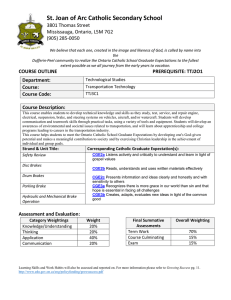

SEW-Disc Brakes / Drive Engineering – Practical Implementation

advertisement