Replenishing, Oxygen System

advertisement

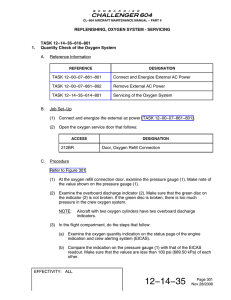

CL−605 AIRCRAFT MAINTENANCE MANUAL − PART II REPLENISHING, OXYGEN SYSTEM - SERVICING 1. TASK 12−14−35−610−801 Quantity Check of the Oxygen System A. Reference Information REFERENCE B. DESIGNATION TASK 12−00−07−861−801 Connect and Energize External AC Power TASK 12−00−07−861−802 Remove External AC Power TASK 12−14−35−614−801 Servicing of the Oxygen System Job Set−Up (1) Connect and energize the external ac power (TASK 12−00−07−861−801). (2) Open the oxygen service door that follows: ACCESS 212BR C. DESIGNATION Door, Oxygen Refill Connection Procedure Refer to Figure 301 and Figure 302. (1) At the oxygen refill connection door, examine the pressure gauge (1). Make note of the value shown on the pressure gauge (1). (2) Examine the overboard discharge indicator (2). Make sure that the green disc on the discharge indicator (2) is intact. If the green disk is out, it indicates that an overpressure condition of the oxygen system occurred. NOTE: If an overpressure condition of the oxygen system occurred, return the oxygen cylinder to the authorized facility for servicing. (3) In the flight compartment, do the steps that follow: (a) Examine the oxygen indication on the status page of the engine indication and crew alerting system (EICAS). (b) Compare the indication on the cylinder pressure gauge with the indication on the EICAS readout. EFFECTIVITY: ALL 12−14−35 Page 301 Nov 28/2008 CL−605 AIRCRAFT MAINTENANCE MANUAL − PART II (c) Compare the indication on the cylinder pressure gauge with the indication on the oxygen service−door pressure gauge (1). (d) Make sure that the values on the service panel gauge and the EICAS indication are within ±50 psi (344 kPa) of the oxygen bottle gauge. (e) Make sure that the crew oxygen system is fully pressurized (Figure 302). (4) If the oxygen system is not fully pressurized, do the servicing of the oxygen system (TASK 12−14−35−614−801). (5) Make sure that the indications that follow do not show on the status page on the EICAS: − LOW OXY PRESS − PAX OXY ON (6) Remove the external ac power (TASK 12−00−07−861−802). D. Close Out (1) Remove all tools, equipment, and unwanted materials from the work area. (2) Close the oxygen service door that follows: ACCESS 212BR DESIGNATION Door Oxygen Refill Connection EFFECTIVITY: ALL 12−14−35 Page 302 Nov 28/2008 CL−605 AIRCRAFT MAINTENANCE MANUAL − PART II 2 A B C DMM1214353_001 1 Quantity Check of the Oxygen System − Servicing Figure 301 EFFECTIVITY: ALL 12−14−35 Page 303 Nov 28/2008 CL−605 AIRCRAFT MAINTENANCE MANUAL − PART II TEMPERATURE CHART FULLY PRESSURIZED LIMIT CURVE 2000 1950 OXYGEN PRESSURE (PSI) 1900 1850 1800 1750 1700 1600 10 0 20 30 40 AMBIENT TEMPERATURE IN OXYGEN CYLINDER AREA (°C) 50 DMM1214353_011 1650 Quantity Check of the Oxygen System − Servicing Figure 302 EFFECTIVITY: ALL 12−14−35 Page 304 Nov 28/2008 CL−605 AIRCRAFT MAINTENANCE MANUAL − PART II 2. TASK 12−14−35−614−801 Servicing of the Oxygen System A. Reference Information REFERENCE B. DESIGNATION TASK 12−00−07−861−802 Remove External AC Power TASK 12−00−10−480−801 Connect Ground Air Supply TASK 12−14−35−610−801 Quantity Check of the Oxygen System TASK 21−00−00−862−801 Pressurize the Air Conditioning System with the Auxiliary Power Unit (APU) TASK 35−00−00−910−801 Oxygen Safety Precautions Tools and Equipment REFERENCE GSE 12−30−02 Adaptor, Oxygen System GSE 24−00−24 Tag, Circuit Breaker NOTE: C. DESIGNATION Refer to the Illustrated Tool and Equipment Manual to make sure that you use the correct equipment configuration. Consumable Materials REFERENCE 05−038 DESIGNATION Oxygen, Aviator’s Breathing, Gas MANUFACTURERS’ REFERENCE AND/OR SPECIFICATION MIL−O−27210 Type 1 EFFECTIVITY: ALL 12−14−35 Page 305 May 29/2009 CL−605 AIRCRAFT MAINTENANCE MANUAL − PART II D. Job Set−Up CAUTION: BEFORE YOU REPLENISH THE OXYGEN SYSTEM, MAKE SURE THE AMBIENT TEMPERATURE IS NOT ABOVE 45 °C. IF