multiple values (required for PIML data entry screen on a Windows® Mobile device (left) and a PC (right); limit violations are “as found” and “as left” entries, for field indicated by yellow or red shading. adjusted instrument calibrations, etc.) can be collected for any item. Features Continued Benefits Conditional data entry PIML can provide a number of benefits to your organization, including: Conditional expressions can be used to • specify if an item is due for collection; for example record the temperature and, if Greater field workforce productivity: Save valuable time during data collection with features like barcode scan navigation and “just-in- time” task instructions. • More thorough operations analysis: Use manually collected data with temperature is below freezing, then record automatically collected PI System data (i.e. data instrumentation systems and valve position. interfaces) for comprehensive analysis and a complete operational picture. Field collected equipment and process/lab data can also be integrated with enterprise Ad hoc data entry Using PIML’s ad hoc mode, field systems such as SAP and IBM® Maximo®. • Lower cost data collection: PIML provides an inexpensive way to enter lab data operators can collect any data, at any time, for the PI System. PIML can also be used to gather data from pilot runs, the start-up regardless of whether or not it’s due for of new or overhauled equipment, etc. which then allows for performance comparisons collection. during routine production runs. Security and audit trail Digital signatures can be associated with each value or comment. PIML also supports separate permissions for data entry and administration. Also, PIML can automatically log all important changes to configuration and data. Wireless and disconnected Using PCs and mobile devices, manual data can be collected while disconnected from the PI Server and later sent to the PI Server via a wired connection or wirelessly using the built-in PIML web services. PIML data - shown above in a browser using PI WebParts - includes operator comments, 10-day collection history, and a trend. The readings and the trend dynamically update based on the item Multiple hardware options selected in the hierarchy. PIML can be used with PCs, tablet devices, and handheld devices including those with barcode scanners and RFID readers. About OSIsoft OSIsoft (www.osisoft.com) delivers the PI System, the industry standard in enterprise infrastructure, for management of real-time data and events. With installations in 107 countries spanning the globe, the OSIsoft PI System is used in manufacturing, energy, utilities, life sciences, data centers, facilities, and the process industries. This global installed base relies upon the OSIsoft PI System to safeguard data and deliver enterprise- (Left) Handheld device with Windows Mobile wide visibility into operational, manufacturing and business data. The PI System enables 6 Professional. users to manage assets, mitigate risks, comply with regulations, improve processes, drive (Center) Wi-Fi enabled Windows Mobile innovation, make business decisions in real time, and to identify competitive business and device with barcode scanner. market opportunities. Founded in 1980, OSIsoft, LLC is headquartered in San Leandro, (Right) Wireless enabled Tablet PC with CA, with operations worldwide and is privately held. Windows XP. Disclaimer: OSIsoft, LLC does not endorse any device manufacturer or vendor; images shown are for illustration purpose only. © Copyright 2010 OSIsoft, LLC | 777 Davis Street, San Leandro, CA 94577 | www.osisoft.com DSMLEN-110210