Class 17 – X-ray Diffraction ray Diffraction Class 17 Class 17 – X

advertisement

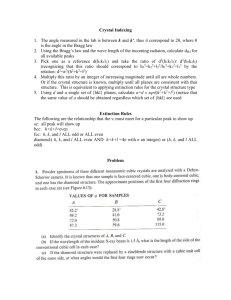

Class 17 – X-ray Diffraction Reading • Chapter 12 in DeGraef and McHenry • Chapter Ch t 3 in i Engler E l and d Randle R dl • Chapter 6 in DeGraef and McHenry (I WILL ASSUME THAT YOU KNOW ABOUT THIS CONCEPT ALREADY! IF NOT, READ IT!) Prof. M.L. Weaver Review: X-Ray Diffraction • XRD is a powerful experimental technique used to determine the – crystal structure and its lattice parameters (a (a, b, b c, c ) ) and – spacing between lattice planes (hkl Miller indices) this interplanar spacing (d) is the distance between parallel planes of atoms or ions. • Diffraction is result of radiation’s being scattered by a regular array of scattering centers whose hose spacing is abo aboutt same as the of the radiation radiation. • Diffraction gratings must have spacings comparable to the wavelength of diffracted radiation. We know that atoms and ions are on the order of 0.1 0 1 nm in size, size so we think of crystal structures as being diffraction gratings on a sub-nanometer scale. • • For X-rays, atoms are scattering centers (photon interaction with an orbital electron in the atom). Spacing (dhkl) is the distance between parallel planes of atoms…… 2 XRD to Determine Crystal Structure & Interplanar Spacing Recall incoming X-rays diffract from crystal planes: reflections must be in phase for a detectable d bl signal i l is scattering (Bragg) angle extra distance traveled by wave “2” d Adapted from Fig. 3.37, Callister & Rethwisch 3e. i.e., for diffraction to occur, x-rays scattered off adjacent crystal planes must be in phase: spacing between planes Measurement of critical angle, c, allows computation of interplanar spacing (d) X-ray intensity (f (from detector) d 2 sin c B Bragg’s ’ L Law(1) d hkl cubic c a h2 k 2 l 2 (2) Combine (1)+(2): (Bragg’s Law is not satisfied) 3 Recall the interplanar spacings (dhkl) for the 7 crystal y systems y •As crystal symmetry decreases, the number of peaks observed increases: •Cubic crystals, highest symmetry, fewest peaks. •Triclinic crystals, lowest symmetry, large number of peaks. 4 Geometry of XRD (F.Y.I) •A single wavelength of x-ray radiation is often used to keep the number of diffraction peaks to a small workable number, since samples often consists of many small crystal grains orientated randomly. •The diffracted beam intensity is monitored electronically by a mechanically driven scanning radiation detector. Usually graphite to focus beam like a parabolic mirror Collimate beam High Z to max. absorption. Removing unwanted radiation X-ray Source (fi ed) (fixed) Bragg angle = Diffraction angle, what’s measured experimentally = 2 •Counter/detector is rotated about O-axis; 2 is its angular position. •Counter and specimen are mechanically coupled such that a rotation of the specimen through is accompanied by a 2 rotation of the counter. •This assures that the incident and reflection angles are maintained equal to one another. More on Bragg’s Law •Bragg’s Law is a necessary but insufficient condition for diffraction. •It only defines the diffraction condition for primitive unit cells, e.g. P cubic, P tetragonal, etc., where atoms are onlyy at unit cell corners. •Crystal structures with non-primitive unit cells have atoms at additional lattice (basis) sites. •These extra scattering centers can cause out-of-phase scattering to occur at certain Bragg angles. •The net result is that some of the diffraction predicted by Bragg’s Law (eq. 1) does not occur, i.e. certain sets of p planes do not exist ((forbidden reflections). ) •Selection (or Reflection) rules: Bravais Lattice Example Compounds Allowed Reflections Forbidden Reflections Primitive Cubic Simple Cubic (-Po) Any h,k,l None Body-Centered Cubic Body-Centered Cubic metal h+k+l even h+k+l odd Face-Centered Cubic Face-Centered Cubic metal h,k,l all odd or all even h,k,l mixed odd or even Face-Centered Cubic NaCl-rocksalt, ZnS-zincblende h,k,l all odd or all even h,k,l mixed odd or even F Face-Centered C t dC Cubic bi Si Ge Si, G - Diamond Di d cubic bi As FCC, A FCC but b t if allll even and h+k+l≠4n, then absent (n is integer) h,k,l h k l mixed i d odd dd or even and if all even and h+k+l≠4n Primitive Hexagonal Hexagonal closed packed metal All other cases h+2k=3n, l odd These rules are calculated based on atomic scattering factors and structure factors, which we will discuss next class and next week (you will also see on final exam). 