Welcome to Chalmers University of Technology Technology

advertisement

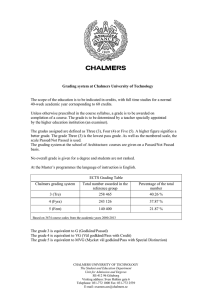

Chalmers University of Technology Welcome to Chalmers University of Technology CE1 Chalmers University of Technology CHALMERS UNIVERSITY OF TECHNOLOGY • Founded 1829 • Numbers: – – – – CE2 Students 9000 Doctor students 550 Personnel 2200,, of which 200 pprofessors Turnover of research 1500 MSEK, of which 30 % is internal and 70 % external fundung Chalmers University of Technology Research at Department of Energy & Environment, Division of Energy Technology, CTH -------------------------------• Fuel conversion (combustion, pyrolysis and gasification), especially biofuels • CO2 reduction methods • Topics related to energy systems CE3 Chalmers University of Technology DIVISION OF ENERGY TECHNOLOGY RESEARCH GROUPS WITH RELATION TO COMBUSTION • Prof. A. Lyngfelt---Chemical looping combustion for CO2 reduction d i • Prof. F. Johnsson---FBC fluid dynamics and CO2 reduction by oxyfuel combustion • Assc. Prof. L.-E. Åmand---Emissions from FBC, especially co-combustion & synergy effects g • Assc. Prof. H. Thunman—Biofuel conversion modelling. fixed and fluidized bed, gasification • Prof. B. Leckner----Support activities, modelling of gasification CE4 Chalmers University of Technology LARGE SCALE TEST FACILITIES AT THE DIVISION • 100 kW oxy-fuel oxy fuel furnace for gas or pulverised fuel • 12 MW circulating fluidised bed for coal, wood, sludge etc. • 2-4 MW gasifier for solid fuels • 10 kW chemical looping cycle combustor CE5 Chalmers University of Technology THE OXY-FUEL RESEARCH GROUP IN FRONT OF THE TEST RIG (F. Johnsson) CE6 Chalmers University of Technology Chalmers CFB 12 MW research boiler for combustion research and for heat production for the campus. Has been used in several EU projects. (L.-E Åmand) oo 5 oo 4 6 Front wall Rear wall o o 7 3 o o 8 1 Experimental data on industrial scale, many years experience in experimental methods under full-scale conditions. 2 CE7 Chalmers University of Technology INTEGRATION OF A 2 MW BIOMASS GASIFIFIER IN A CFB BOILER (H. Thunman) Heat, Electricity, Steam Heat, Electricity, Steam Flue gas Flue gas Air CE8 Hot bed material Fuel Hot bed material Bio Product Gas Biomass Fuel Air Fluidization gas (Steam or Bio Producer Gas or …) Chalmers University of Technology CHEMICAL LOOPING COMBUSTION: 10kW test unit (A. Lyngfelt) 15 13 3 6 12 5 2 12 12 4 14 5 1 11 1) air reactor, 2) riser, 3) cyclone, 4) fuel reactor, 5) upper and lower particle locks, 6) water trap, 7) nitrogen 8) natural gas, 9) argon, 10) air, 11) preheater, h t 12) heating coils, 13) finned tubes for cooling of gas streams, 14) filters 15) connection to chimney. 7 8 9 10 CE9 May 5 Afternoon: Fluidised bed combustion and related topics (Filip Johnsson and Lars Erik Åmand and co workers) May 6 Morning: CO2 removal by fluidised bed chemical looping cycle (Anders Lyngfelt and co-workers) Chalmers University May 6 Afternoon: CO2 removal by oxy-fuel combustion (PC and FBC boilers) (Klas Andersson and Filip Johnsson and co-workers). of Technology POST MEETING MEETINGS •May 5 Morning: Fluidised bed gasification (Henrik Thunman and co-workers) •May 5 Afternoon: Fluidised bed combustion and related topics (Filip Johnsson and Lars-Erik Åmand and co-workers) •May 6 Morning: CO2 removal by fluidised bed chemical looping cycle (Anders Lyngfelt and co-workers) •May 6 Afternoon: CO2 removal by oxy-fuel combustion (PC and FBC boilers) (Klas Andersson and Filip Johnsson and co-workers). CE10