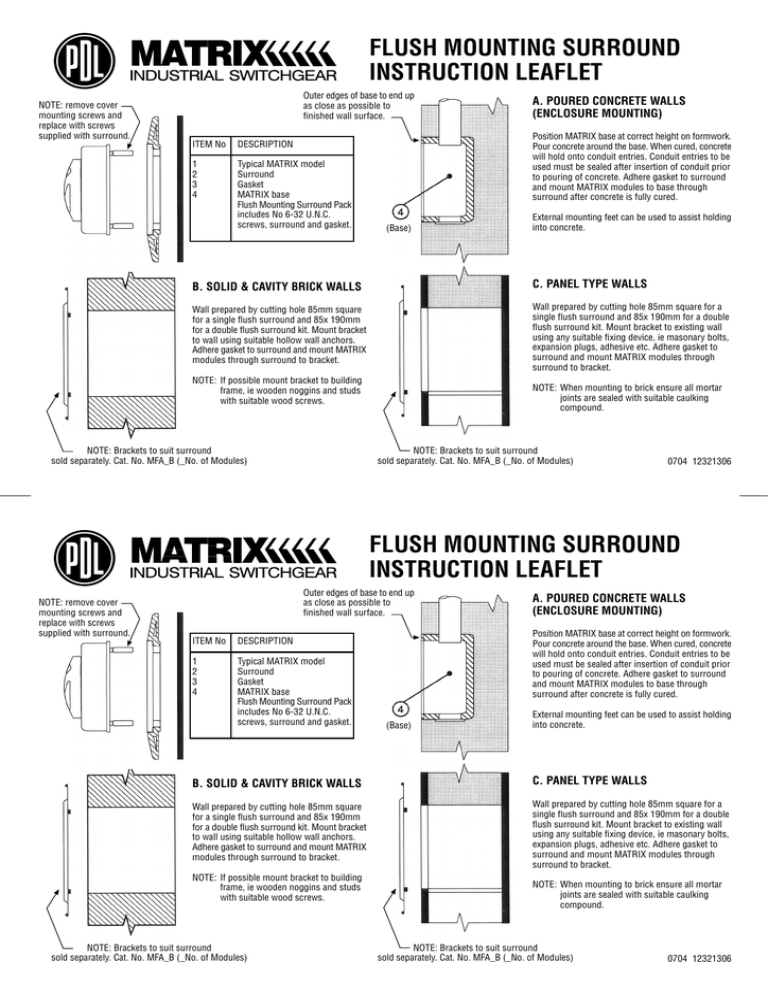

PDL Matrix Industrial Switchgear Flush Mounting Surround

advertisement

FLUSH MOUNTING SURROUND INSTRUCTION LEAFLET Outer edges of base to end up as close as possible to finished wall surface. NOTE: remove cover mounting screws and replace with screws supplied with surround. ITEM No DESCRIPTION 1 2 3 4 Typical MATRIX model Surround Gasket MATRIX base Flush Mounting Surround Pack includes No 6-32 U.N.C. screws, surround and gasket. A. POURED CONCRETE WALLS (ENCLOSURE MOUNTING) Position MATRIX base at correct height on formwork. Pour concrete around the base. When cured, concrete will hold onto conduit entries. Conduit entries to be used must be sealed after insertion of conduit prior to pouring of concrete. Adhere gasket to surround and mount MATRIX modules to base through surround after concrete is fully cured. (Base) External mounting feet can be used to assist holding into concrete. B. SOLID & CAVITY BRICK WALLS C. PANEL TYPE WALLS Wall prepared by cutting hole 85mm square for a single flush surround and 85x 190mm for a double flush surround kit. Mount bracket to wall using suitable hollow wall anchors. Adhere gasket to surround and mount MATRIX modules through surround to bracket. Wall prepared by cutting hole 85mm square for a single flush surround and 85x 190mm for a double flush surround kit. Mount bracket to existing wall using any suitable fixing device, ie masonary bolts, expansion plugs, adhesive etc. Adhere gasket to surround and mount MATRIX modules through surround to bracket. NOTE: If possible mount bracket to building frame, ie wooden noggins and studs with suitable wood screws. NOTE: Brackets to suit surround sold separately. Cat. No. MFA_B (_No. of Modules) NOTE: When mounting to brick ensure all mortar joints are sealed with suitable caulking compound. NOTE: Brackets to suit surround sold separately. Cat. No. MFA_B (_No. of Modules) 0704 12321306 FLUSH MOUNTING SURROUND INSTRUCTION LEAFLET Outer edges of base to end up as close as possible to finished wall surface. NOTE: remove cover mounting screws and replace with screws supplied with surround. ITEM No DESCRIPTION 1 2 3 4 Typical MATRIX model Surround Gasket MATRIX base Flush Mounting Surround Pack includes No 6-32 U.N.C. screws, surround and gasket. A. POURED CONCRETE WALLS (ENCLOSURE MOUNTING) Position MATRIX base at correct height on formwork. Pour concrete around the base. When cured, concrete will hold onto conduit entries. Conduit entries to be used must be sealed after insertion of conduit prior to pouring of concrete. Adhere gasket to surround and mount MATRIX modules to base through surround after concrete is fully cured. (Base) External mounting feet can be used to assist holding into concrete. B. SOLID & CAVITY BRICK WALLS C. PANEL TYPE WALLS Wall prepared by cutting hole 85mm square for a single flush surround and 85x 190mm for a double flush surround kit. Mount bracket to wall using suitable hollow wall anchors. Adhere gasket to surround and mount MATRIX modules through surround to bracket. Wall prepared by cutting hole 85mm square for a single flush surround and 85x 190mm for a double flush surround kit. Mount bracket to existing wall using any suitable fixing device, ie masonary bolts, expansion plugs, adhesive etc. Adhere gasket to surround and mount MATRIX modules through surround to bracket. NOTE: If possible mount bracket to building frame, ie wooden noggins and studs with suitable wood screws. NOTE: Brackets to suit surround sold separately. Cat. No. MFA_B (_No. of Modules) NOTE: When mounting to brick ensure all mortar joints are sealed with suitable caulking compound. NOTE: Brackets to suit surround sold separately. Cat. No. MFA_B (_No. of Modules) 0704 12321306