CAT L-200 24 Technical Information pages 783

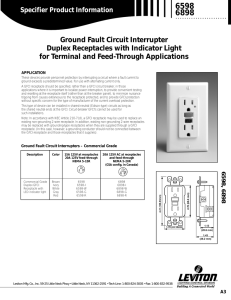

advertisement