THIS OCCURS, OXYGEN CYLINDER CAN BECOME TOO HOT AND CAUSE DAMAGE TO UNIT. (1) Measure the cabin temperature. If the cabin temperature is above 45°C, cool down the cabin temperature below 45°C using the external ground air supply unit or the APU. NOTE: − The cabin temperature can be monitored with the cabin temperature readout on the EICAS multi−function display (MFD). Connect the ground air supply and push in the L and R PACK switch/light (TASK 12−00−10−480−801). or − Pressurize the air conditioning system with the auxiliary power unit (APU) (TASK 21−00−00−862−801). WARNING: BEFORE YOU DO MAINTENANCE ON THE OXYGEN SYSTEM, MAKE SURE THAT THE EXTERNAL ELECTRICAL POWER IS NOT CONNECTED. MAKE SURE THAT ALL PRIMARY CIRCUIT BREAKERS FOR THE AIRCRAFT BATTERIES ARE OPEN AND SAFETIED. IF YOU ENERGIZE THE ELECTRICAL POWER SOURCE, OR A SPARK OCCURS NEAR AN OXYGEN LEAK, A FIRE/EXPLOSION CAN OCCUR. THIS CAN CAUSE INJURY TO PERSONS, AND DAMAGE TO EQUIPMENT. (2) Make sure that the external ac electrical power is not connected (TASK 12−00−07−861−802). (3) Make sure that the BATTERY MASTER switch in the flight compartment is set to OFF. (4) Open, safety and tag the circuit breakers that follow: LOCATION CB NUMBER CB NAME ZONE CBP−2 M3 BATT BUS POWER SENSE 222 CBP−2 M4 RCCB CONT MAIN BATT 222 CBP−2 M5 RCCB CONT APU BATT 222 CBP−2 M7 FEED 1 BATT BUS 222 CBP−2 M9 FEED 2 BATT BUS 222 EFFECTIVITY: ALL 12−14−35 Page 306 Nov 28/2008 CL−605 AIRCRAFT MAINTENANCE MANUAL − PART II (5) Obey all the oxygen safety precautions (TASK 35−00−00−910−801). (6) Open the oxygen refill connection door (212BR). E. Procedure Refer to Figure 303. WARNING: MAKE SURE THAT HANDS AND CLOTHES OF OPERATING PERSONNEL AND ALL EQUIPMENT, PLUMBING AND FITTINGS USED IN OXYGEN CHARGING ARE COMPLETELY CLEAN OF OIL, GREASE AND SOLVENTS - THESE MAY GET ON FIRE INSTANTLY OR EXPLODE WHEN IN CONTACT WITH HIGH PRESSURE OXYGEN. TO KEEP THE OXYGEN SYSTEM FREE FROM CONTAMINATION, THE FILLER VALVE SHALL BE CAPPED AT ALL TIMES, EXCEPT WHEN CONNECTED TO THE CHARGING CART. CAUTION: THE OXYGEN PRESSURE IN THE CYLINDER MUST NOT BE LESS THAN 50 PSI (345 KPA) AT ANY TIME. IF THIS OCCURS, THE OXYGEN CYLINDER MUST BE REMOVED AND SENT BACK TO THE MANUFACTURER TO BE PURGED. (1) Make sure that each masks are correctly stowed and that the regulators are set to N. (2) Remove the dust cap (1). (3) Install the oxygen system adaptor on the oxygen filler valve (2). (4) Connect the filler line of the oxygen cart to the oxygen system adaptor. CAUTION: MAKE SURE THAT THE OXYGEN SYSTEM PRESSURE IS NOT MORE THAN 1850 PSI (12755 KPA) AT 70 °F (21 °C). IF THE OXYGEN SYSTEM PRESSURE IS MORE, IT CAN CAUSE DAMAGE TO THE SYSTEM. (5) Charge the oxygen cylinder at a rate not more than 200 psi/min (1378.96 kpa/min) until the oxygen cylinder is fully charged as per servicing placard and oxygen pressure gauge (3). NOTE: Make sure to allow a cool down period of 30 to 45 minutes, to make sure that the oxygen system is fully charged. (6) Close the supply valve on the oxygen servicing cart to OFF. (7) Disconnect the servicing cart and oxygen system adaptor from the aircraft. (8) Immediately install the dust cap (1) on the oxygen filler valve. EFFECTIVITY: ALL 12−14−35 Page 307 Nov 28/2008 CL−605 AIRCRAFT MAINTENANCE MANUAL − PART II (9) Remove the tags and close the circuit breakers that follow: LOCATION CB NUMBER CB NAME ZONE CBP−2 M3 BATT BUS POWER SENSE 222 CBP−2 M4 RCCB CONT MAIN BATT 222 CBP−2 M5 RCCB CONT APU BATT 222 CBP−2 M7 FEED 1 BATT BUS 222 CBP−2 M9 FEED 2 BATT BUS 222 (10) Do a quantity check of the oxygen system (TASK 12−14−35−610−801). (11) Close the oxygen refill connection door (212BR). F. Close Out (1) Remove all tools, equipment, and unwanted materials from the work area. EFFECTIVITY: ALL 12−14−35 Page 308 Nov 28/2008 CL−605 AIRCRAFT MAINTENANCE MANUAL − PART II 3 2 1 DMM1214353_002 3 Servicing of the Oxygen System − Servicing Figure 303 EFFECTIVITY: ALL 12−14−35 Page 309 Nov 28/2008