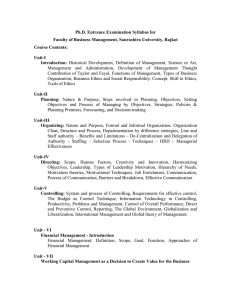

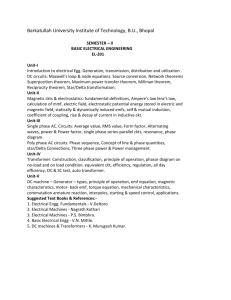

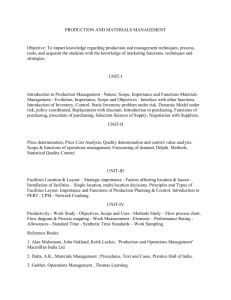

Syllabus for B.Tech. Mechanical Engineering/Production Engineering

advertisement