6 Selection Rules for Cubic Crystals d hkl a h k l 2 2 2 a S where “S” is reflection or line #, e.g. (100) is 1st order reflection and (200) is 4th order reflection reflection. As we will determine later when we calculate the structure factors, these selection rules also hold for other Bravais lattices, e.g. I-tetragonal, F-orthorhombic, etc. P I F S ((hkl)) S ((hkl)) S ((hkl)) 1 100 - - - - Odd+even 2 110 2 110 - - Odd+even 3 111 - 3 111 All odd 4 200 4 200 4 200 All even 5 210 - - - - Odd+even 6 211 6 211 - - Odd+even 7 - - - - - 8 220 8 220 8 220 9 221,300 - All even - Odd+even Odd+even Odd eve 10 310 10 310 11 - - 11 311 All odd 12 222 12 222 All even 311 12 222 7 Example of XRD Pattern •The unit cell size and geometry may be resolved from the angular positions of the diffraction peaks. •When the distance between the peak spacings are all pretty much the same (2) it is likely cubic. •The arrangement of atoms within the unit cell is associated with the relative intensities of these peaks z Inntensity (relative) c a z (110) c y (110) a b x z (200) b c y x Diffraction pattern for ppolycrystalline y y -iron (BCC) a x d-spacing decreases according to Bragg’s Law (211) b y (211) (200) Diffraction angle 2 h+k+l even are only allowed according to previously shown selection rules for BCC. 8 Review of Systematic Absences in the Diffraction Patterns of 4 Cubic Structures =S= When indexing XRD data for your material always try cubic first (least amount of diffracting planes since most symmetric lattice parameters). 9 X-Ray Diffraction for Tetragonal, e go andd Orthorhombic O o o b c Crystals C ys s Hexagonal Bragg’s Law (1): d (1) 2 sin c a (2) Plane spacing d hkl h 2 k 2 l 2 for cubic crystals Plane spacings for: (4) (5) (6) Combined (1) and (2): 2 sin 2 2 2 2 2 If crystal is tetragonal with a=a≠c then (1) and (4) become: n 2 or sin 2 (h k l ) 2 2 2 2 2 2 2 2 4 a 2 a h k l (7) (3) sin 2 h k 2 l 2 4a 4c For a particular incident x-ray wavelength and cubic with a=a≠c then (1) and (5) become: crystal of unit cell size a, a this equation predicts all possible If crystal is hexagonal 2 2 2 Bragg angles at which diffraction can occur from planes 2 2 2 sin 2 h k hk 2 l (8) (hkl). 3a 4c If crystal is orthorhombic with a≠b≠c then (1) and (6): Diffraction planes are determined solely by the shape 2 2 2 2 2 2 2 sin 2 (h ) 2 (k ) 2 (l ) (9) and size (lattice parameters) of the unit cell. 4a 4b 4c • Intensities of diffracted beams are determined by positions of the atoms within the unit cell. Thus, we must measure the intensities if we are able to obtain any information at all about atom positions. (Intensities (I) ); i.e.,, I is p proportional p to F). ) are related to Structure Factor ((F); • We will determine that for many crystals there are particular atomic arrangements which reduce the intensities of some diffracted beams to zero, i.e. no diffracted beam at the angle () predicted by Equations (3), (7), (8), (9), etc., which means F=0. 10 The Effect of Cell Distortion (Symmetry) on XRD Patterns • As the symmetry of crystal decreases more peaks are seen, e.g. cubic triclinic. • Similar with cell distortion. If distort cubic I along [001] by 4% so c is i now, 4.16Å 4 16Å gett I tetragonal. l • This decreases symmetry more, and shifted diffraction lines are formed (shown in the middle for tetragonal). • If now stretch 8% along [010] axis with a=4.00Å, b= 4.32Å, and c= 4.16Å 4 16Å to get orthorhombic I which lowers symmetry even more thus adding more diffraction lines (shown right). • The increase in number of lines is due to the introduction of new hkl plane d-spacings, caused by non-uniform distortion. • Thus in cubic cell, cell the (200) (200), (020) and (002) planes all have the same spacing and only one line is formed, called the (200) line. However, this line splits into two when the cell becomes tetragonal since now the (002) plane spacing differs from the other two. • When the cell becomes orthorhombic, all three spacings are different and three lines are formed. • Common in phase transformations, e.g. carbon steel slowly cooled get Ferrite (BCC) Cementite (orthor.), and quench from austentite ((FCC)) martensite ((I-tetragonal). g ) • In disorder-order reactions (CuAu), cubic in disordered state but becomes either tetragonal or orthorhombic (depending on temperature) when ordered. 11 11 Example: Phase Transformations in ZrO2 Low-pressure forms of ZrO2. Red=O Blue=Zr Property P Lattice parameters (Å) a b c Temperature (K) Coordination Volume (Å3) Density (g/cc) Space Group C bi ZrO Cubic Z O2 T Tetragonal l ZrO Z O2 M Monoclinic li i ZrO Z O2 5.034 5.034 5.034 >2570 Zr=8; O1=4; O2=4 127.57 6.17 Fm-3m 5.037 5.037 5.113 1400 to 2570 Zr=8; O1=4; O2=4 129.73 6.172 P42/nmc 5.098 5.171 5.264 <1400 Zr=7; O1=3; O2=4 136.77 5.814 P21/c XRD scan of a tetragonal ZrO2 thin film taken from UNT’s Rigaku Ultima III high-resolution XRD 12 Monoclinic Cubic 13